Precision Casting (Lost Wax) vs Die Casting: What to Choose?

When it comes to producing high-quality metal components, two widely used casting methods often stand out: Precision Casting (also known as Lost Wax Casting) and Die Casting. Each has distinct strengths depending on the project’s requirements in terms of complexity, volume, cost, and performance. This guide explores their differences, ideal applications, and key decision-making factors.

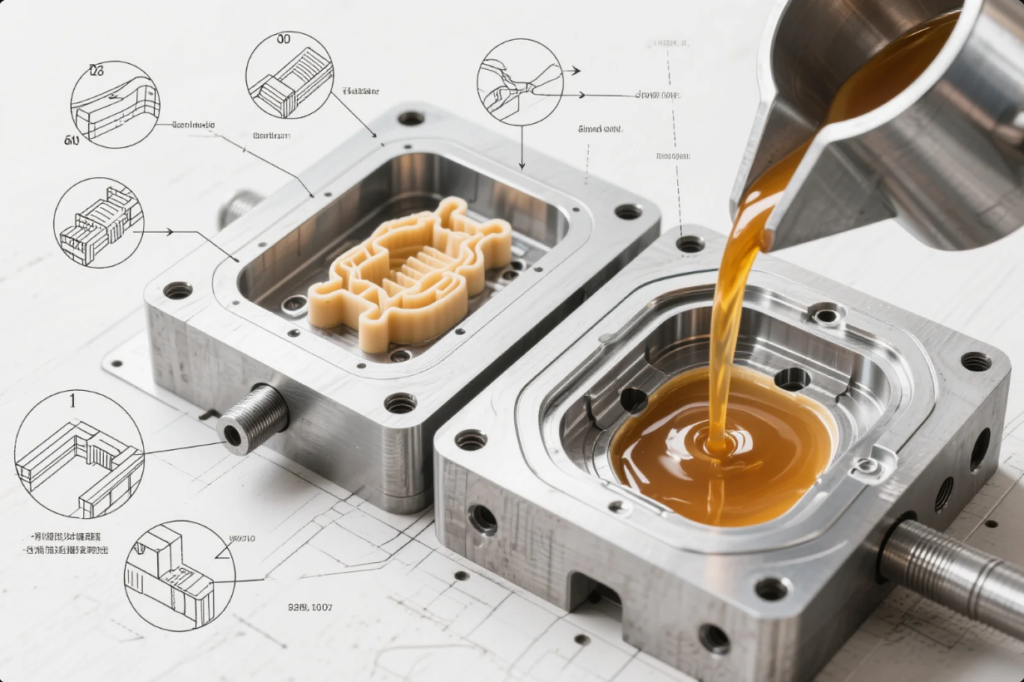

What is Precision Casting (Lost Wax)?

Precision casting, or investment casting, uses a wax pattern coated in ceramic to create a mold. Once the ceramic shell hardens, the wax is melted out, and molten metal is poured into the cavity.

🔍 Features:

- Excellent dimensional accuracy (±0.05 mm)

- Ideal for complex, intricate shapes

- Can cast ferrous and non-ferrous metals

- Minimal post-casting machining required

🔗 Wikipedia: Investment Casting

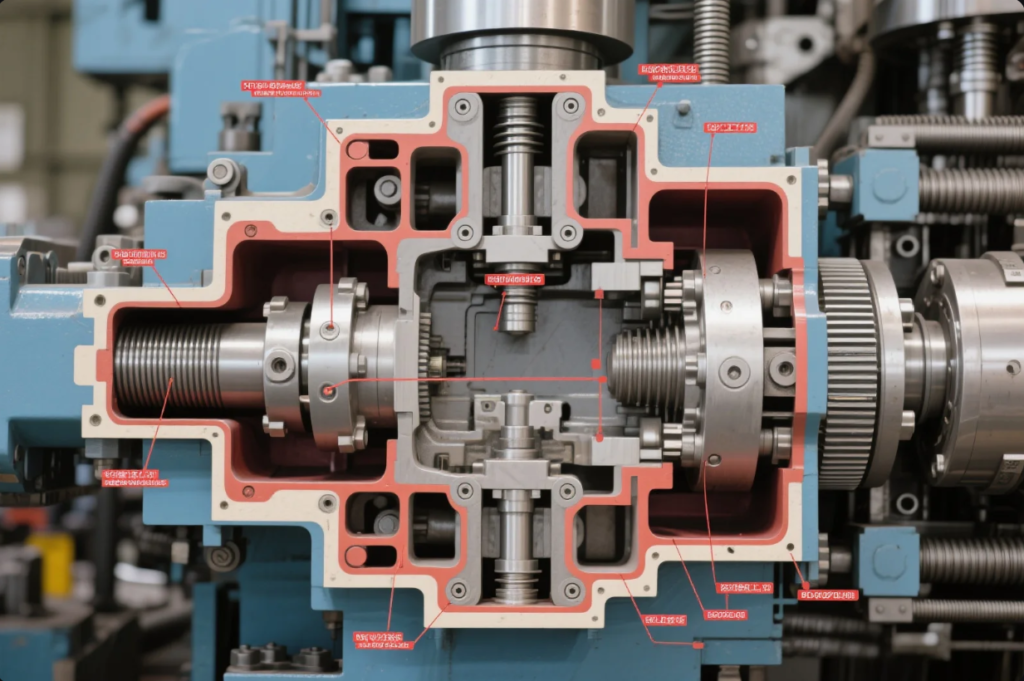

What is Die Casting?

Die casting involves forcing molten metal under high pressure into a steel mold (die). It is especially efficient for mass production of metal parts with high uniformity.

🔍 Features:

- Extremely fast production cycles

- High repeatability and tight tolerances

- Smooth surface finish (as-cast)

- Mainly used with non-ferrous metals like aluminum, zinc, and magnesium

🔗 TWI: Introduction to Die Casting

Key Differences Between Lost Wax and Die Casting

| Feature | Lost Wax Casting | Die Casting |

|---|---|---|

| Tolerance | ±0.05 mm | ±0.1–0.2 mm |

| Tooling Cost | Low to medium (wax molds) | High (steel dies) |

| Surface Finish | Good (Ra 3.2–6.3 µm) | Excellent (Ra 1.6–3.2 µm) |

| Production Volume | Low to medium | Medium to high |

| Part Complexity | Very high (no draft needed) | Limited (requires draft) |

| Material Flexibility | Ferrous and non-ferrous | Mostly non-ferrous |

| Mold Life | Single-use (ceramic shell) | High (thousands of cycles) |

Cost & Surface Finish Comparison

💰 Cost

- Lost Wax Casting: Cheaper for small batches due to simple wax tooling.

- Die Casting: More cost-effective in large production runs thanks to durable dies and rapid cycles.

✨ Surface Finish

- Die Casting: Superior as-cast finish, often eliminating the need for polishing or machining.

- Lost Wax Casting: Very good finish, especially suitable for detailed textures and tight tolerances.

🔗 MakeItFrom: Surface Finish Standards in Casting

Which Industries Use Each Method?

✈️ Aerospace: Lost Wax Casting

- High-performance alloys

- Engine parts, turbine blades, brackets

🔗 GE Aviation Investment Casting

🚗 Automotive: Die Casting

- Transmission housings, engine blocks

🔗 NADCA: North American Die Casting Association

🏥 Medical Devices

- Lost wax for surgical tools, orthopedic implants

📱 Consumer Electronics

- Die cast aluminum frames for laptops, smartphones

How to Choose the Right Casting Method

| Scenario | Recommended Method |

|---|---|

| Need very high precision | ✅ Lost Wax Casting |

| Large production volume | ✅ Die Casting |

| Ferrous metal components | ✅ Lost Wax |

| Parts require minimal surface machining | ✅ Die Casting |

| Complex geometry with undercuts | ✅ Lost Wax |

| Quick lead time with simple design | ✅ Die Casting |

💡 Tip: Use lost wax for prototypes and die casting for production scaling.

Comparing Mechanical Properties & Performance

| Property | Lost Wax Casting | Die Casting |

|---|---|---|

| Density | Higher | May have porosity |

| Strength | Excellent (ferrous metals) | Good (non-ferrous only) |

| Ductility | Better in steels | Limited |

| Surface Hardness | High (with treatment) | Moderate |

| Weldability | Yes | Limited |

🔗 AZoM: Heat Treatments for Cast Metals

Sustainability and Environmental Impact

| Factor | Lost Wax Casting | Die Casting |

|---|---|---|

| Energy Consumption | Medium | High |

| Recyclability | Wax reused | Dies reused 1000s times |

| Per Part Emissions | Higher | Lower in high-volume runs |

🔗 Reliance Foundry: Environmental Impact

Real-World Case Studies

🛫 Aerospace

Turbine blades for jet engines require precision casting for heat-resistant alloys and complex cooling channels.

🚗 Automotive

Transmission housings are mass-produced via die casting to achieve uniformity and speed.

🔗 Rolls-Royce Jet Engine Manufacturing

🔗 NADCA Automotive Case Studies

When to Combine Both Processes

- Prototype with lost wax, then scale with die casting

- Save tooling cost early, then reduce unit cost at scale

- Common in aerospace, electronics, robotics, and e-mobility

FAQs

Q1: Can die casting be used for stainless steel?

A: No. Die casting is limited to low-melting-point metals.

Q2: Which method is cheaper overall?

A: Lost wax for low volumes, die casting for mass production.

Q3: Is lost wax slower than die casting?

A: Yes, but it’s more flexible for custom and complex shapes.

Q4: What are the typical tolerances?

A: Lost wax: ±0.05 mm; Die casting: ±0.1–0.2 mm.

Contact Us

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

📍 Shandong Prime International Trade Co., Ltd.

Let our 20+ years of casting experience help you choose the right solution for your project.

© 2025 PrimeCustomParts.com – Excellence in Precision Metal Casting Worldwide