Standardization in Metal Stamping Dies: Why It Matters

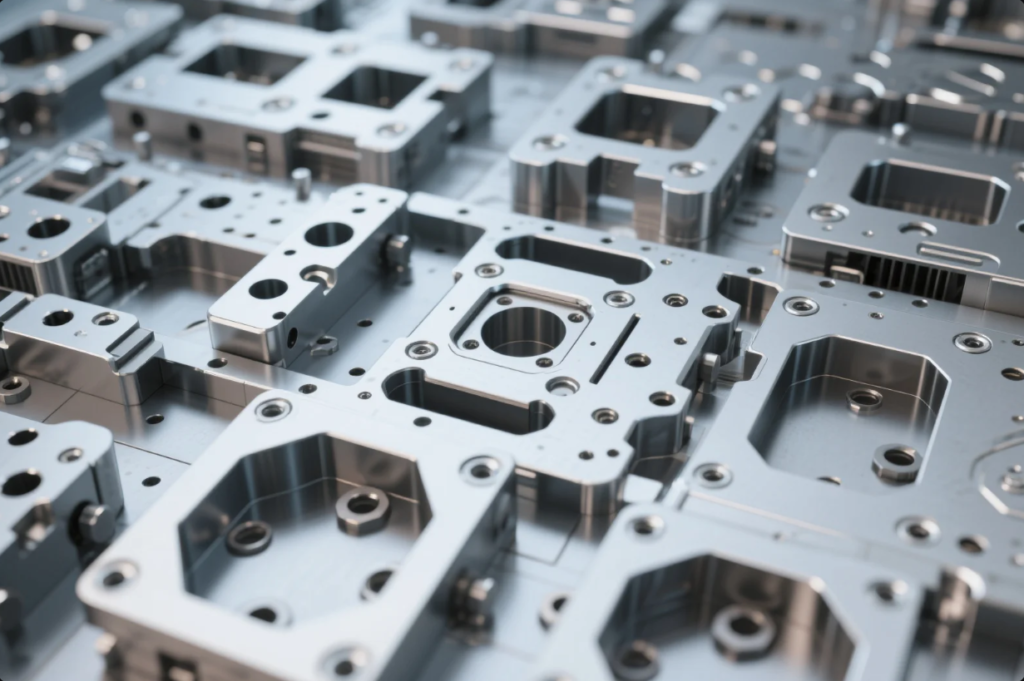

Modular die components: Benefits for tooling consistency

Standard modules such as punch blocks, stripper plates, and guide pillars simplify sourcing and reduce lead time. Industries like automotive and consumer electronics rely on systems from Meusburger and MISUMI to ensure consistent fit and performance.

Key Benefits:

- Faster repairs and replacements

- Consistent part dimensions globally

- Lower inventory of spares

- Easier scalability for different press models

For modular die adoption, see insights from SME Tooling Guide and Die & Mold Industry Forum.

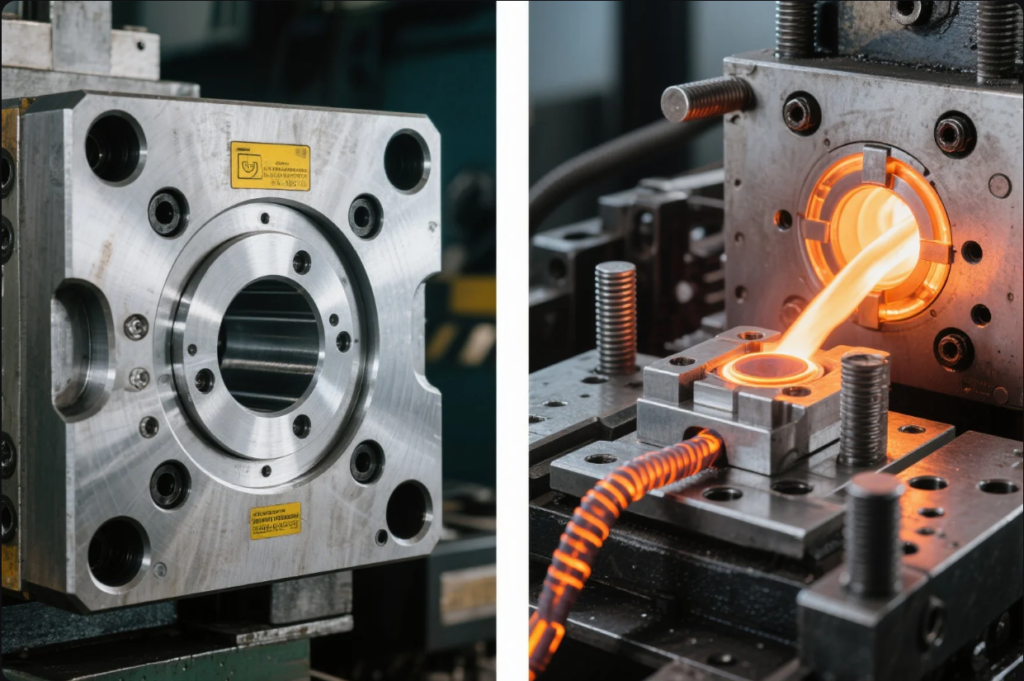

Cold stamping dies vs. hot forming dies

Cold stamping works at room temperature and is ideal for steel, aluminum, and brass with tight tolerances. Press tonnage ranges 25–300 ton. Hot forming, by contrast, uses heating (300–900°C) to shape high-strength steels like 22MnB5 into advanced auto parts.

| Feature | Cold Stamping | Hot Forming |

|---|---|---|

| Temperature | Room temperature | Up to 900°C |

| Materials | Steel, aluminum, brass | Boron steel, titanium, Inconel |

| Die Materials | Tool steel, carbide, coatings | High-temp alloys, nitrided steels |

| Surface Finish | Ra <1.6 for auto/exterior parts | Coarser finish (Ra 3–6) acceptable |

| Tonnage Requirements | Moderate (25–300 ton) | High (500+ ton presses) |

| Use Cases | Sheet metal enclosures, brackets | Auto structural bodies, chassis |

Hot forming tools use induction heaters and coatings like Tungaloy heat-resistant alloys. Read more at IFHTSE and SAE Hot Stamping News.

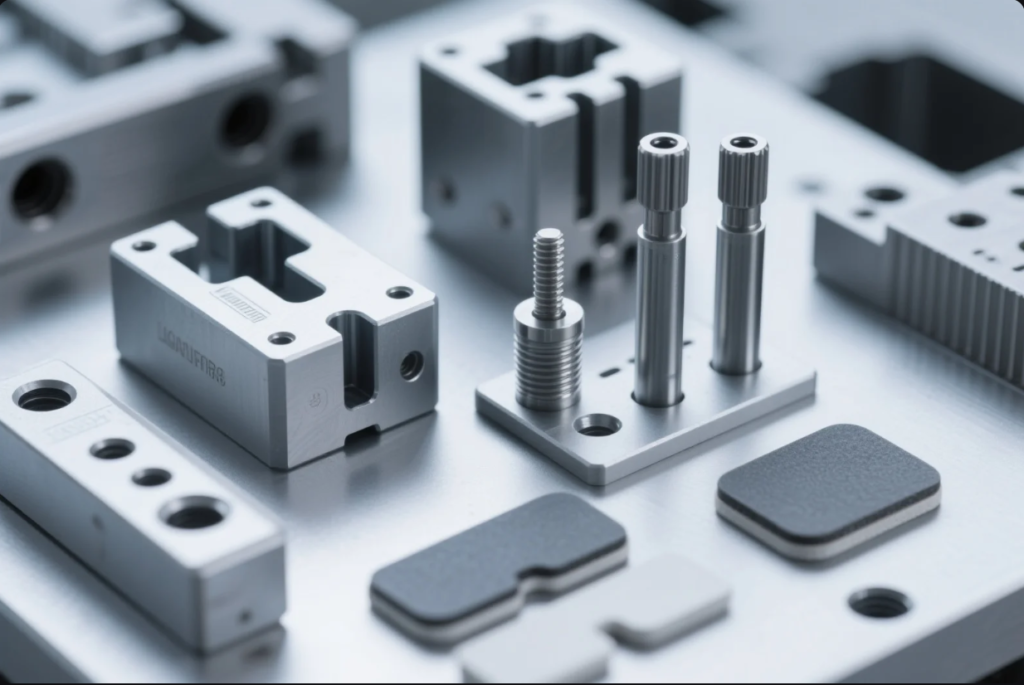

Why standard die dimensions reduce lead time and cost

Standard die thicknesses and guide pillar sizes from suppliers like Hasco and DME enable:

- Quicker procurement of components

- Fewer machining steps and setup time

- Easier maintenance with modular units

- Bulk pricing on standard plates and guides

Prime uses in-house standards aligned with DIN 650 and ISO 9001, reducing lead time by \~30% and cutting costs by \~20%.

Supporting data from Kennametal, B\&R Industrial Automation, and Industry 4.0 hubs highlight efficiency gains.

Supporting global production with interchangeable tooling

Standardized tooling across locations ensures:

- Global production consistency

- Minimized shipping for spare parts

- Faster repair via local suppliers

- Easier training for local operators

Large OEMs like VW and Toyota use IATF 16949-approved tooling from global sources with zero-downtime expectations. Die Reset services from Forging Industry Association support this model.

FAQs

Q: Can modular die parts compromise precision?

A: No—modern modules are precision-ground to tighter than ±0.005 mm, e.g. from Meusburger.

Q: Are hot forming dies more expensive?

A: Yes. They require heat-resistant materials, heaters, and heavy presses. Cost is higher, but needed for boron steel components.

Q: Will standard guide pillars reduce die life?

A: Not if proprietary coatings and nitriding are used—Hasco X·button pillars last longer.

Q: How to transition a custom die into standardized modules?

A: Redesign base plates and add modular pockets—Prime can assist.

Q: Can this help small-volume runs?

A: Yes. Standard components reduce upfront cost even for low-volume projects.

Conclusion

Standardized stamping dies deliver consistency, speed, cost savings, and global interoperability. Whether modular, cold-forming, or hot-forming, standardized tooling ensures high ROI and quality.

Contact Prime

Want to streamline your die design and global stamping setup?

- 🔧 Modular die design and rebuild

- 🔥 Cold or hot forming tool expertise

- 🌍 Global tooling compatibility service

- 🚚 Fast worldwide shipping

📩 Email: [email protected]

🌐 Website: https://primecustomparts.com