Rivets & Specialty Fasteners: When Standard Won’t Do

Standard bolts can’t always do the job.

Rivets and specialty fasteners offer permanent, secure, and vibration-resistant joining for thin, fragile, or inaccessible materials. Learn when and why to use them.

Sometimes, torque-based fasteners fail. In such cases, rivets and custom inserts step up.

Introduction

Not every assembly can handle threaded fasteners. In high-vibration zones or when only one side is accessible, rivets and self-clinching fasteners provide unmatched security. At Prime, we support global clients with specialty fastening solutions for thin materials, electronics, aviation panels, and more.

This guide explains the when, why, and how of rivet selection—backed by industry standards, case studies, and design guidance.

Solid vs Blind (Pop) Rivets: Use Cases

Solid rivets are strong but hard to install. Pop rivets install fast with access from one side.

Solid rivets deliver structural strength. Blind rivets work where rear access isn’t possible. Each has ideal environments.

| Type | Strength | Installation Access | Typical Use |

|---|---|---|---|

| Solid Rivet | Very High | Both sides required | Aircraft wings, engine parts |

| Blind (Pop) Rivet | Moderate | One side only | Electronics, enclosures |

When to Use Solid Rivets: Load-critical areas like airframes and suspension.

When to Use Pop Rivets: Inaccessible back panels like wall mounts and electronics housings.

Helpful links:

- Aircraft Tool Supply – Solid Rivet Installation

- Hanson Rivet – How Pop Rivets Work

- Fastener Mart – Blind Rivet Overview

Tubular Rivets: Advantages in Sheet Metal

Tubular rivets are lightweight and formable—ideal for high-speed assembly and thin materials.

Tubular rivets provide strong mechanical lock with minimal distortion. Perfect for sheet metal, HVAC, and consumer electronics.

| Type | Hole Type | Strength | Ideal For |

|---|---|---|---|

| Semi-Tubular Rivet | Through-hole | Moderate | Luggage, ductwork, furniture frames |

| Full-Tubular Rivet | Through-hole | Light Duty | Toys, lighting enclosures |

Advantages:

- No threading = faster install

- Low noise in robotic settings

- Secure locking under vibration

At Prime, we offer custom head forms and metal types, including brass, stainless, and aluminum.

Resources:

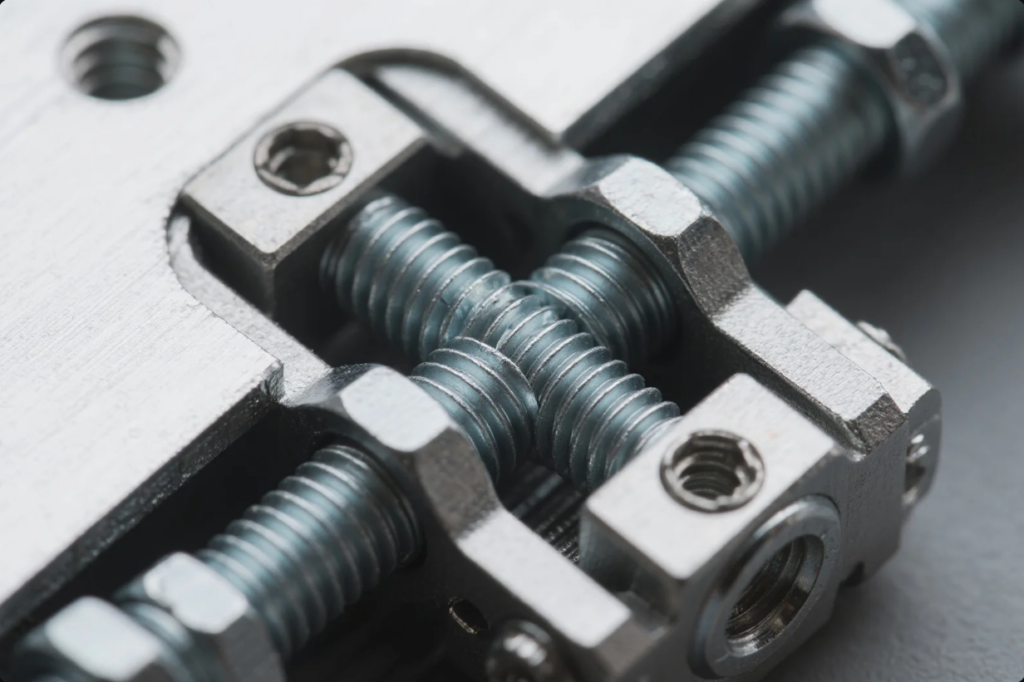

Self‑Clinching Fasteners for Thin Materials

Threaded fasteners often strip thin sheet. Self-clinching fasteners eliminate that issue.

These fasteners embed into sheet metal under force and offer secure threads without tapping or welding.

| Fastener Type | Function | Applications |

|---|---|---|

| Clinch Nuts | Threaded access | Electronics, telecom panels |

| Clinch Studs | Fixed mount posts | Control boxes, medical equipment |

| Standoffs | Spacer/insulator | PCB mount, LED modules |

Advantages:

- Works in panels as thin as 0.5 mm

- High torque/push-out strength

- Fast, repeatable installation

Prime’s line includes M2–M10 clinch nuts, studs, and standoffs, compatible with steel, aluminum, copper panels.

Learn more:

- PennEngineering Fastener Design Info

- Accuride – Benefits of Clinching

- Nord-Lock Sheet Fastening Guide

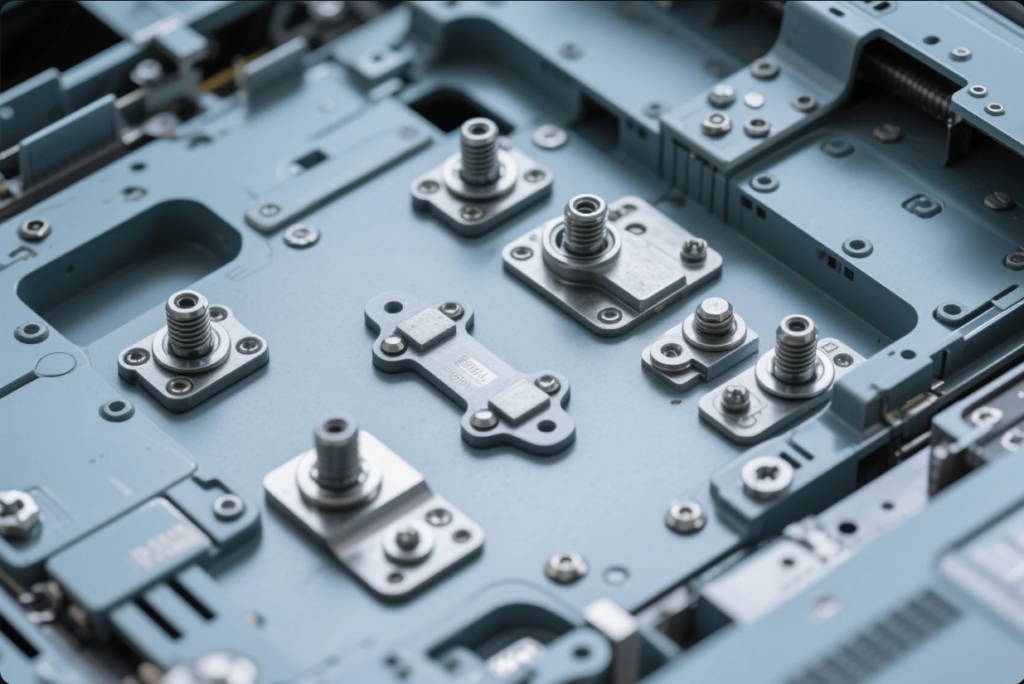

Application Examples: Electronics & Aerospace

Miniaturization and vibration define the need for rivets and clinch fasteners in modern design.

In electronics and aerospace, these fasteners solve clearance, access, and strength challenges.

Electronics Examples:

- Pop rivets in TV mounts

- Clinch studs for motherboard trays

- Micro standoffs for sensor insulation

Aerospace Examples:

- Solid rivets in fuselage panels

- Titanium rivets in turbines

- Self-clinching wire routing studs

Case: Prime supplied a UK aerospace client with tri-fold blind rivets for curved air ducts. Parts passed 1000-hour vibration testing with zero failures.

Explore more:

FAQs

1. Can pop rivets replace bolts?

No. Pop rivets are non-removable and used for thin materials or light loads only.

2. What’s the strongest type of rivet?

Solid rivets. Especially when made from high-strength aluminum or titanium.

3. Are clinch fasteners permanent?

Yes, they are designed to be permanent but allow screw-in/out of attached parts.

4. Do rivets need special tools?

Yes. Pop rivets require rivet guns. Clinch fasteners need a press or arbor.

5. What industries use the most rivets?

Aerospace, electronics, automotive, HVAC, and appliance manufacturing.

Conclusion & Contact

When bolts and screws can’t solve your assembly challenges, rivet and specialty fastening solutions step in. Whether you’re manufacturing drones, satellite boxes, or enclosure panels, Prime is your reliable source for ISO-compliant, custom-designed fasteners.

📩 Contact us today for:

- Blind, solid, tubular, or clinch fasteners

- Material and finish recommendations

- 2D/3D drawings and full test documentation

- Quick turnarounds and global delivery

🌐 Website: https://primecustomparts.com

✉️ Email: [email protected]

Secure your next design with Prime—when standard won’t do.