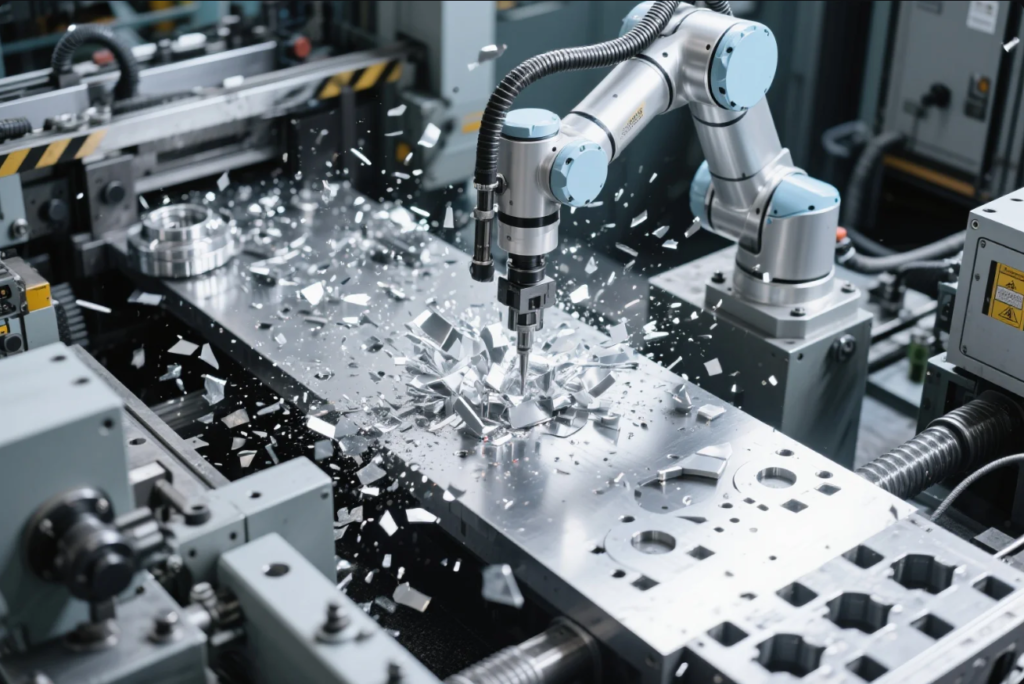

How to Ensure Quality Control in Custom Stamping Parts Manufacturing?

I\’ve experienced the frustration of receiving stamping parts that looked perfect but failed during assembly, causing production delays and significant financial losses.

Effective quality control in stamping parts manufacturing requires a comprehensive approach including incoming material inspection, in-process monitoring, statistical process control, and final verification using calibrated measurement tools. This systematic methodology prevents defects and ensures consistent performance.

Implementing robust quality control isn\’t just about avoiding defects—it\’s about ensuring consistency and reliability throughout your production process. Let\’s explore the essential elements of an effective quality control system.

What inspection methods are most effective for stamping parts?

I once received a shipment of stamping parts that passed visual inspection but had subtle dimensional issues that caused assembly failures, resulting in costly production delays.

The most effective inspection methods for stamping parts combine visual inspection, dimensional measurement, and material testing. Automated optical inspection systems can detect surface defects with 95% accuracy while coordinate measuring machines ensure dimensional precision to within 0.001mm.

The inspection methods you choose directly impact your ability to identify and prevent quality issues. Through my experience working with various manufacturers, I\’ve found that relying on a single inspection approach inevitably leaves blind spots that can result in costly defects reaching your production line.

Comparing Inspection Technologies for Stamping Parts

Different inspection technologies offer varying capabilities and are suited to different aspects of quality control.

| — | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Visual Inspection | Surface defects, obvious flaws | Subjective, misses internal issues | $ | Low | ||||||

| Coordinate Measuring Machine (CMM) | Precise dimensional verification | Slow, sampling required | $$$$ | High | ||||||

| Optical Measurement | Fast dimensional checks | Limited to visible features | $$$ | Moderate | ||||||

| Automated Optical Inspection (AOI) | High-volume surface inspection | Cannot detect internal defects | $$$ | Moderate | ||||||

| Material Testing | Verifying material properties | Destructive, sampling required | $$ | Moderate |

During my visit to Prime Custom Parts, I was impressed by their integrated inspection approach. They combine automated optical systems for 100% surface inspection with strategic CMM verification of critical dimensions, providing comprehensive quality assurance without excessive cost or time impact.

Developing an Effective Inspection Strategy

The most successful inspection strategies I\’ve implemented follow these key principles:

- Risk-based approach: Allocate inspection resources based on feature criticality and failure impact

- Multiple verification methods: Use complementary techniques to address different quality aspects

- Strategic sampling plans: Apply statistical methods to determine appropriate inspection frequency

- Clear acceptance criteria: Define specific, measurable standards for pass/fail decisions

- Documentation systems: Maintain records of inspection results for traceability and analysis

When working with a medical device manufacturer, we developed a tiered inspection strategy for their stamping parts. Critical safety features received 100% verification using precision measurement, while less critical dimensions were verified through statistical sampling. This balanced approach reduced inspection costs by 35% while maintaining zero defect escapes for critical features.

How can Statistical Process Control improve stamping part quality?

I once managed a project where we inspected every part but still experienced quality issues, until implementing SPC revealed subtle process drift that was causing intermittent failures.

Statistical Process Control (SPC) improves stamping part quality by monitoring process variables and identifying trends before they cause defects. By tracking key parameters and applying statistical analysis, manufacturers can maintain process stability and reduce variation by 40-60%.

Statistical Process Control represents a fundamental shift from detecting defects to preventing them. My experience implementing SPC systems has consistently shown that monitoring process parameters provides earlier warning of potential issues than inspecting finished parts, allowing for proactive adjustments that maintain quality.

Key SPC Tools for Stamping Operations

Several SPC tools are particularly valuable for monitoring and improving stamping processes.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Control Charts | Monitor process stability | Moderate | Early detection of process shifts | |||||

| Capability Studies | Assess process potential | Moderate | Identify improvement opportunities | |||||

| Pareto Analysis | Prioritize quality issues | Low | Focus resources on critical problems | |||||

| Fishbone Diagrams | Identify root causes | Low | Structured problem-solving approach | |||||

| Design of Experiments | Optimize process parameters | High | Systematic process improvement |

When consulting with a automotive parts manufacturer, I helped implement control charts for critical dimensions on their high-volume stamping line. Within three weeks, the charts revealed a cyclical variation pattern related to temperature fluctuations that had been causing intermittent quality issues for months. Addressing this root cause reduced defect rates by 78%.

Implementing Effective SPC in Stamping Operations

Based on my experience with multiple stamping operations, successful SPC implementation requires:

- Selecting appropriate control characteristics: Focus on parameters that directly impact part quality

- Establishing measurement systems: Ensure measurement processes are capable and consistent

- Determining control limits: Set statistically valid boundaries for acceptable variation

- Training operators: Develop skills to interpret charts and take appropriate actions

- Creating response plans: Define specific steps when processes approach control limits

During my collaboration with Prime Custom Parts, I observed their comprehensive SPC implementation across their stamping operations. Their approach includes real-time monitoring of press parameters and dimensional measurements, with automated alerts when processes begin to drift. This proactive system maintains their impressive 99.7% first-pass yield rate.

What role does material verification play in stamping part quality?

I once approved production based on a supplier\’s material certification, only to discover later that the actual material differed from the documentation, resulting in premature part failure.

Material verification is critical for stamping part quality, as material properties directly affect formability, strength, and performance. Effective verification includes certificate validation, regular testing, and traceability systems to ensure the correct materials are used throughout production.

Material verification often receives less attention than dimensional inspection, but my experience has shown that material issues can cause some of the most challenging quality problems. Unlike dimensional defects that are typically visible and immediate, material problems may not become apparent until parts fail in service, making them particularly costly and damaging to your reputation.

Essential Material Verification Methods

Several complementary approaches are necessary for comprehensive material verification.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Certificate Review | Reported material properties | Every shipment | Relies on supplier accuracy | |||||

| Positive Material Identification (PMI) | Material composition | Spot checks, critical applications | Surface analysis only | |||||

| Hardness Testing | Material strength | Regular sampling | Indirect measurement | |||||

| Tensile Testing | Mechanical properties | Periodic verification | Destructive, limited samples | |||||

| Metallographic Analysis | Microstructure | Problem investigation | Destructive, specialized equipment |

During my visit to a leading aerospace component manufacturer, I observed their multi-layered material verification system. Every material lot undergoes certificate verification and PMI testing before release to production, with periodic destructive testing to confirm mechanical properties. This rigorous approach has eliminated material-related failures in their critical applications.

Implementing Material Traceability Systems

Beyond verification testing, effective material control requires robust traceability systems:

- Lot identification: Maintain unique identifiers for all material lots

- Material segregation: Physically separate different materials and grades

- Process documentation: Record material information at each production stage

- Verification checkpoints: Implement verification at critical process transitions

- Record retention: Maintain material documentation for appropriate time periods

When working with Prime Custom Parts, I was impressed by their comprehensive material traceability system. Each material lot is assigned a unique identifier that follows the material through every production step, with verification checkpoints to prevent mix-ups. This system allows them to trace any part back to its original material certification, providing confidence in material quality.

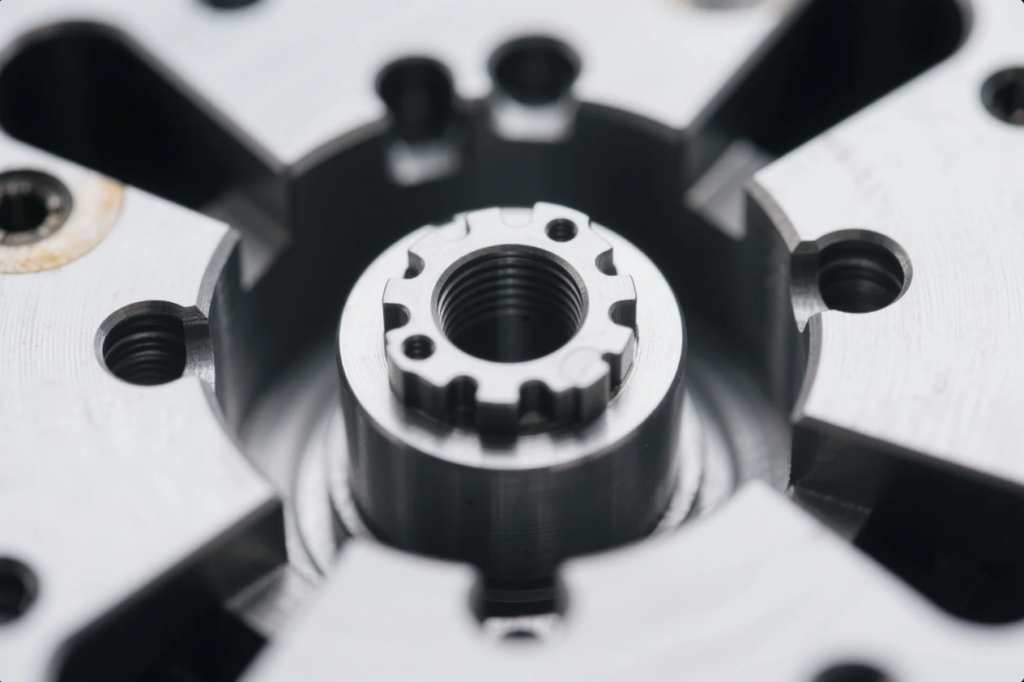

How important is tool and die maintenance for stamping quality?

I once experienced a sudden increase in defect rates that was traced to progressive tool wear that could have been prevented with proper maintenance protocols.

Tool and die maintenance is critical for stamping quality, as tool condition directly affects part dimensions, surface finish, and consistency. Preventive maintenance programs, wear monitoring, and scheduled refurbishment can extend tool life by 30-50% while maintaining consistent part quality.

The condition of stamping tools has a direct and immediate impact on part quality. Through my experience managing stamping operations, I\’ve found that tool maintenance is often reactive rather than preventive, leading to quality issues that could have been avoided with systematic maintenance approaches.

Developing Effective Tool Maintenance Programs

A comprehensive tool maintenance program addresses multiple aspects of tool performance and longevity.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Visual Inspection | Identify obvious wear or damage | Daily/Shift change | Prevents catastrophic failures | |||||

| Dimensional Verification | Detect gradual wear | Weekly/Lot change | Maintains part dimensions | |||||

| Preventive Refurbishment | Address wear before failure | Based on stroke count | Prevents quality degradation | |||||

| Cleaning and Lubrication | Maintain optimal performance | Daily/Shift change | Ensures consistent operation | |||||

| Complete Reconditioning | Restore to original specifications | Based on condition | Resets tool performance |

During my consultation with a consumer electronics manufacturer, we implemented a stroke-count-based maintenance program for their high-volume stamping tools. By scheduling preventive maintenance based on documented wear patterns, they reduced unplanned tool failures by 85% and extended average tool life by 42%.

Advanced Tool Monitoring Techniques

Beyond basic maintenance schedules, leading manufacturers implement advanced monitoring to optimize tool performance:

- In-die sensors: Detect force variations that indicate wear or damage

- Vision systems: Monitor tool condition during operation

- Performance trending: Track quality metrics to identify gradual degradation

- Predictive analytics: Use data patterns to anticipate maintenance needs

- Standardized documentation: Maintain detailed records of tool history and performance

When visiting Prime Custom Parts, I observed their sophisticated tool management system that includes sensor monitoring on critical tools and comprehensive performance tracking. This approach allows them to optimize maintenance timing—performing it early enough to prevent quality issues but late enough to maximize tool utilization and cost-effectiveness.

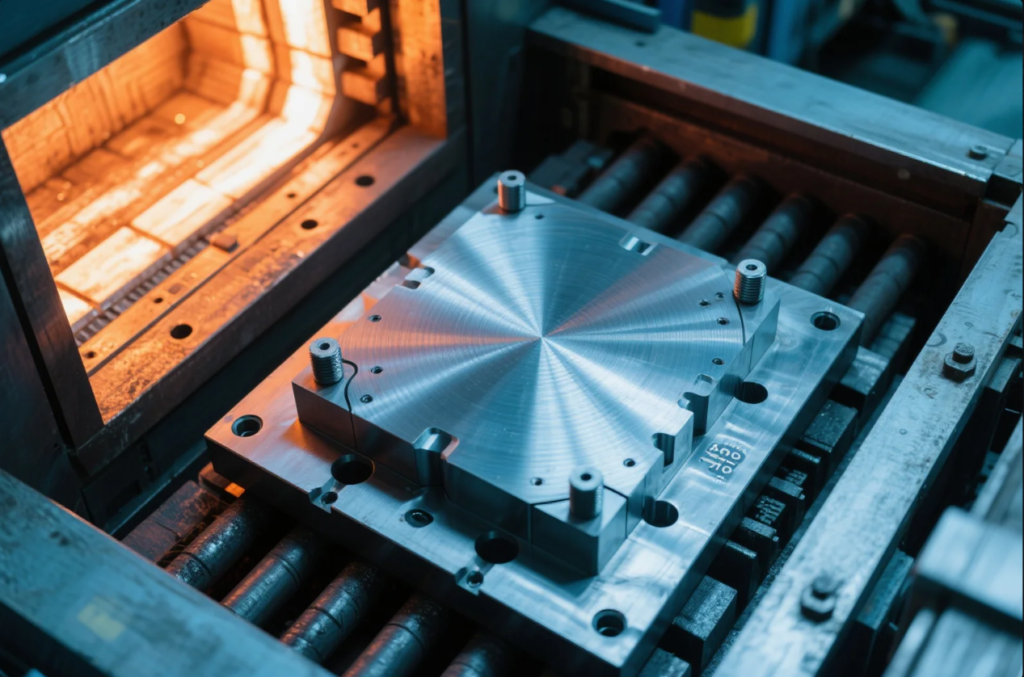

How can process validation improve stamping part quality?

I once assumed a well-designed process would consistently produce good parts, until validation testing revealed that normal process variation caused occasional defects in complex geometries.

Process validation improves stamping part quality by systematically verifying that processes consistently produce parts meeting all requirements. Through installation qualification, operational qualification, and performance qualification, manufacturers can identify and address variation sources before production.

Process validation represents a proactive approach to quality that goes beyond traditional inspection methods. My experience implementing validation protocols has shown that thoroughly understanding process capabilities and limitations before production begins dramatically reduces quality issues during actual production runs.

The Three Phases of Effective Process Validation

A comprehensive validation approach includes three distinct but interconnected phases.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Installation Qualification (IQ) | Equipment capability | Verify specifications, calibration | Ensures proper equipment foundation | |||||

| Operational Qualification (OQ) | Process parameter ranges | Test operating limits, establish controls | Defines robust operating windows | |||||

| Performance Qualification (PQ) | Consistent performance | Extended production runs, statistical analysis | Confirms real-world capability |

When helping a medical device manufacturer establish their stamping operation, we implemented a rigorous validation protocol for each new tool and process. During the OQ phase of a particularly complex part, we discovered that the process was highly sensitive to material thickness variations within the specified tolerance range. By tightening our material specifications, we eliminated this variation source before beginning production.

Process Validation Best Practices

Based on my experience implementing validation programs across multiple industries, several key practices contribute to successful outcomes:

- Risk-based approach: Focus validation efforts on elements with highest quality impact

- Worst-case testing: Validate performance at the extremes of acceptable parameters

- Statistical rigor: Apply appropriate sample sizes and analytical methods

- Documentation systems: Maintain comprehensive records of all validation activities

- Periodic revalidation: Verify continued process capability after changes or over time

During my collaboration with Prime Custom Parts, I was impressed by their systematic approach to process validation. Each new part undergoes a structured validation protocol scaled according to complexity and criticality. This front-loaded quality approach has enabled them to achieve first-time success rates exceeding 95% for new part introductions.

What quality documentation systems are essential for stamping operations?

I once struggled to resolve a recurring quality issue because the manufacturer lacked documentation of previous occurrences and resolution attempts, forcing us to repeatedly investigate the same root causes.

Essential quality documentation for stamping operations includes control plans, inspection procedures, process specifications, corrective action records, and traceability systems. These documents create a quality framework that ensures consistency, enables continuous improvement, and provides accountability.

Effective documentation forms the backbone of any quality system, transforming individual knowledge into organizational capability. Through my experience implementing quality systems, I\’ve found that well-designed documentation creates consistency across shifts, operators, and time periods while providing the data foundation needed for continuous improvement.

Core Quality Documentation for Stamping Operations

Several key documents form the foundation of an effective quality system for stamping operations.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Control Plan | Define quality activities | Inspection points, methods, frequency | Ensures comprehensive quality coverage | |||||

| Work Instructions | Guide process execution | Step-by-step procedures, acceptance criteria | Creates consistency across operators | |||||

| Inspection Procedures | Standardize verification | Measurement methods, equipment, sample sizes | Ensures reliable quality assessment | |||||

| Corrective Action Records | Document problem resolution | Issue description, root cause, verification | Prevents recurrence of issues | |||||

| Material Certifications | Verify material properties | Composition, mechanical properties, source | Ensures appropriate material use |

When consulting with an automotive parts supplier, we implemented a structured documentation system for their stamping operations. Ensure Quality Control in Custom Stamping Parts Manufacturing. Within six months, this system revealed patterns in quality issues that had previously seemed random, allowing targeted improvements that reduced defect rates by 62%.

Leveraging Digital Documentation Systems

Modern quality documentation has evolved beyond paper records to integrated digital systems that provide significant advantages:

- Real-time data access: Immediate availability of current procedures and specifications

- Automated workflows: Structured processes for document approval and implementation

- Integrated data analysis: Connection between quality records and improvement activities

- Enhanced traceability: Digital links between related quality information

- Simplified compliance: Streamlined auditing and regulatory reporting

During my visit to Prime Custom Parts, I observed their comprehensive digital quality system that integrates documentation, inspection data, and process monitoring. Ensure Quality Control in Custom Stamping Parts Manufacturing. This system provides real-time quality visibility across their operations and automatically flags potential issues for investigation, enabling proactive quality management rather than reactive problem-solving.

How can employee training impact stamping part quality?

I once implemented advanced inspection equipment that failed to improve quality because operators lacked proper training on interpretation and response to the measurement data.

Employee training significantly impacts stamping part quality by ensuring proper execution of procedures, accurate interpretation of quality data, and appropriate response to process variations. Comprehensive training programs covering technical skills, quality awareness, and problem-solving can reduce defect rates by 40-70%.

The human element remains critical in stamping quality despite increasing automation. My experience implementing quality improvements has consistently shown that even the best-designed processes and most advanced equipment cannot compensate for inadequate operator training and understanding.

Essential Training Elements for Stamping Quality

A comprehensive training program addresses multiple knowledge and skill areas that impact quality.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Process Knowledge | Equipment operation, material behavior | Hands-on, demonstration | Proper execution of procedures | |||||

| Quality Awareness | Defect recognition, quality standards | Visual aids, examples | Early detection of issues | |||||

| Measurement Skills | Gauge usage, data interpretation | Practical exercises, certification | Accurate quality assessment | |||||

| Problem-Solving | Root cause analysis, corrective action | Case studies, mentoring | Effective issue resolution | |||||

| Continuous Improvement | Data analysis, process optimization | Project-based learning | Ongoing quality enhancement |

When working with a consumer electronics manufacturer, we implemented a tiered training program for their stamping operators. The program included certification requirements for different equipment and processes, with regular skill assessments and refresher training. Within one year, operator-related quality issues decreased by 58%, while process improvement suggestions from operators increased by 215%.

Creating a Quality-Focused Culture Through Training

Beyond specific skills, effective training programs build a culture that prioritizes quality:

- Quality responsibility: Emphasizing each person\’s role in ensuring product quality

- Decision authority: Empowering operators to stop processes when quality issues arise

- Continuous learning: Encouraging ongoing skill development and knowledge sharing

- Recognition systems: Acknowledging and rewarding quality contributions

- Cross-functional understanding: Building awareness of how quality impacts other areas

During my collaboration with Prime Custom Parts, I was impressed by their comprehensive training approach that extends beyond basic skills to include quality philosophy and customer impact awareness. Ensure Quality Control in Custom Stamping Parts Manufacturing. Their operators understand not just how to make parts, but why specific quality requirements matter to end users, creating personal investment in quality outcomes.

How can supplier quality management affect stamping part quality?

I once traced persistent quality issues to inconsistent raw materials, discovering that our supplier had changed their process without notification, affecting the material\’s formability.

Supplier quality management directly impacts stamping part quality by ensuring consistent raw materials and components. Effective supplier programs including qualification, performance monitoring, and collaborative improvement can reduce material-related defects by 50-80%.

The quality of your stamping parts can never exceed the quality of your input materials. Through my experience managing supply chains, I\’ve found that many quality issues attributed to manufacturing processes actually originate with material variations that could have been prevented through effective supplier management.

Key Elements of Effective Supplier Quality Management

A comprehensive supplier quality program addresses multiple aspects of the supplier relationship.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Supplier Qualification | Verify capability before purchasing | Audits, capability assessment | Prevents selection of inadequate suppliers | |||||

| Performance Monitoring | Track ongoing quality levels | Metrics, scorecards | Identifies degradation trends early | |||||

| Quality Requirements | Clearly define expectations | Specifications, standards | Ensures alignment on quality criteria | |||||

| Corrective Action Process | Address quality issues | Structured problem-solving | Prevents recurrence of defects | |||||

| Continuous Improvement | Enhance capabilities over time | Joint projects, training | Drives ongoing quality advancement |

When helping an aerospace component manufacturer improve their stamping quality, we implemented a structured supplier qualification process for critical materials. Ensure Quality Control in Custom Stamping Parts Manufacturing. This process included on-site capability assessments and trial production runs before approving new suppliers. The resulting improvement in material consistency reduced in-process rejections by 64% and virtually eliminated material-related field failures.

Building Collaborative Supplier Relationships

Beyond formal programs, the most effective supplier quality management approaches build collaborative relationships:

- Technical exchange: Sharing expertise to solve common challenges

- Early involvement: Including suppliers in design and process development

- Transparent communication: Providing clear feedback on performance issues

- Mutual improvement goals: Establishing shared quality objectives

- Long-term partnerships: Creating stability that enables investment in quality

During my visit to Prime Custom Parts, I observed their approach to supplier management that emphasizes partnership over transactional relationships. They maintain long-term relationships with key material suppliers, conducting regular technical exchanges and collaborative improvement projects. This approach has enabled them to achieve material quality levels that support their zero-defect objectives for critical applications.

How can continuous improvement methodologies enhance stamping part quality?

I once managed a stamping operation that maintained acceptable quality but struggled with persistent minor issues until implementing structured improvement methodologies that transformed performance.

Continuous improvement methodologies enhance stamping part quality by systematically identifying and addressing quality limitations. Approaches like Six Sigma, Lean Manufacturing, and Total Quality Management provide structured frameworks that typically reduce defect rates by 50-90% while improving efficiency.

Continuous improvement represents the difference between acceptable quality and exceptional quality. Ensure Quality Control in Custom Stamping Parts Manufacturing. My experience implementing improvement methodologies across various manufacturing operations has shown that structured approaches consistently achieve results that far exceed ad-hoc improvement efforts.

Comparing Improvement Methodologies for Stamping Operations

Different improvement methodologies offer varying approaches and strengths for stamping quality enhancement.

| — | ||||||||

|---|---|---|---|---|---|---|---|---|

| Six Sigma | Reducing variation | Statistical analysis, DMAIC process | Complex quality problems with multiple variables | |||||

| Lean Manufacturing | Eliminating waste | Value stream mapping, 5S, visual management | Efficiency improvements with quality benefits | |||||

| Total Quality Management | Comprehensive quality culture | Cross-functional teams, customer focus | Organization-wide quality transformation | |||||

| Theory of Constraints | Identifying and addressing bottlenecks | Constraint analysis, buffer management | Throughput improvements while maintaining quality | |||||

| Kaizen | Incremental daily improvement | Quick improvement cycles, operator involvement | Continuous small-scale quality enhancements |

When consulting with an automotive parts manufacturer, we implemented a Six Sigma program focused on their most challenging stamping quality issues. Ensure Quality Control in Custom Stamping Parts Manufacturing. By applying the DMAIC methodology (Define, Measure, Analyze, Improve, Control) to a persistent burr problem, the team reduced defect rates from 3.2% to 0.08% while simultaneously increasing production speed by 12%.

Critical Success Factors for Improvement Initiatives

Based on my experience leading improvement programs, several factors determine the success of quality enhancement efforts:

- Leadership commitment: Visible support and resource allocation from management

- Data-driven decisions: Basing improvements on analysis rather than opinions

- Cross-functional involvement: Including perspectives from all relevant areas

- Structured methodology: Following proven improvement frameworks

- Sustainability focus: Implementing controls to maintain improvements

Ensure Quality Control in Custom Stamping Parts Manufacturing.During my collaboration with Prime Custom Parts, I observed their integrated improvement system that combines elements from multiple methodologies. Their approach includes daily team-based improvements, structured project teams for complex issues, and a comprehensive measurement system that guides improvement priorities. This multi-faceted system has enabled them to achieve year-over-year quality improvements averaging 22% annually.

Contact Us

📧 Email us: [email protected]🌐 Visit: https://primecustomparts.com

Get a free quote, custom tool configuration, and fast delivery worldwide. Every order comes with setup support.

Conclusion

Ensuring quality control in custom stamping parts manufacturing requires a comprehensive approach that addresses all aspects of the production process. By implementing effective inspection methods, statistical process control, material verification, tool maintenance, process validation, documentation systems, employee training, supplier management, and continuous improvement methodologies, manufacturers can achieve the consistent quality that today\’s demanding applications require.