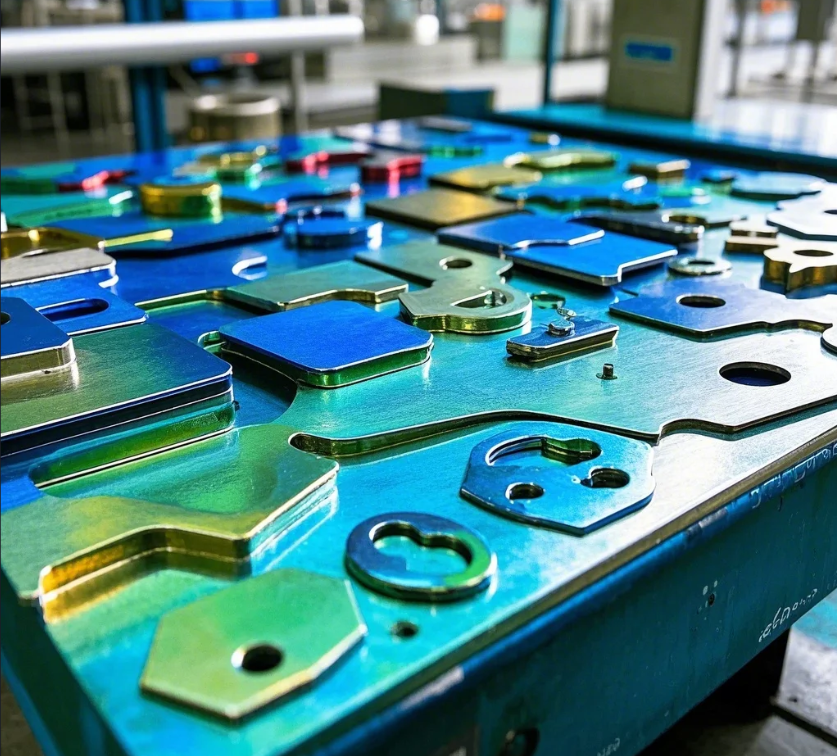

Surface treatment

Surface treatment

Precision surface treatment, create excellent metal products, Excellence, only for your trust.

Professional metal surface treatment technology

Metal surface treatment is a key step to ensure long-term durability of metal materials in a variety of environments. Through different surface treatment technology, we can greatly improve the corrosion resistance, wear resistance and appearance quality of metal products. We provide customers with a comprehensive metal surface treatment services to ensure that each product has excellent performance and beautiful appearance.

Our metal surface treatment technology:

Metal surface treatment technology is a common method to improve the surface properties of metal materials, which can improve the wear resistance, corrosion resistance, oxidation resistance, decoration and other properties of metal. The following is a detailed description of the main types, characteristics and applications of metal surface treatment techniques:

Surface coating technology

Electroplating

Features:

A thin layer of metal or alloy plated on a metal surface by electrolysis, usually to improve its appearance, corrosion resistance, or hardness.

Applications:

Widely used in automobiles, home appliances, electronic equipment and decorative products. For example, auto parts, electrical connectors, jewelry, etc. .

Spraying

Features:

Spray paint, metal powder and other materials evenly coated on the metal surface, enhance its corrosion resistance, high temperature resistance or decorative effect.

Applications:

Commonly used in industrial equipment, aerospace, automotive, construction and other fields, to prevent metal surface oxidation or corrosion.

Heat Treatment

Features:

By heating the metal to a certain temperature and maintaining a certain time after rapid cooling to change the metal’s crystal structure and properties, such as hardness, strength, plasticity and so on.

Application:

Mainly used to improve the mechanical properties of metals, such as steel, aluminum, copper alloy hardness and wear resistance. Widely used in automotive, machinery manufacturing and other industries.

Surface chemical treatment techniques

Electroless

Features:

Electroless plating is a non-current electroplating method, using chemical reaction will be deposited on the surface of the metal coating. Common electroless plating metal nickel, silver, gold and so on.

Applications:

Electroless plating can be in complex shape and precision parts on the uniform coating, widely used in electronics, automotive, aerospace and other fields, especially in the need for corrosion and high wear-resistant occasions.

Passivation treatment

Features:

Passivation is the formation of a thin protective film, usually an oxide film, on a metal surface by a chemical reaction. Common passivating metals are aluminum and stainless steel.

Applications:

Mainly used to improve the corrosion resistance of metal, widely used in chemical, food, medical and other fields, has an important protective effect on stainless steel pipes and equipment.

Anodizing

Features:

Anodizing is an electrochemical surface treatment technique that uses an electrolytic process to form an oxide film on the surface of a metal. It is commonly used on aluminum and its alloys.

Applications:

Anodizing improves the corrosion resistance, hardness, and aesthetics of metals and is widely used in aerospace, automotive, building materials, and consumer electronics industries.

Surface physical treatment

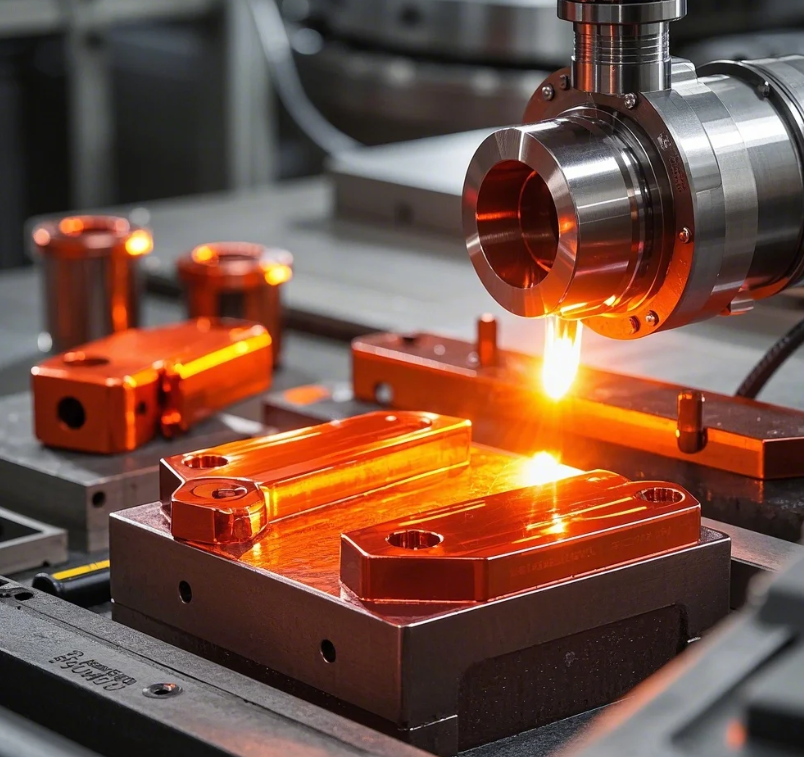

laser melting spray

Features:

local melting of a metal surface by a high-energy laser beam and forming an alloy layer with the sprayed metal powder. Has good wear resistance and corrosion resistance.

Applications:

Widely used in aerospace, automotive manufacturing and mechanical repair and other fields, especially for high-end manufacturing and surface treatment of precision components.

laser hardening

Features:

Laser hardening is a technique in which a laser beam is used to heat a metal surface and cool it rapidly to form a layer of high hardness. This technology can improve the wear resistance, corrosion resistance and fatigue strength of metal surface.

Applications:

Widely used in automotive, aerospace, tool manufacturing and other fields, mainly used to improve the service life of mechanical parts.

Heat treatment

Surface hardening

Features:

Surface quenching is by heating the metal surface to a certain temperature, rapid cooling, make the metal surface hardening, enhance its wear resistance and corrosion resistance.

Applications:

Mainly used in tool manufacturing and mechanical parts, especially those that bear higher loads, such as gears, bearings, etc. .

Carburizing

Features:

Carburizing is the process of exposing a metal surface to a carbon-containing atmosphere and allowing carbon atoms to penetrate the metal surface at high temperatures to form a hardened layer.

Applications:

Carburizing treatment is often used to improve the surface hardness of parts, widely used in auto parts, mechanical parts and other fields.

Nitriding

Features:

Nitridation is the formation of a nitride layer on a metal surface to increase its hardness, wear resistance, and corrosion resistance. Commonly used in steel.

Applications:

Nitridation is commonly used in tools, bearings, gears and other mechanical parts to significantly increase their life.

Surface repair technology

Arc Welding

Features:

ARC welding is a technique for repairing the surface of metal by melting it with the heat generated by an arc.

Applications:

ARC welding repair technology is widely used in the repair and remanufacturing of machinery, steel structures and heavy industrial equipment.

Thermal spray repair

Features:

Thermal spray repair technology involves spraying molten metal onto a surface to form a protective layer or repair surface defects.

Applications:

commonly used to repair surface damage to metal parts, especially in aerospace, automotive and energy fields.

In Summary

There are many kinds of metal surface treatment technology, each with its own characteristics. According to different requirements, the appropriate treatment technology can be selected to improve the performance of the metal. Coating Technology, chemical treatment, physical treatment and heat treatment can effectively improve the durability, appearance and other characteristics of metal. Through the application of these technologies, it can meet the high standard requirements of metal materials in different industrial fields.

Get in touch

Custom Hardware Parts Made Easy

Share detailed information about your needs, including drawings, reference images, and any specific ideas or specifications you have in mind.

Based on your requirements and design, we’ll provide a custom solution and send you a detailed quote within 24 hours.

Once you approve the design and quote, we’ll begin mass production and take care of the shipping, ensuring timely delivery.

Get a Free Quote

Reach out to us for a free quote and expert advice on your custom hardware needs. At Prime, we’ll provide the right solution for your project, ensuring quality and precision every step of the way.