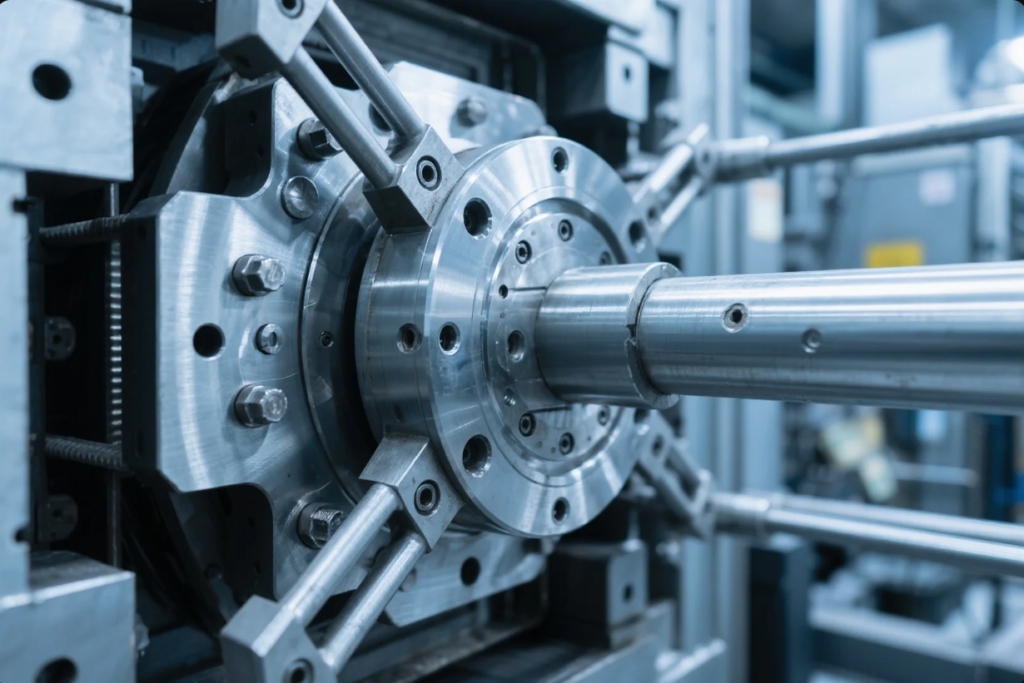

Stamping Die Maintenance: Ensuring Precision in Every Part

How stamping tolerance affects die accuracy

Stamping to a tolerance of ±0.02 mm is essential for ISO 2768 and automotive standards such as IATF 16949. Small deviations from die wear or press misalignment can cause part rejection, assembly issues, and increased scrap costs, as documented by MetalForming Magazine and ThomasNet.

Key influences on accuracy include:

- Die deflection in high-tonnage presses

- Punch tip wear impacting hole size and alignment

- Press backgauge drift affecting part position

Maintaining consistent tolerances involves:

- Press calibration per PMI Standards

- Regular die regrinding using high-precision machining centers (e.g., from Muratec)

- Use of hardened steels (D2, SKD11) cited by ASM International

Heat treatment techniques to reduce die deformation

Heat treatment improves wear resistance and dimensional stability. Techniques include:

- Vacuum hardening to prevent oxidation — used by Seco Tools

- Triple tempering to relieve stress — recommended by ASM Heat Treating Society

- Cryogenic treatment at –185°C for microstructural stabilization — practiced by Cryo-Tech Systems

- Nitriding via salt bath or gas to harden surfaces — from vendors like Bodycote

- Shot peening to induce compressive stress — researched in SAE International journals

Applying these steps prevents cracking and maintains tight die dimensions throughout production.

Common wear failures and preventive maintenance tips

| Component | Failure Mode | Preventive Action |

|---|---|---|

| Punch tip | Rounding, burrs | Use TiN-coated carbide or PVD inserts (Sumitomo Carbide) |

| Die corner | Chipping, microcracks | Perform shot peening and periodic NDT inspection per NDT.net |

| Strait stripper plates | Galling | Apply graphite or soap-based dry-film (Henkel Bonderite) |

| Guide bushings | Wear, play | Replace bushings and re-lubricate; track service per SKF Condition Shopping |

| Backing plate | Imprint wear | Use reinforced or nitrided plates, as recommended by Bodycote |

Maintaining these elements prevents sudden failure during production runs.

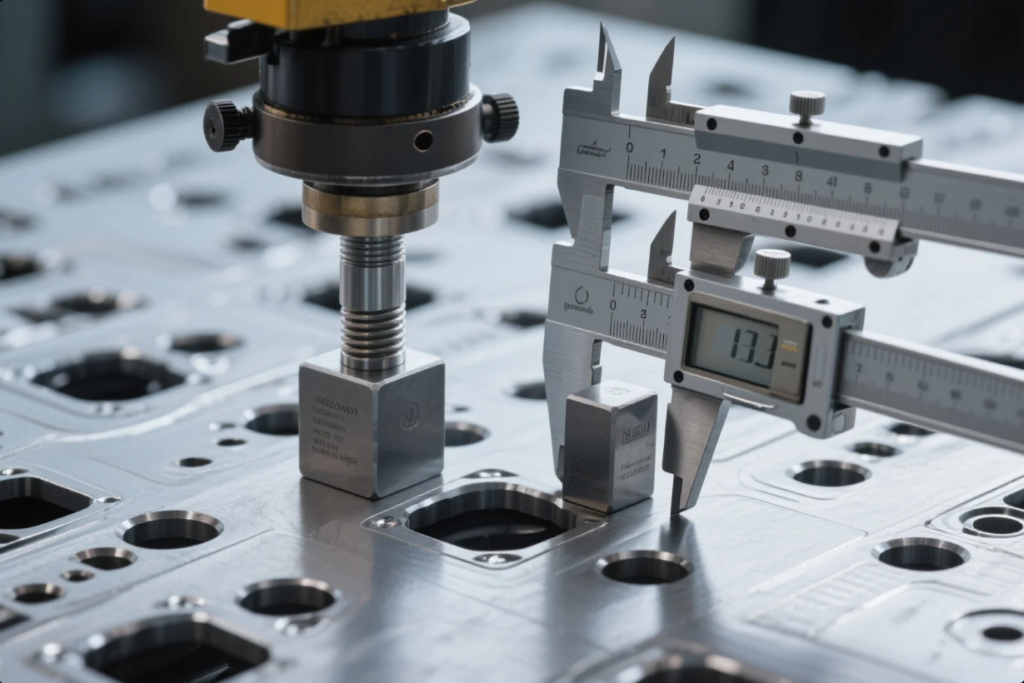

Best practices for scheduled die inspection and replacement

Planned maintenance saves costs versus emergency repairs. Prime recommends this schedule:

- Daily: Visual cleaning and lubrication

- Weekly: 0.01 mm measurement using calipers or Mahr CMMs

- Monthly: Full teardown and inspection with crack detection

- After 1M strokes: Precision regrind and dimensional re-certification

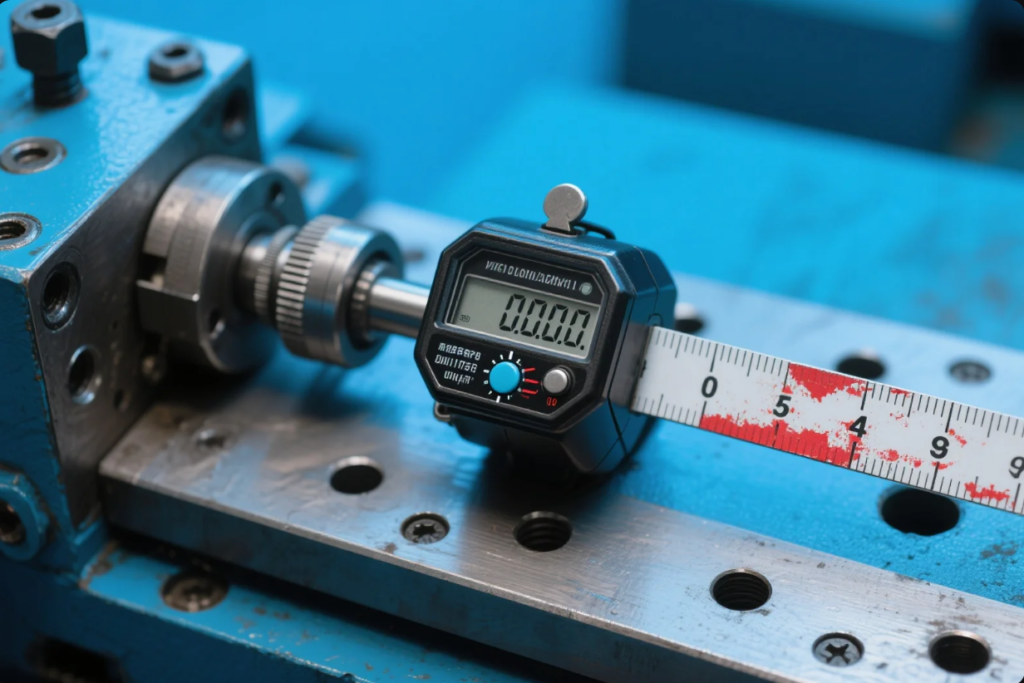

Replacement triggers:

- Punch rounding >0.03 mm

- Guide pillar misalignment >0.1 mm

- Cracks or surface failure >3 mm

Use systems aligned with IATF 16949 maintenance metrics.

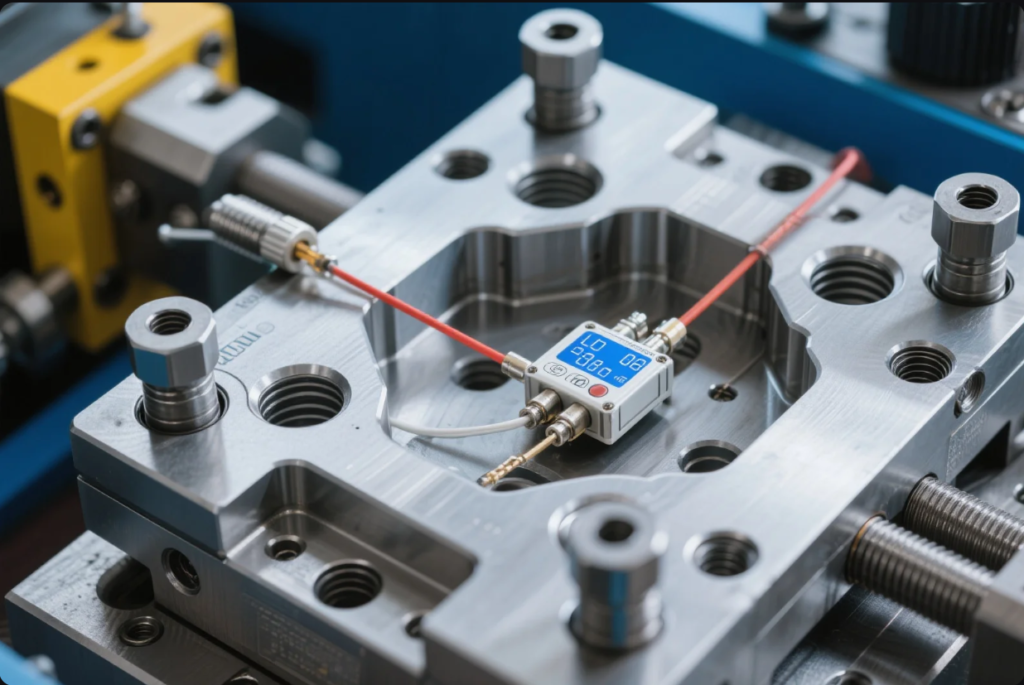

Advanced diagnostics & sensor integration

Prime installs sensors inside dies:

- Pressure transducers for blank-holder force checks (via Balluff)

- Acoustic pickups to detect unusual strike patterns (Banner Engineering)

- Thermal sensors to prevent overheating during long cycles (SICK AG)

These are part of Industry 4.0 strategies used by Rockwell Automation, enabling real-time alerts and preventive shutdowns.

Digital maintenance logs & AI‑driven prediction

Prime leverages MES systems to track:

- Stroke counts

- Regrind dates

- Inspection data and deviation history

- Machine operating conditions

AI modules can:

- Predict maintenance intervals based on wear patterns (using Siemens MindSphere)

- Forecast guide pillar lifespans via IBM Maximo analytics

- Suggest pallet or strip layout changes to reduce die wear

This optimization reduces unplanned downtime by \~25%.

FAQs

Q: What’s the most common die wear issue?

A: Punch rounding. Detect early with CMM checks after 50K cycles.

Q: How deep a crack is critical?

A: Cracks over 3 mm typically require die replacement.

Q: Can proprietary coatings help?

A: Yes — TiN, DLC coatings can extend die life 3–5× (Seco Tools).

Q: Are diagnostics sensors necessary?

A: Highly recommended for production >100k parts/month.

Q: How soon after coating is regrind needed?

A: Typically after 200–300k strokes; system alerts prompt servicing.

Conclusion

Stamping die maintenance ensures accuracy, prevents unplanned downtime, and reduces scrap. Prime’s process-driven heat treatment, layered inspections, sensor integration, and AI-optimized logs bring long-term precision and productivity gains.

Contact Prime

Ready to elevate your die performance?

- 🧰 Die regrind & coating services

- 🔍 On-site inspections & sensor retrofits

- 🔄 Digital log and AI maintenance systems

- 🌍 Global logistics support

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com