Post-Processing for Injection Molded Parts: Finishing, Welding, and Testing Explained?

Injection molded parts often need extra steps—welding, surface treatment, testing, and validation—to meet performance, aesthetics, and regulatory requirements.

Selecting optimal post-processing ensures functional reliability, brand impact, and market compliance. Let’s explore welding options, finishing techniques, testing protocols, and certification essentials.

Ultrasonic welding vs. hot plate welding

Welding joins molded parts when single-shot molding can’t accommodate size, geometry, or inserts.

Ultrasonic Welding

Uses high-frequency mechanical vibrations (approx. 20–40 kHz) to instantaneously fuse compatible thermoplastics like ABS or PC—per ASTM D5376 and ISO 18187. Equipment from Branson ensures fast, clean welds under three seconds, ideal for electronics, toys, and medical disposables.

Pros: Speed, no consumables, clean

Cons: Needs energy‑director joint designs, less effective with thick parts

Hot Plate Welding

Heats part interfaces using a temperature-controlled tool (\~250–350 °C)—in accordance with ASTM D2899—then presses and cools. Suited for large enclosures, automotive ducts, or mixed polymers.

Pros: Strong bonds, works with varied materials

Cons: Longer cycles, needs trimming

| Welding Method | Cycle Time | Size | Material Flexibility | Weld Strength |

|---|---|---|---|---|

| Ultrasonic Welding | 1–3 s | Small–medium | Compatible amorphous | \~90–95% resin |

| Hot Plate Welding | 10–20 s | Medium–large | Wide (mixed polymers) | \~95–100% resin |

Equipment providers like Dukane offer full specs and best‑use guides.

Surface finishes: spray coating, laser marking, pad printing

Quality finishes enhance both form and function.

Spray Coating

Used for decorative or protective finishes—offered by PPG and DuPont with spray booths and ovens. While it improves aesthetics, VOC compliance with EPA VOC regulations is critical in production settings.

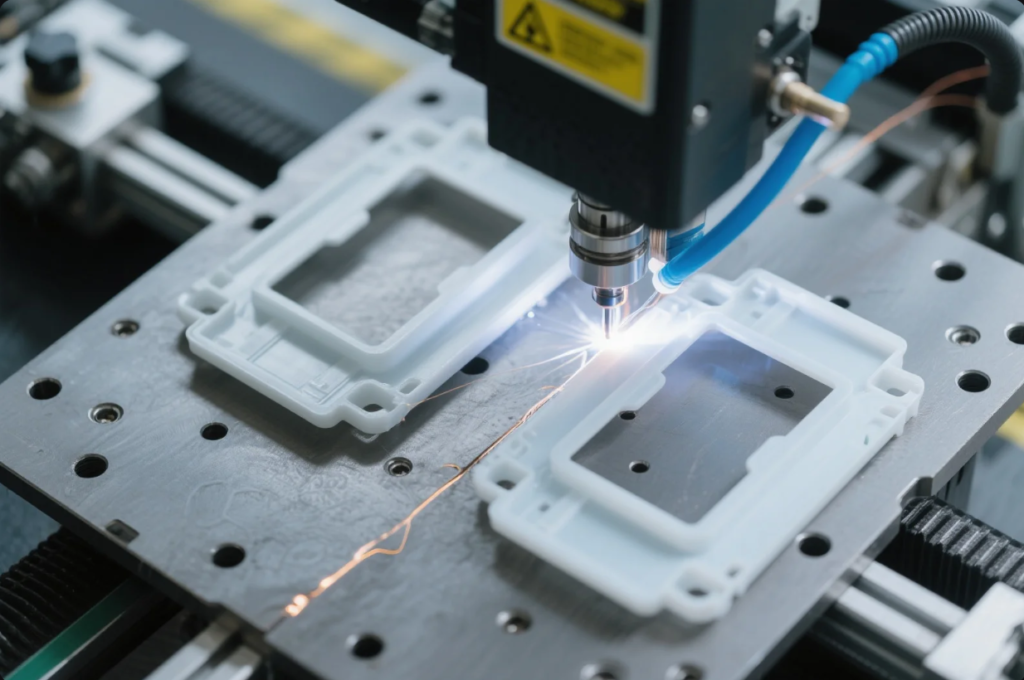

Laser Marking

Utilizes CO₂ or fiber lasers—no inks, permanent engravings. Standards from Trotec or Epilog support ISO 9001‑style traceability for serialized components.

Advantages: Durable, no consumables, vandal‑proof

Disadvantages: Higher initial cost, limited to certain resin types

Pad Printing

Transfers ink via silicone pads for logos and color accents. Leading ink suppliers include Siegwerk and Sun Chemical—choose FDA‑compliant formulations per 21 CFR 175.300.

Best Practices: Pre-treat surfaces using corona or plasma for better adhesion

Key quality tests: destructive & non‑destructive

Post-processing demands rigorous validation.

Destructive Testing

- Tensile/compression tests per ASTM D638 or ISO 527

- Impact resistance (Izod/Charpy) under ASTM D256

- Climate and aging tests per ISO 16750 for real-world durability

Non-Destructive Testing (NDT)

- Visual inspection for flash, sink marks, using ISO 9001 QC protocols

- X-ray/CT scanning for insert integrity or internal bubbles

- Ultrasonic bond testing for welded areas

- Leak testing per ASTM D6653 for gas-tight parts

A quality blend of NDT for production and destructive checks for validation ensures reliability and traceability.

Compliance essentials: ISO, FDA, automotive-grade testing

Meeting industry norms opens global markets.

ISO Standards

FDA Requirements

- Use FDA food‑contact resins under 21 CFR 177.xxx

- Pigments must comply with 21 CFR 178.3297

- Food safety guidelines reviewed in FDA food-contact resources

Automotive Testing

- Electronic module shells meet SAE standards like J1455 and J2690

- OEM benchmarks found in VW TL 526 spec sheets via VW Supplier Portal

Testing & Certification Labs

- Renowned labs: Intertek, UL, TÜV SÜD — with documented traceability and testing protocols for client audits

FAQs

-

Which welding method is fastest?

Ultrasonic welding completes welds in under 3 seconds per joint. -

Does laser marking damage resin?

When tuned properly, it yields high-contrast marks without surface degradation. -

Is destructive testing mandatory every batch?

Typically, destructive tests validate each batch, while every-part inspection uses non‑destructive methods. -

Can I weld dissimilar materials?

Hot plate welding supports mixed polymers; ultrasonic welding works only on compatible types. -

Do you provide compliance documentation?

Yes — ISO, FDA, SAE, UL/TUV test reports, and serial traceability are available on request.

Contact Us

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Conclusion

Effective post-processing combines correct welding, durable finishes, robust testing, and full compliance to deliver high‑quality plastic parts. Partner with Prime to receive production‑ready, standards‑compliant components—delivered on time and backed by traceable documentation.