Smart Manufacturing for Plastic Parts: AI, Automation, and Quality Control?

In plastic part production, inefficiencies lead to defects, delays, and cost overruns.

Smart manufacturing—leveraging IoT, AI, automated tooling, and lights-out operations—brings consistency, speed, and traceability to injection molding. Implementation delivers real-time quality control, optimized processes, and scalable output.

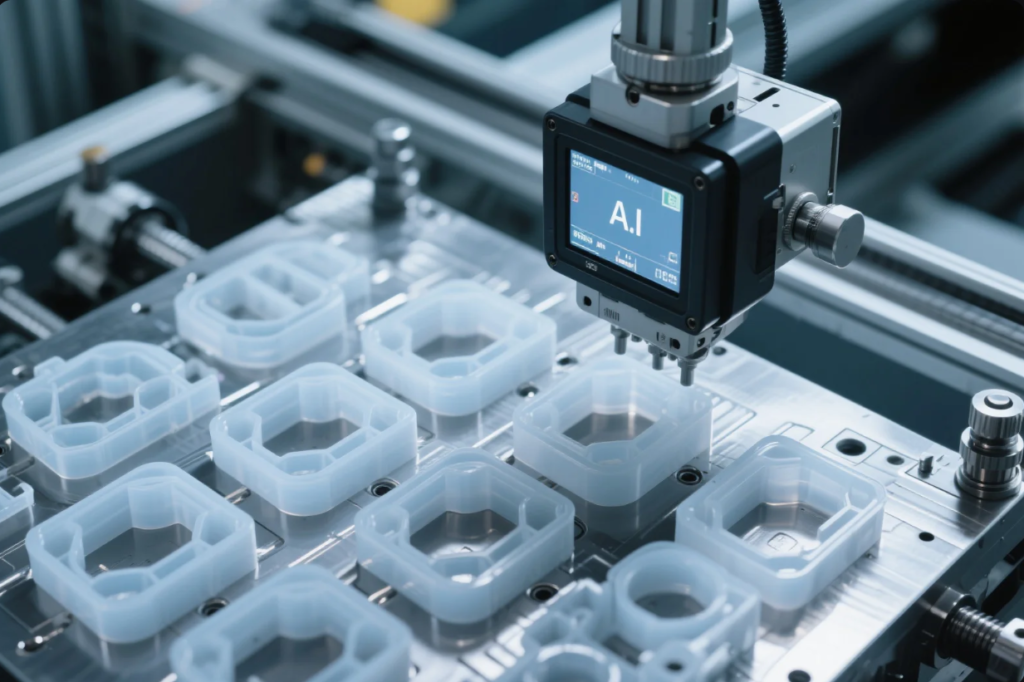

Industry 4.0: IoT, OPC-UA, and MES redefine production

Manufacturing without connectivity is slow and inefficient.

Industry 4.0 uses IoT sensors, OPC-UA protocols, and MES systems for integrated, real-time data flow and factory control.

Understanding the IoT Layer

- IoT sensors (temperature, pressure, humidity) capture continuous data streams. Companies like Cypress Semiconductor and Bosch IoT offer hardened industrial sensors.

- Edge devices process data locally to avoid latency and network overload, as outlined in edge computing architectures.

- Communication protocols like OPC-UA enable secure, standardized device integration.

MES Drives Traceability

- Systems like Siemens Opcenter and Rockwell FactoryTalk handle batch management, electronic work orders, and process adjustments.

- Prime uses MES to log cycle counts, machine status, material lots, and reject cause codes—creating a complete audit trail.

Benefits include:

- 15% scrap reduction via anomaly alerts

- 20% faster uptime recovery through guided workflows

- Full traceability needed for ISO 9001 and automotive APQP compliance (IATF 16949)

“Connecting machines to MES turns data into continuous improvements”—source: McKinsey Industry 4.0 insights.

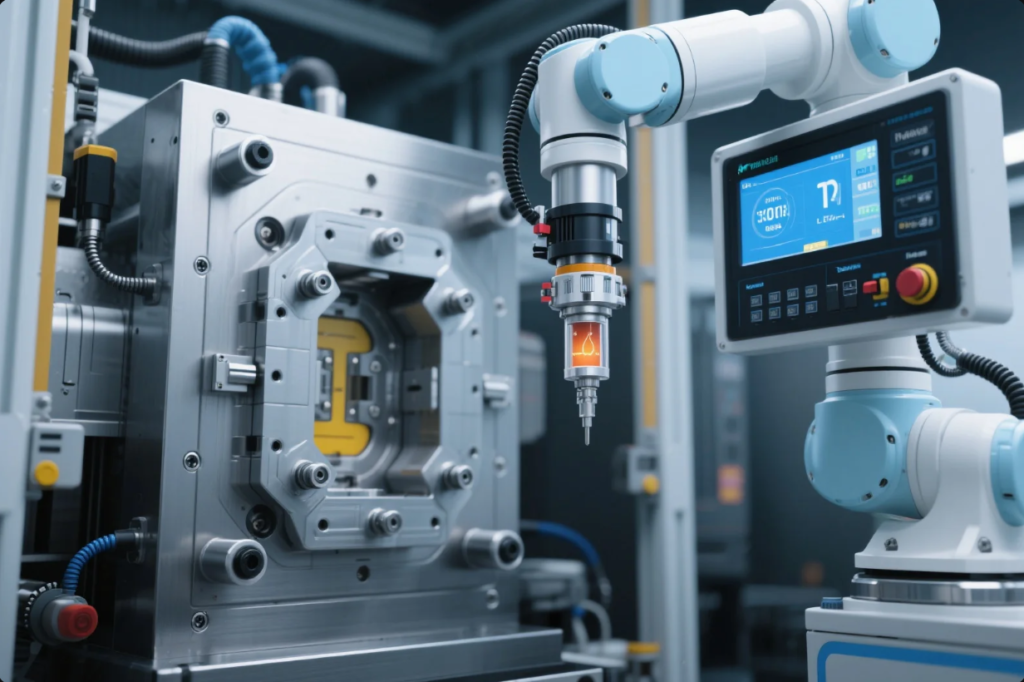

AI‑Driven defect detection & predictive maintenance

Quality control by humans overlooks critical defects.

AI-powered vision systems combined with predictive analytics dramatically reduce defects and unplanned downtime.

Vision Inspection

- Neural networks trained on real molded data identify flash, warpage, sink marks, and surface dust in real-time.

- Platforms like Cognex In-Sight and Keyence CV-X are leveraged.

- Prime configures vision zones at ejector plates to inspect every part, logging rejects instantly.

Predictive Maintenance

- Data from thermal sensors, servo current, and vibration are analyzed to predict bearing wear or hydraulic leaks.

- Systems mirror technologies in Industry 4.0 predictive analytics.

- Clients see 30% fewer unplanned stops and 25% extended mold life.

Process Optimization

- AI auto-adjusts injection speed, switch-over point, and cooling times between batches for consistency.

- Prime uses feedback loops under 200 ms—similar to systems in adaptive control research (MIT’s control labs).

Quantified outcomes:

- 40% reduction in scrap

- 33% reduction in energy use

- 20% increase in parts per shift

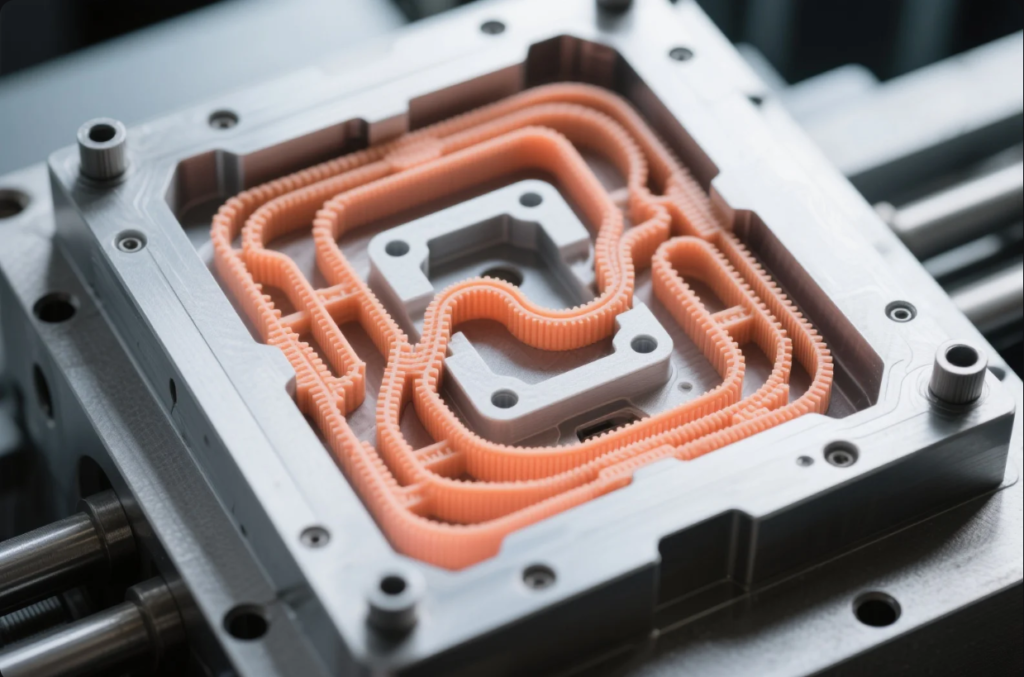

Tooling innovation: conformal cooling, nano-coatings, precision inserts

Tooling innovations directly impact production speed and part precision.

Advanced tooling techniques enable quick, precise, and durable mold performance.

Conformal Cooling

- Using metal additive manufacturing, cooling channels follow part contours—reducing cooling time by 20–30%.

- Explained well by TWI’s additive manufacturing profiles.

- Prime uses beryllium-copper inserts from GF Machining Solutions for optimal thermal conductivity.

Precision Inserts

- Core pins and inserts built via EDM or multi-axis CNC to tolerances ±0.005 mm, essential for thin-wall or electrical components.

- Sourced from established vendors like Makino Precision Tools.

Nanocoatings & Surface Treatments

- Diamond-like carbon (DLC) or DLC-PVD coatings reduce friction, part sticking, and wear—especially with filled resins.

- Research from Graphene-based coatings indicates improved mold release and corrosion resistance.

Tooling Benefits Summary

| Tooling Feature | Benefit | Result |

|---|---|---|

| Conformal cooling | Faster, uniform part cooling | 20-30% shorter cycle time |

| Precision inserts | Micron-level accuracy | Fewer rejects, better repeatability |

| Nanocoatings | Less wear & easy demolding | Longer tool life, lower maintenance |

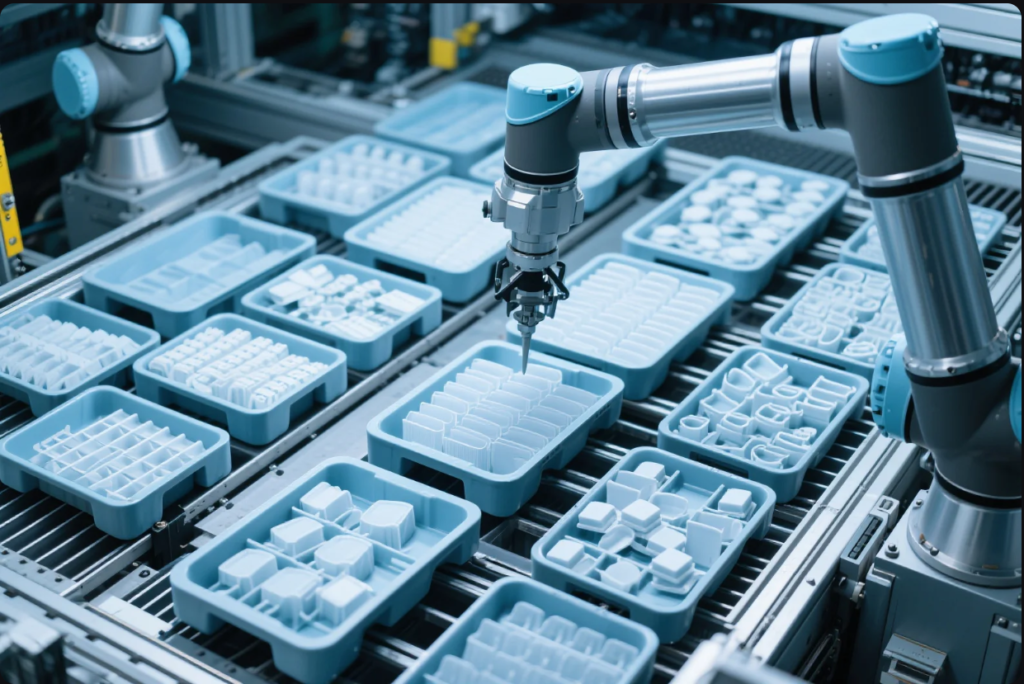

Lights‑out manufacturing: 24/7 robotic production

Human shifts limit efficiency and bring variation.

Lights-out manufacturing combines robotics and automated controls to run unmanned 24/7 production cells.

Architecture and Components

- Robotic arms (Yaskawa, ABB) perform ejection, binning, inspection, and packing.

- Safety systems follow ISO 10218 robot safety standards; sensors from Keyence provide zone protection.

- Edge computers host AI inspection and fault detection, with alerts via cloud dashboards.

Benefits

- 30–40% volume increase from continuous operation

- 100% part traceability and vision logging

- <2% defect rates during unmanned hours

According to McKinsey lights-out analysis, unmanned cells reduce labor costs by 50% and increase capacity by 70%.

Challenges & implementation roadmap

Implementing smart manufacturing is complex but rewarding.

Common Challenges

- High Upfront Costs – Integration, sensors, and training cost tens to hundreds of thousands.

- Skill Gaps – Technicians need training in PLC programming, data analysis, and AI tools.

- Cybersecurity Risk – OT/IT systems must follow standards like IEC 62443.

- Legacy Equipment – Retrofitting old presses with IO-Link systems or smart relays can help.

- Change Management – Teams resist new workflows; senior leadership must drive adoption.

Roadmap for Adoption

- 📈 Phase 1: Start with IoT retrofits and MES auditing on one line.

- 🤖 Phase 2: Add vision inspection and predictive analytics.

- 🛠 Phase 3: Roll out conformal tooling and AI-controlled cycles.

- 🔧 Phase 4: Launch lights-out cells with integrated robotics.

- 📊 Phase 5: Scale across all production, incorporating digital twins and supply chain integration.

KPIs to monitor:

- Scrap rate,

- OEE (Overall Equipment Effectiveness),

- MTBF and MTTR,

- Part cycle variability

Start small, scale fast—real ROI emerges in 18–24 months with proper KPI tracking and change leadership.

FAQs

1. Does smart manufacturing need cloud connectivity?

Hybrid models use local edge devices for control and optional cloud for analytics and reporting.

2. Can legacy machines be upgraded?

Yes. Retrofit kits from Siemens or Schneider integrate older presses into IoT ecosystems.

3. What learning curve is required?

With proper training, operators can manage systems within weeks; engineering insights arise within 2–3 months.

4. Is AI reliable in manufacturing?

Yes, modern systems exceed 95% accuracy after training. They also flag anomalies even without labeled examples.

5. Is this only for high-volume?

No. Microfactories building low-volume customized parts can also benefit—especially in medical, electronics, and optics.

Contact Us

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Conclusion

Smart manufacturing—combining IoT connectivity, AI-powered inspection, advanced tooling, and unmanned operations—is rewriting plastic part production. Partnering with Prime ensures you harness efficiency, consistency, and data-driven quality today.