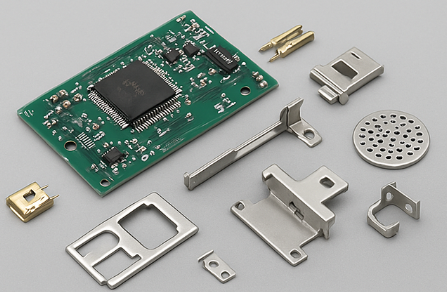

Stamping parts

The world's leading supplier of metal stamping parts.

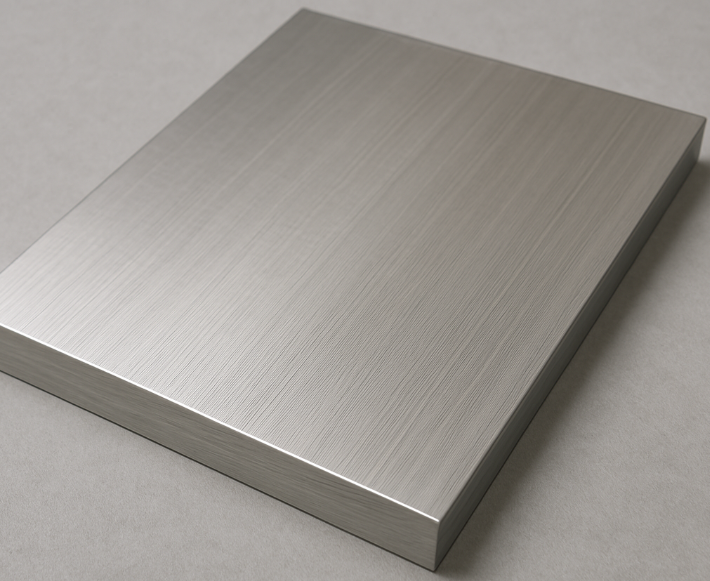

Customized metal stampings

To provide you with professional metal stamping parts solutions! Whether it is stainless steel, aluminum alloy or special alloy, relying on advanced CNC stamping equipment and multi-stage forming process, the complex structure design is accurately restored to meet the strict requirements of automobile, electronics, industrial equipment and other fields. Support custom/sample development, from rapid proofing to mass production, strict quality inspection to ensure that each product has zero defects and high durability. Let your creative precision landing, cost reduction and efficiency in one stepーー choose us, customized metal power!

Table Of Contents For This Page

At Prime, we provide you with professional service and high-quality products.

Application fields of customized metal stamping parts

Customized metal stamping parts are widely used in many industries, such as automobile, electronics, home appliances, medical equipment, machinery manufacturing and other fields. Their precision and efficiency make them ideal for making high-quality products. Through the stamping process, we can meet the needs of customers for a variety of complex shapes, thereby improving production efficiency and reducing costs.

General Hot Selling Products

Metal stamping parts are parts that can be made from sheet metal into desired shape by stamping process. Stamping processes are widely used in various fields. The following are common metal stamping processes and their characteristics and applications:

General stamping

- Features:

- Ordinary stamping is the most basic metal stamping process

- The sheet metal is pressed by a punch press for cutting, shaping, etc. .

- It is suitable for various materials, including carbon steel, stainless steel and aluminum alloy, etc

Applications:

Widely used in automobiles, household appliances, mechanical equipment, electronic products and other fields of shell.

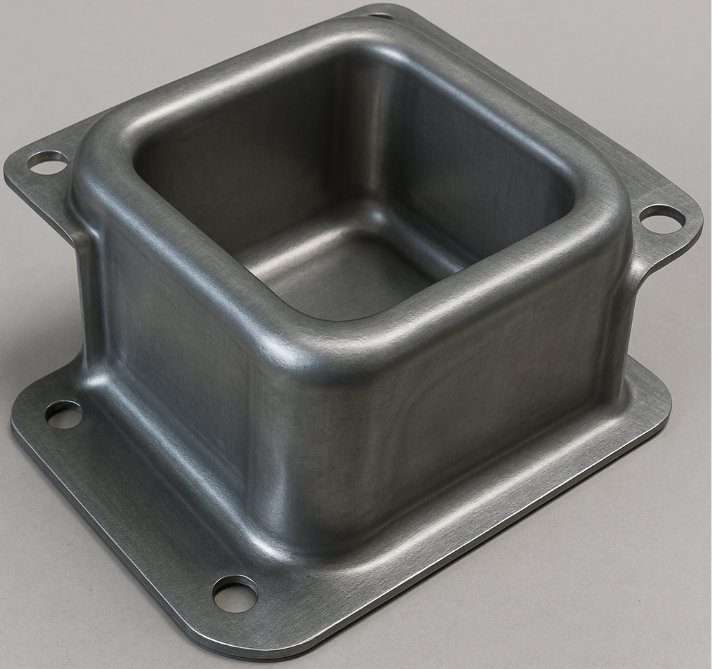

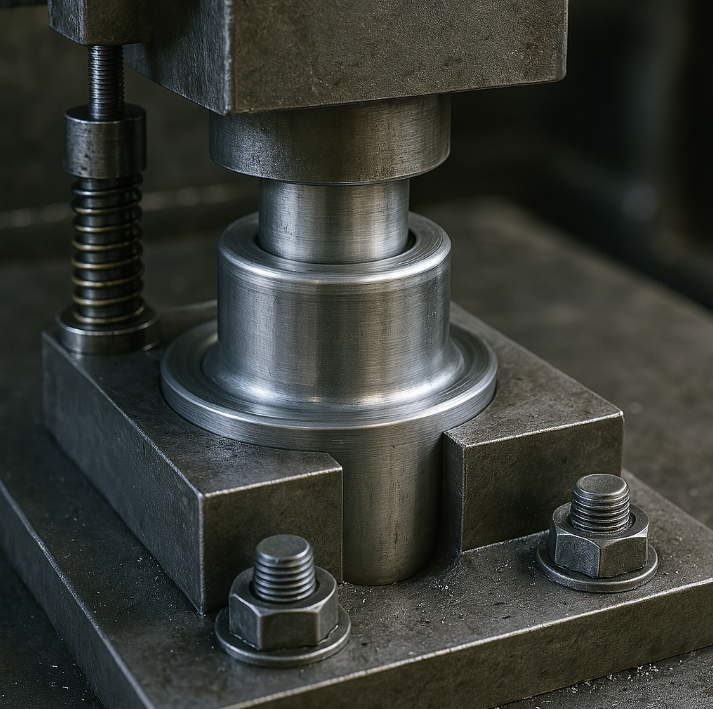

Deep drawing

- Features:

- On the basis of common stamping, deep drawing technology increases the processing ability of parts with deep depth and complex shape.

- Through the die and stamping equipment, the sheet metal under the pressure of plastic deformation, the formation of deep grooves or complex shapes.

Applications:

Deep drawing is commonly used for automotive parts (e. g. , fuel tanks, body enclosures) , appliance enclosures (e. g. , washing machine drums) , and precision instrument enclosures.

Stretching

- Features:

- Stretching is the process of stretching a sheet of metal into different shapes by pressure.

- it is suitable for the production of thin-walled and complex shape parts.

- The drawing depth is large enough to achieve more complex geometries.

Application:

mainly used in the manufacture of auto body parts, home appliances shell, electronic shell and other products.

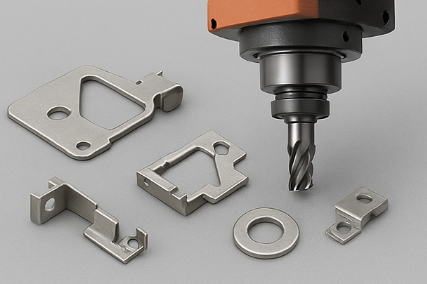

Cutting

- Features:

- The cutting process includes shearing, cutting, etc.

- The main idea is to cut the sheet metal into specific sizes or shapes as needed.

- Through the die and stamping equipment, can be fast and efficient cutting metal sheet.

Application:

Used in the production of various precision parts, such as small household appliance parts, mechanical parts, electronic component, etc. .

Embossing

- Features:

- Embossing is the process of forming a regular texture, pattern, or raised shape on a metal surface by means of a die.

- This process can not only increase the beauty of the parts, but also improve their friction resistance.

Applications:

widely used in home appliances, auto parts and decorative metal products and other fields.

Into shape

- Features:

- The forming process is to make the metal plate form a specific shape of parts in the die by stamping, stretching and other methods.

- This process is mainly used for sheet metal forming, usually with high precision molds for production.

Applications:

widely used in the electronics industry, home appliances, automobile manufacturing, machinery manufacturing and other fields.

Spinning

- Features:

- Spinning is the process of forming a sheet metal under pressure by means of a high-speed rotating die.

- It can produce large size and symmetrical metal parts with less material waste and high molding efficiency.

Application:

Commonly used in the manufacture of automotive wheels, pots, mechanical parts and other products.

Cold extrusion

- Features:

- Cold extrusion is a process by which metal is extruded through a die orifice at room temperature under high pressure.

- It is usually used to produce precision metal parts.

Application:

Widely used in the production of bolts, nuts, auto parts, electronic parts and so on.

In Summary

Metal stamping process has the advantages of high machining accuracy, high production efficiency and good product consistency. It can produce complex shape, high precision parts, widely used in household appliances, automobiles, medical equipment, machinery manufacturing and other industries. According to different requirements, selecting the appropriate stamping process can effectively improve production efficiency and product quality.

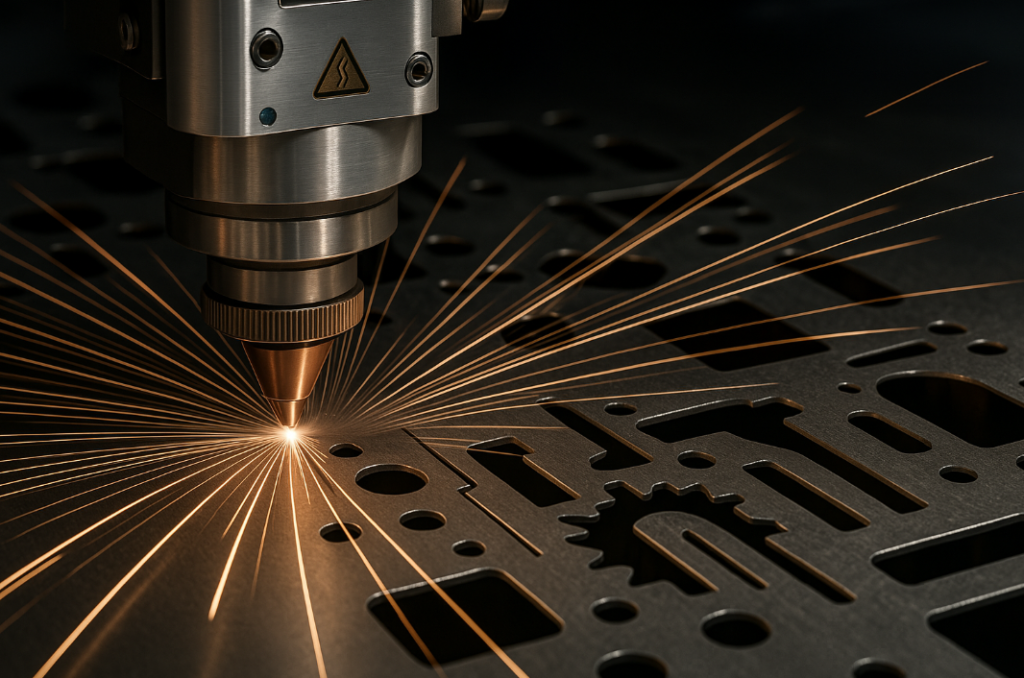

The Process Flow & Duration Estimation

Metal stamping process is a process that the metal sheet is processed into the required shape by external force. This process involves several steps, each of which is significant. The following are the main steps in a metal stamping process:

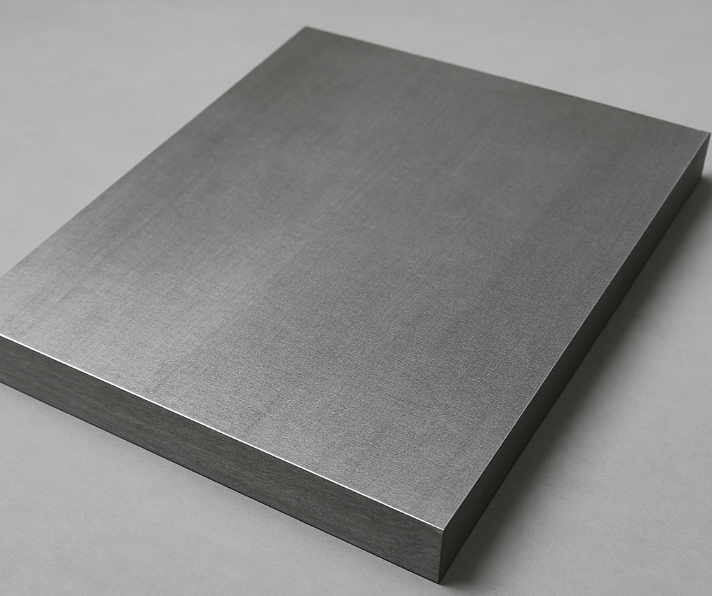

Step 1: Preparation of raw materials

In metal stamping process, the raw material is usually sheet metal, so it is very important to choose the right material. The raw materials need to be cleaned and degreased before stamping to ensure that there are no impurities on the surface to avoid defects during processing.

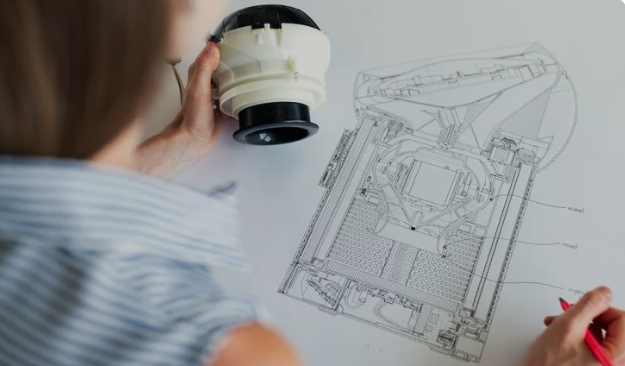

Step 2: Design and manufacture of die and mould

Die is the core of metal stamping process, which determines the precision and shape of the product. Die design must be based on product requirements to ensure efficient and accurate completion of the entire stamping process.

Step 3:Stamping Process

The stamping process usually consists of the following operations:

Blanking: cutting of a sheet metal into a desired shape by pressure.

Drawing: the drawing of a sheet of metal into a deeper shape, usually to make tubular or deep-shaped parts.

Bend: to bend a sheet of metal to a desired angle by means of a die.

Forming: the shaping of a sheet metal into complex geometries by pressure.

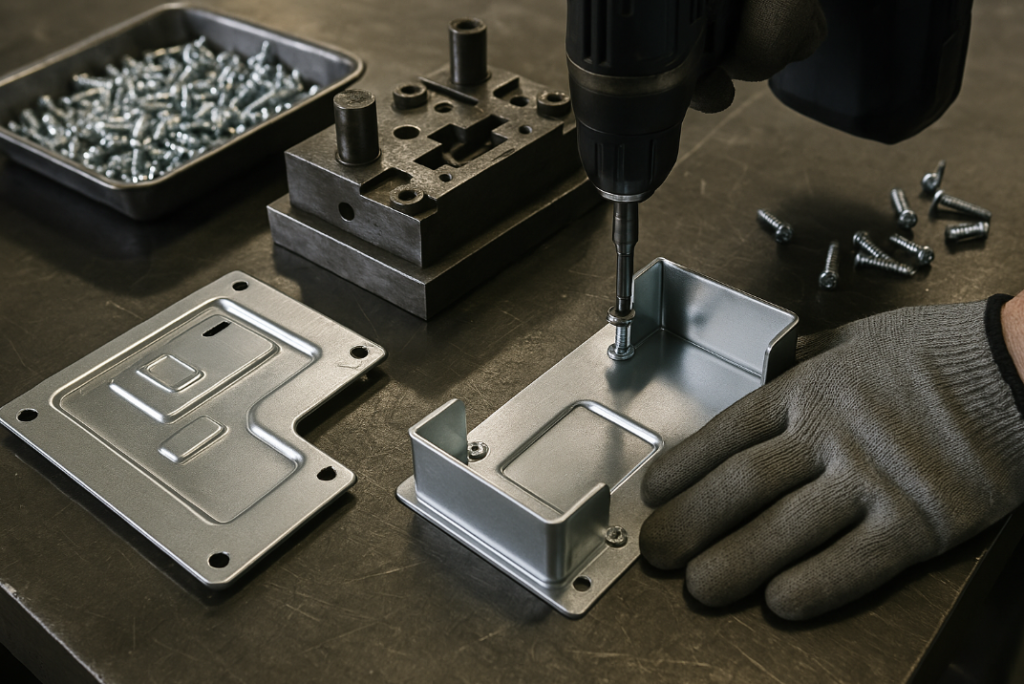

Step 4: Deburring and surface treatment

The parts after stamping usually have burrs and need to be deburred. In addition, surface treatment steps such as spraying, galvanizing, phosphating, etc. , can improve the durability and appearance of the product.

Step 5:Quality inspection

After stamping, the parts need to be checked to ensure that their size, shape and surface quality meet the design requirements. This usually includes visual inspection, dimensional measurement, and performance testing.

Step 6: Follow-up machining and assembly

Some stamping parts may also need further processing, such as drilling, tapping, etc. . In addition, some parts also need to be assembled to complete the production of the final product.

Step 7: Packaging

- PE film packaging: metal stampings are usually first covered with a layer of PE film (polyethylene film) . PE film can effectively prevent the metal surface moisture, rust and friction with other objects caused by damage. The film also acts as a protective layer to prevent scratches on the metal surface.

- Carton packaging: Metal Stampings made of PE film are usually placed in strong cartons. Cartons can be customized to the shape and size of the product to ensure proper sizing and to avoid gaps in the package that could cause parts to collide with each other.

- Wooden case packing: metal stampings sealed with PE film and cartons are placed in strong wooden cases. And then ready to deliver.

Step 8: Delivery of finished product

Upon completion of all inspection and post-processing, the castings will become the final product, ready to be delivered to the customer or used for assembly.

Want to know how to compress lead times?

In order to shorten the production and delivery cycle, we suggest that you tell us your needs in detail, and we will adjust the strategy flexibly according to your requirements to ensure your production and help you succeed!

The Common Pitfalls When Purchasing

Please note that the final cost depends on the customized service you require, the specifications of the raw materials used, the relevant national laws, and the distance of transportation. Take the example of booking a tall container of products:

- Improper material selection: improper material selection may lead to stamping parts can not reach the strength, corrosion resistance and other performance requirements, affecting the service life.

- Poor design: immature design can lead to difficulties in the production of stamping parts, increased costs and delays in delivery.

- Supplier is not reliable: some unprofessional suppliers may not be strict in quality control, resulting in substandard products or delivery is not timely.

Materials used for stamping parts

Stampings usually use a variety of different materials, depending on the application requirements and process requirements. Here are some common types of materials:

Cold rolled steel sheet (CRS)

Widely used, relatively low cost, suitable for most light stamping parts.

Smooth surface, easy to handle and paint.

Hot rolled steel plate (HRS)

Higher strength, suitable for the production of more tough stamping parts.

Used in automotive, construction and heavy machinery industries.

Aluminum alloy

Strong corrosion resistance, suitable for high durability and anti-corrosion requirements of the occasion, such as food processing, chemical equipment.

Common stainless steel types include 304,316, etc. .

Aluminum

Lightweight, good corrosion resistance, suitable for aerospace, automotive, electronic products and other fields.

Easy processing, can provide excellent surface effect.

Copper alloy

Excellent electrical and thermal conductivity, commonly used in electrical equipment and electronics industry.

Good corrosion resistance, especially suitable for electrical connector and connectors.

High Strength Steel (HSS)

Extremely high strength, suitable for high pressure, high temperature requirements of industrial environment.

Common in the manufacture of automotive parts, industrial machinery, etc.

Stainless steel

The stainless steel materials used in metal stampings usually have good corrosion resistance, strength, and workability, and are often used in applications that require wear resistance, high temperature resistance, or corrosion resistance.

The selection of suitable materials will directly affect the quality and service life of stamping parts.

A Brief Self-Nomination, Why Choose Prime?

Choose Us, you will get affordable, high-quality, on-time delivery of metal stamping solutions.

Experience: We have more than 30 years of stamping production experience, can provide a variety of industries with high-quality customized metal stamping parts.

Professional team: Our engineering team is familiar with the stamping process and can provide precise design and production services.

High quality assurance: We are ISO 9001 certified to ensure that each stamping meets the highest standards of quality.

Rapid Response: We are committed to providing fast sample production and production cycle, to ensure that your needs can be met in a timely manner.

Global Services: No matter where you are, we can provide you with quality services to ensure the smooth progress of your business.

Get in touch

Custom Hardware Parts Made Easy

Share detailed information about your needs, including drawings, reference images, and any specific ideas or specifications you have in mind.

Based on your requirements and design, we’ll provide a custom solution and send you a detailed quote within 24 hours.

Once you approve the design and quote, we’ll begin mass production and take care of the shipping, ensuring timely delivery.

Get a Free Quote

Reach out to us for a free quote and expert advice on your custom hardware needs. At Prime, we’ll provide the right solution for your project, ensuring quality and precision every step of the way.