Selecting the Right Alloy for Metal Casting Applications

Choosing the right alloy is a critical step in the metal casting process. The selected material affects not only the strength and durability of the final part but also factors such as cost, machinability, corrosion resistance, and weight. Whether you’re casting automotive components, electronic housings, or structural supports, this guide will help you evaluate the performance trade-offs among popular casting alloys—aluminum, steel, cast iron, zinc, magnesium, and copper—and make informed decisions based on your application and budget.

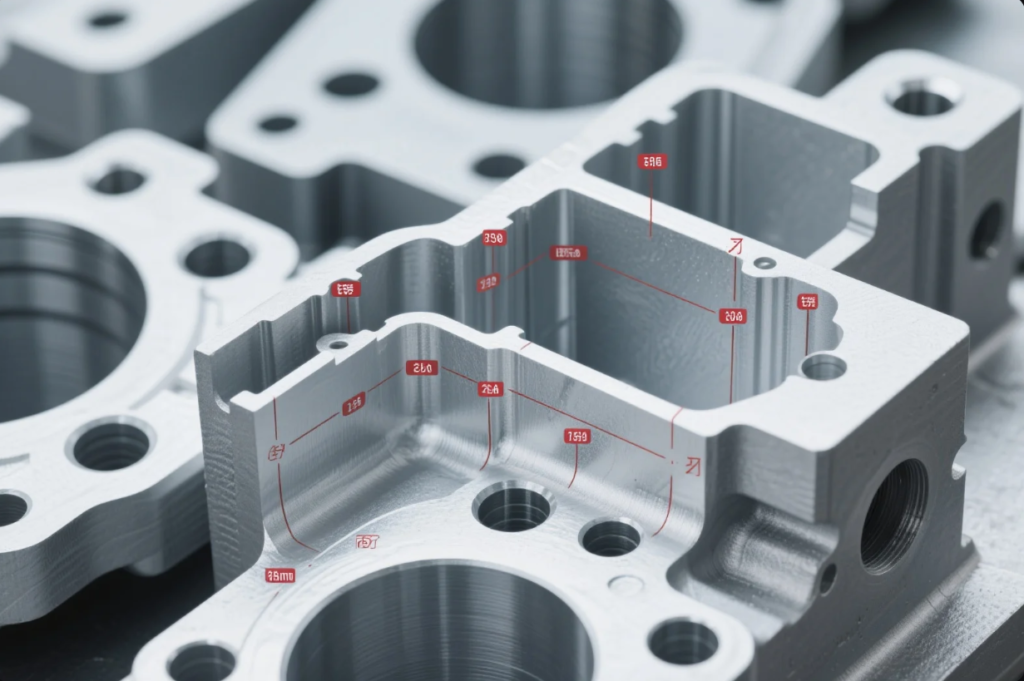

Aluminum vs Steel vs Cast Iron: Core Differences

🪶 Aluminum Alloys

- Lightweight, corrosion-resistant, and thermally conductive

- Used in aerospace, automotive, and consumer electronics

- Excellent for complex die cast shapes with thin walls

- Machinable, but softer than steel or iron

🔗 AZoM: Properties of Cast Aluminum Alloys

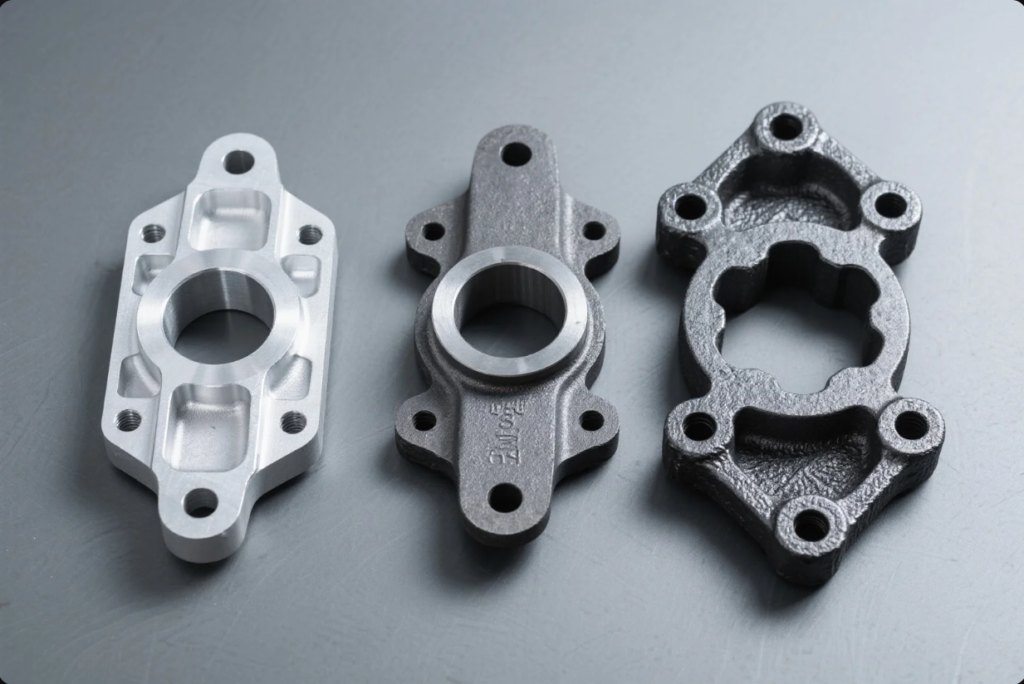

🔩 Steel Alloys (Carbon, Alloy, Stainless)

- High strength, toughness, and fatigue resistance

- Suitable for structural and high-load applications

- Higher melting point than aluminum, which affects casting method choice (often sand or investment casting)

- Corrosion resistance varies by alloy type

🔧 Cast Iron (Gray, Ductile, Malleable)

- Excellent damping capacity, high wear resistance

- Common in engine blocks, pumps, machine bases

- Brittle compared to steel, but lower cost

- Great for large, rigid parts needing vibration absorption

Zinc and Magnesium Alloys: Lightweight vs Strength

⚖️ Zinc Alloys

- Extremely precise casting capabilities

- Excellent dimensional control and thin-wall casting

- Lower melting point (approx. 420°C) – energy efficient

- Corrosion resistant, but not suitable for high temperatures

- Used in locks, hinges, connectors, electronics housings

🔗 DieCasting.org: Zinc Die Casting Applications

✈️ Magnesium Alloys

- The lightest structural metal available

- High strength-to-weight ratio

- Excellent for aerospace, auto dashboards, electronics

- Requires special handling due to oxidation risks during melting

- Less corrosion resistant unless coated

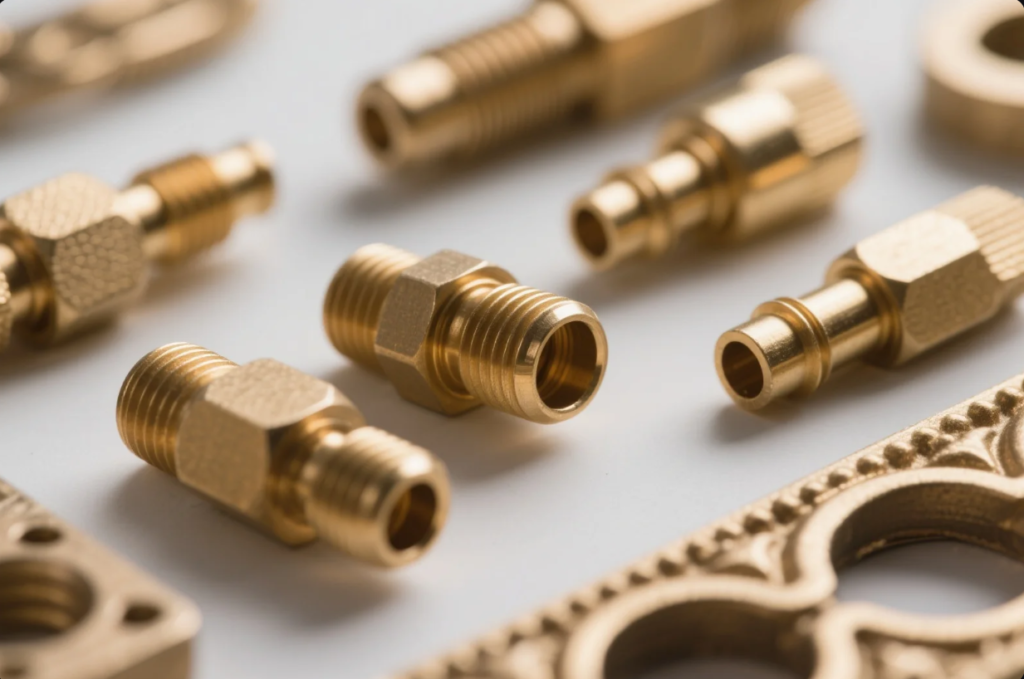

Copper Alloys: Electrical Conductivity & Corrosion Resistance

🔌 Copper & Its Alloys (Bronze, Brass)

- Excellent electrical and thermal conductivity

- Natural resistance to corrosion, even in marine environments

- Easy to cast into complex shapes

- Used in electrical components, plumbing, decorative items, and bushings

💡 Notable Subtypes:

- Bronze (Cu + Sn): Tough and corrosion-resistant, especially for marine and industrial use

- Brass (Cu + Zn): Good for precision parts, fittings, instruments

🔗 Matmatch: Overview of Copper Alloys

How to Choose Based on Application & Budget

| Requirement | Recommended Alloy |

|---|---|

| Low cost & vibration damping | 🟠 Cast Iron |

| Lightweight with good strength | 🟣 Aluminum or Magnesium |

| High-strength & wear resistance | 🔵 Steel |

| Electrical/thermal conductivity | 🟡 Copper or Brass |

| High-volume, low-temp casting | 🟢 Zinc |

| Corrosion resistance | 🔴 Stainless steel or Bronze |

🔍 Budget Considerations

| Material | Relative Cost | Machining | Surface Finish | Energy to Cast |

|---|---|---|---|---|

| Aluminum | $$ | Easy | Good | Low |

| Steel | $$$ | Moderate | Fair | High |

| Cast Iron | $ | Difficult | Rough | Medium |

| Zinc | $ | Easy | Excellent | Very Low |

| Magnesium | $$$ | Easy | Good | Medium |

| Copper Alloys | $$$$ | Easy | Excellent | High |

FAQs

Q1: What is the best alloy for high-heat environments?

A: Steel and certain nickel-based alloys are most heat resistant.

Q2: Which metal offers the best strength-to-weight ratio?

A: Magnesium alloys, followed by aluminum.

Q3: Are zinc parts durable?

A: Yes, especially in indoor or controlled environments, though not for high heat.

Q4: Can copper alloys be used for structural parts?

A: Rarely. They’re typically used for conductivity or corrosion resistance.

Q5: What’s the most cost-effective option for general industrial use?

A: Cast iron for rigidity or aluminum for versatility and light weight.

Contact Us

Still not sure which alloy is right for your application?

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

🏭 Shandong Prime International Trade Co., Ltd. — Providing custom alloy solutions in castings for over 20 years

© 2025 PrimeCustomParts.com — Helping You Cast With Confidence