Should a Beginner Use a MIG or Arc Welder?

Choosing the wrong welding method as a beginner leads to poor welds and wasted time.

MIG welding is generally easier for beginners due to its simplicity, cleaner results, and shorter learning curve.

Let’s break down which welding method suits your starting point best—and how to avoid frustration.

Is a MIG or ARC welder better for beginners?

Most beginners struggle with stick (arc) welding’s high heat and spatter.

MIG welding offers easier control, cleaner results, and faster learning for beginners.

Why MIG wins for welding beginners

In my early welding days, I started with stick welding. Honestly, I wish I had gone with MIG. The reasons are clear:

- MIG has automatic wire feeding, so no need to manage rod angle or arc length.

- The process is cleaner—less smoke, less slag.

- It’s forgiving on thinner materials, which are easier for starters.

Table: MIG vs. ARC Welding for Beginners

| Feature | MIG Welding | Stick (ARC) Welding |

|---|---|---|

| Ease of Use | Very beginner-friendly | Steeper learning curve |

| Cleanliness | Minimal cleanup | Heavy slag and spatter |

| Material Suitability | Great for thin metals | Better for thick/rusty metal |

| Equipment Cost | Higher upfront | Lower initial cost |

| Control & Precision | High | Moderate |

At Prime, we often recommend MIG welding setups to newer clients looking to train their own teams or do basic metal fabrication in-house.

What type of welder should a beginner start with?

Many buyers choose complex machines too early and end up frustrated.

A beginner should start with a MIG welder using solid wire and shielding gas.

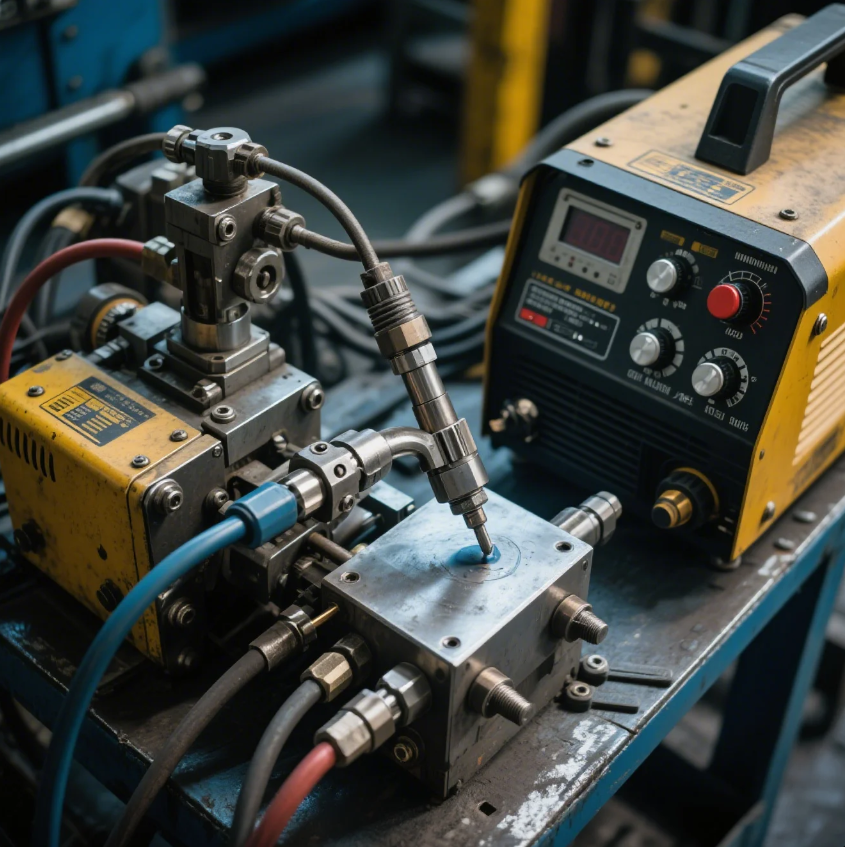

Best beginner welder: Features to look for

Based on years of client feedback and my own experience training entry-level fabricators, here’s what I always suggest:

Key beginner MIG welder features:

- Single-phase power supply (easy to use at home or workshop)

- Wire feed speed control

- Voltage adjustment knobs

- Optional flux-core compatibility for outdoor work

And while flux-core MIG doesn’t need a gas tank, it does produce more smoke. For truly clean, smooth welds, shielded gas MIG welding is still the better choice.

Table: Welder Selection Guide for Beginners

| Welder Type | Ideal Use Case | Complexity | Required Equipment |

|---|---|---|---|

| MIG (with gas) | Sheet metal, mild steel | Low | Gas + solid wire |

| Flux-Core MIG | Outdoor, windy conditions | Medium | Flux wire only |

| Stick (ARC) | Farm tools, repairs | High | Electrodes + helmet |

| TIG | Artistic/precision welds | Very High | Foot pedal + filler rod |

Prime supplies OEM welding parts, and we often consult customers on setting up entry-level MIG weld stations using our pre-welded components to simplify operations.

Is MIG welding easy for beginners?

MIG welding feels more like “point and shoot” compared to stick welding.

Yes, MIG welding is the easiest welding type for beginners to learn.

How MIG makes learning to weld simple

When I teach clients’ teams basic welding, I almost always start with MIG. Why? Because it builds confidence quickly.

What makes MIG so approachable:

- The gun handle works like a glue gun—intuitive to use.

- Wire feed control adjusts the speed, making it easier to handle the bead.

- No need to keep replacing rods or restarting the arc.

- Minimal slag means you can see your results clearly and adjust as you go.

Table: MIG Welding Learning Timeline (Beginner Level)

| Skill | Average Time to Learn | Notes |

|---|---|---|

| Holding correct angle | 1–2 sessions | MIG gun is ergonomic |

| Speed control | 3–4 sessions | Depends on feed setting |

| Consistent bead size | 4–5 sessions | Easier than TIG or Stick |

| Weld penetration | 5–6 sessions | Learn by practicing joints |

At Prime, we also offer CNC parts and pre-cut blanks for practice. Many buyers order these to train their staff quickly with MIG setups.

What is the hardest welding to learn?

TIG welding is the most challenging due to coordination and precision requirements.

TIG welding is the hardest welding method to master for beginners.

Why TIG is hard and when it’s worth the effort

TIG stands for Tungsten Inert Gas welding. Unlike MIG or stick, you have to control the torch with one hand, the filler rod with the other, and the power with your foot.

It’s like playing the drums while doing calligraphy.

Challenges of TIG welding:

- Extremely slow pace

- Very clean, prepped surfaces required

- Foot-pedal amperage control

- Precise filler metal feed and arc gap control

I’ve seen even experienced welders take months to get consistent TIG welds. That’s why at Prime, we rely on certified TIG operators and robotic welders for aerospace-grade parts.

Table: Welding Method Difficulty Comparison

| Welding Method | Difficulty | Typical Learning Time | Common Applications |

|---|---|---|---|

| MIG | Low | 1–2 weeks | Fabrication, auto panels |

| Stick (ARC) | Medium | 2–4 weeks | Repairs, construction |

| TIG | Very High | 2–6 months | Aerospace, medical devices |

| FCAW | Medium | 2–3 weeks | Shipbuilding, outdoors |

We regularly produce ISO-certified TIG-welded parts for customers in Europe and North America who demand ultra-precise welds for critical-use components.

Conclusion

MIG welding is easiest for beginners—clean, fast, and beginner-friendly—ideal for anyone starting their welding journey.

Want to simplify your welding workflow or get pre-welded industrial parts?

Contact Prime today for free consultation, quote, and samples.

Our team delivers fast, certified components trusted by global buyers.

Start welding smarter—reach out now!