OEM Plastic Part Manufacturing: From Design Assistance to Mass Production

Supplying plastic parts to OEMs requires more than injection molding alone. You need expertise in design, prototyping, tooling, quality control, and global logistics. PrimeCustomParts.com delivers that end-to-end solution. This guide explains every step and decision point, with actionable design tips, prototyping options, quality standards, and how Prime supports clients worldwide.

Key Design Tips for Manufacturability and Moldability

A successful OEM plastic part begins with smart design. Proper attention to manufacturability avoids mold issues, quality defects, and costly revisions.

Uniform Wall Thickness

- Target 0.8–4 mm for thermoplastics like ABS or PC.

- Consistent thickness prevents sink marks, warping, and shrinkage.

- Add ribs for structural support instead of thick solid sections.

- See Moldflow design best practices for more.

Draft Angles & Fillets

- Include 1–2° draft on vertical faces for easy ejection.

- Use radii of R0.5 mm or more in corners to reduce stress.

- Avoid sharp edges that trap resin or make filling difficult.

- Learn from Wikipedia’s “Draft (engineering)”.

Avoid Undercuts or Deploy Inserts

- Undercuts require sliders/collapsible cores—more complex tooling.

- Instead, use threaded inserts or snap-fit features.

- Read about inserts in injection molding on Protolabs.

Geometry Simplification

- Complex internal channels and textures trap air.

- Avoid long, thin bosses that warp during cooling.

- Balanced parting line placement ensures smooth mold split.

- Autodesk’s guide covers this: Mold Design Fundamentals.

Material-Informed Design

- Choose resin early to match design needs: strength, temp, finish.

- Reference MatWeb’s data library: MatWeb Material Search.

Adhering to these guidelines during design saves time and ensures quality in prototyping and mass production.

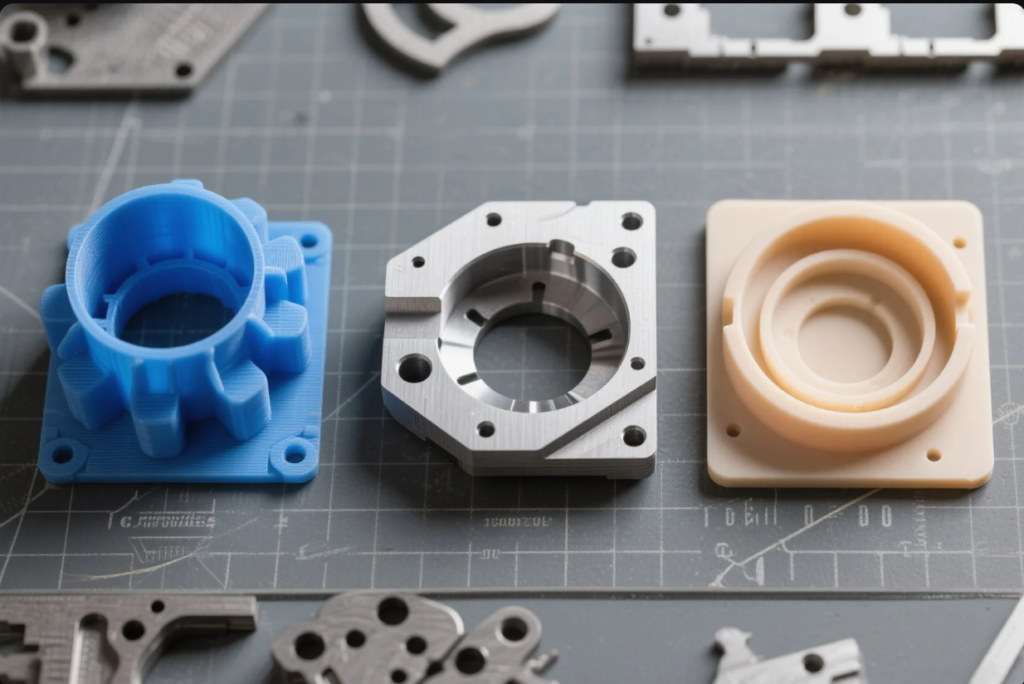

Prototyping Options: 3D Printing, Machining, and Soft Molds

Prototyping allows you to validate designs before committing to full tooling costs. Prime offers:

3D Printing

- Methods: SLS, SLA, FDM

- Materials: PLA, nylon-like, rigid composites

- Best for: Fit/form checks, ergonomic evaluation

- Drawbacks: Lower tolerance (\~±0.3 mm), not material-accurate

- Learn more: 3D Printing Materials Guide – Sculpteo

CNC Machining

- Produces parts from real resin in 5–7 days

- Tolerances: Typically ±0.02 mm

- Finish: Raw, bead-blasted, polished, laser-engraved

- Uses: Mechanical fit trials, functional stress testing

- Common materials: ABS, PC, POM, PEEK

- Info: CNC Machining Resources – Proto Labs

Soft Molds (Aluminum or Resin)

- Small-volume injection runs: 100–500 parts

- Real plastic properties: surface, shrink, tactile feel

- Bridges prototype to production

- Resource: Soft Tooling Explained – Plastics Technology

Strategically combining these methods accelerates design validation and risk reduction.

Quality Control Methods for Plastic Production (ISO, Tolerances, Testing)

Consistent quality is essential for OEM parts. Prime applies rigorous QC protocols:

ISO 9001 Quality Management

- Ensures traceability, logged parameters, and formal audits

- Follows ISO 9001:2015 standard

Dimensional Tolerance Testing

- CMM verifies dimensions to ±0.05 mm or ±0.02 mm

- First article inspections meet ISO 14253-1

Surface & Finish Checks

- SPI grades A1/A2, B2/B3, D1–D3 inspected visually

- Cosmetic defects tracked per AQL limits

Mechanical and Functional Testing

- Tensile, flex, impact, heat deflection tests per ASTM

- UV, chemical, and environmental aging tests performed as required

- Example: plastic parts tested by Underwriters Laboratories (UL)

Packaging & Traceability

- Moisture-barrier packaging, EPE foam, export labels

- Batch-coded with production info and verifiable history

These steps guarantee OEM components meet regulatory, reliability, and consistency expectations.

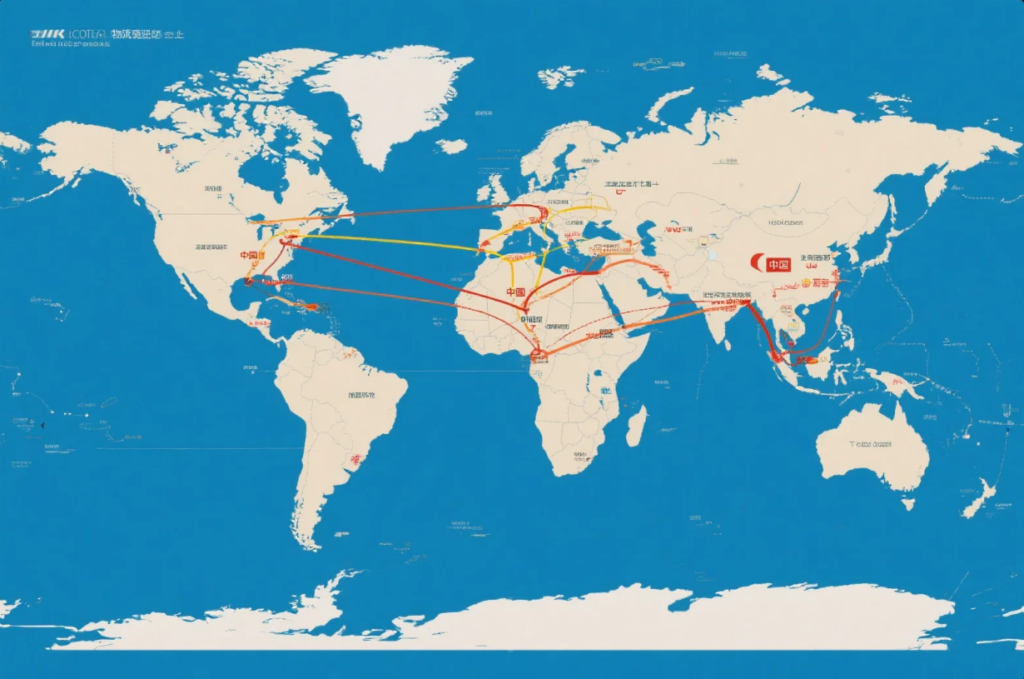

How We Serve OEM Clients Worldwide with Fast, Reliable Plastic Solutions

Prime offers a full-service, global-ready OEM manufacturing solution:

| Production Stage | Time to Deliver | Description |

|---|---|---|

| Inquiry & CAD Review | Within 24 hours | Submit STEP/IGES for DFM + quote |

| Prototype (3–10 days) | Add resin & functional testing | CNC, 3D print, or soft mold test parts |

| Main Tooling (10–15 days) | Build mold, gates, cooling channels | Steel or aluminum molds with validation |

| T1 Sampling & Approval (2–3 weeks) | Customer validation | Includes QC, usability, aesthetics |

| Mass Production Run (3–7 days/batch) | Full-scale manufacturing | Just-in-time or scheduled runs |

| QC & Packaging (1–2 days) | Package to OEM specs | International packaging & traceability |

| Global Shipping (5–30 days) | FedEx, DHL, sea freight | Compliance with export/import laws |

We serve US, Europe, Australia, Middle East, Latin America, Africa, and Southeast Asia, ensuring reliable logistics and customs compliance.

FAQs

How are mold revisions handled after tooling begins?

Minor changes possible; major revisions need tooling rework. We recommend freezing design post-prototype.

What mold life can I expect?

Steel molds produce 100k–1M+ shots; aluminum molds yield 10k–20k parts.

Do you support overmolding or multi-shot molding?

Yes—insert molding and dual-shot options supported with precise gating.

Can you assist with UL, RoHS, CE, and FDA certifications?

Absolutely. We provide compliant resin grades and documentation.

What testing standards are applied?

We use ASTM, ISO, UL, and FDA protocols depending on part requirements.

How fast is your quoting process?

Initial CAD review and quote delivered within 24 hours.

Contact PrimeCustomParts.com

📧 [email protected]

🌐 https://primecustomparts.com

Connect with Prime for:

- Free CAD review and DFM guidance

- Fast turnaround prototypes and soft molds

- Certified tooling and QC systems

- Scalable production runs

- Global shipping with export compliance

Conclusion

From early-stage design assistance to global mass production, PrimeCustomParts.com is your trusted partner. We guide your project though DFM optimization, prototypes, tool-making, QC, and full production—all with speed, quality, and transparency. OEMs gain confidence with a complete solution.

Submit your CAD today for a fully scoped prototype-to-production roadmap tailored to your needs.