The Complete Manufacturing Process of Cylinder Neck Rings: From Design to Mass Production?

Cylinder neck rings are the unsung heroes of industrial gas cylinder safety. They look simple, but a flawless neck ring is the result of dozens of technical steps—each designed to guarantee the highest levels of safety, fit, and global compliance. When procurement teams or engineers ignore even one detail, the risk of gas leaks, costly downtime, or failed audits skyrockets. That’s why industry leaders trust only experienced partners and documented processes for every order.

Prime has specialized in the full-process, large-scale manufacturing of cylinder neck rings for over 20 years. We handle every stage: design review, certified material procurement, CNC machining, thread cutting, surface protection, quality testing, and logistics. Our one-stop service helps international buyers meet the toughest standards in North America, Europe, the Middle East, Australia, and beyond.

This guide covers the critical details of each production stage—showing what goes into every Prime neck ring, why each detail matters, and how to avoid the most common pitfalls that cause pain for buyers and engineers.

Reviewing Customer Drawings and Material Procurement for Neck Rings

A successful cylinder neck ring starts with the customer’s drawings. Unclear tolerances, missing thread specs, or vague surface finish instructions all create risk. At Prime, our engineers run a detailed kick-off process:

- Initial Drawing Review: We use AutoCAD and SolidWorks to open, simulate, and cross-check every feature—threads, sealing faces, and markings.

- Tolerance and Material Consultation: If a dimension or tolerance is not industry standard, we suggest changes to match ISO 9809, EN 1442, or DOT 3AA.

- Material Sourcing: All steel is purchased from Baosteel, Tisco, or ArcelorMittal, and batch certificates are verified through Intertek or SGS.

- Digital Documentation: We manage revisions and sign-offs in a PLM system so both sides always work from the latest approved version.

Dive Deeper: What Can Go Wrong at the Drawing and Material Stage?

If drawings use an obsolete standard or don’t match the customer’s local regulations, production halts or shipments get rejected at customs. If material is bought from an unverified source, the risk of traceability loss or recall is high.

| Challenge | Prime’s Solution | Impact |

|---|---|---|

| Vague/old specifications | Digital simulation, standard alignment | Meets global standards |

| Non-certified materials | Only certified, tested sources | No supply chain or customs issues |

| Poor documentation control | Versioned PLM, multi-stage sign-off | Fast troubleshooting, full history |

Understanding International Cylinder Neck Ring Standards

Global buyers must ensure that every neck ring meets relevant ISO, EN, and DOT standards. Failure to comply can lead to legal problems, insurance denial, or customer rejection.

Prime studies your market’s requirements before the first cut. For North America, we use DOT 3AA. For Europe, it’s EN 1442. Middle East and Australia may request ISO 9809 or custom specs.

We work directly with TÜV, BV, and DNV for third-party audits.

Dive Deeper: Why International Standards Matter

A global buyer in the oil and gas sector once failed a large contract because the neck rings had incorrect thread pitch for their regional valves. The result? \$250,000 in lost sales, and a hard lesson in the cost of ignoring standards.

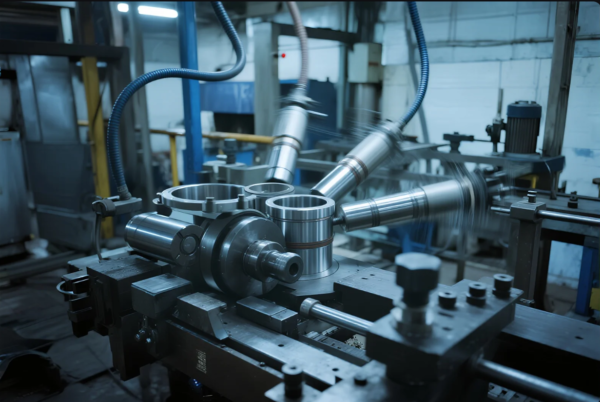

CNC Machining, Thread Cutting, and Fine Finishing Techniques

Once drawings and materials are confirmed, manufacturing begins. Prime uses advanced Haas CNC lathes and multi-axis machining centers. Every program is simulated in CAM software to prevent tool collisions or program errors.

- Thread Cutting: We use automated thread gauges and camera inspection. All threads are checked to ISO 965 or ANSI for pitch, depth, and class.

- Finishing: After turning, every sealing face is polished and deburred using automated burr removal and inspection with CMM machines.

- Batch Production: Our lines support both large (10,000+) and small custom orders, with tooling set up for quick changeover.

Dive Deeper: Preventing Machining and Thread Defects

We learned early that hand-threaded or manually finished rings caused up to 8% reject rates and customer complaints about leaks or valve installation issues. After investing in full automation and digital QC, our defect rate dropped below 0.5%—and most defects are now caught before shipping.

| Process Step | Tool/Method | Quality Control |

|---|---|---|

| CNC turning | Live tooling, digital program | Tool wear detection |

| Thread cutting | Digital gauges, in-line vision | 100% batch scanning |

| Polishing/finishing | Automated deburrers, CMM flatness check | Digital surface profiling |

Surface Treatment Options: Electroplating, Powder Coating, and Anti-Corrosion

Untreated steel rusts quickly—especially in coastal or humid areas. Our finishing department offers:

- Electroplating: Zinc, nickel, or chrome plating for general corrosion protection.

- Powder Coating: Custom RAL/Pantone colors, branding, or safety coding.

- Passivation: Stainless steel rings receive acid cleaning and neutralization for maximum rust resistance.

- Specialty Coatings: For severe chemical or outdoor service, we offer epoxy or PTFE coatings.

Dive Deeper: Testing and Documenting Surface Quality

Every batch is tested per ASTM B117 for salt spray and per ISO 9227 for corrosion. We log thickness using Fischer XRF machines. Photos and test records go in your digital order file.

Quality Assurance: Mechanical and Air-Tightness Testing for Every Batch

Prime tests 100% of dimensions, threads, and sealing faces before packaging. For mechanical and air-tightness:

- Strength Testing: Random samples pulled to failure using Instron tensile machines.

- Hydrostatic Testing: Each batch is tested at 1.5x max working pressure (per ISO 9809), with data stored for traceability.

- Leak Testing: Random rings tested with compressed air and helium mass spectrometry for micro-leaks.

Dive Deeper: International Inspection and Customer Audits

Many buyers send SGS, Intertek, or Bureau Veritas for on-site inspection. We’re happy to support third-party audits and provide FAI/PPAP documentation.

| Test Type | Frequency | Record Format |

|---|---|---|

| Dimension/thread | 100% | Digital, batch-linked |

| Hydrostatic/air-tight | 2-5% per lot | Video/photo, certificate |

| Strength/impact | 1-2 per batch | Mechanical test report |

Efficient Packaging, Warehousing, and Logistics

Proper packaging is the final step to prevent shipping damage. Prime uses:

- Custom Foam and Box Sets: Per ULINE and Sealed Air guidelines.

- Export Marking: All cartons labeled per ISPM 15 and customer branding.

- Warehousing: Clean, climate-controlled space for up to 3 months free storage before shipment.

- Global Logistics: Fast DHL, FedEx, or Maersk shipping.

Best Practices for Communication and Project Management

A great product is built on great communication. Prime responds to all emails within 12 hours, offers video calls for urgent issues, and provides order tracking and digital documentation for every batch.

- Kickoff Meetings: Video call before production starts, covering all specs and key milestones.

- Regular Updates: Weekly progress emails with photos, or daily for urgent orders.

- Transparency: All test data, photos, and documents available in a shared folder.

- Support: We offer technical support for installation or maintenance and can help with customs clearance.

FAQs: Cylinder Neck Ring Manufacturing

Can you make both standard and custom neck rings?

Yes. We manufacture all ISO/DOT/EN-standard and custom designs, with drawings from the client or our engineers.

How do you ensure every thread is in spec?

CNC cutting and digital gauges. Every batch is 100% inspected, and we can provide CMM or video proof.

What is your typical lead time?

Samples: 7-10 days. Mass orders: 2-4 weeks depending on quantity and finish.

Can I request urgent air freight?

Absolutely. We work with DHL, FedEx, and UPS.

Are all certificates and test reports provided?

Yes. You receive material certs, QC reports, and all export documentation with each shipment.

Contact Us

Looking for a reliable, ISO-certified neck ring manufacturer with full process transparency and fast delivery?

Visit https://primecustomparts.com/

Email: [email protected]

Conclusion

Cylinder neck ring manufacturing is a chain with no weak links—from drawings and steel to packaging and shipment. Prime’s robust process, ISO documentation, and experienced team guarantee quality you can trust, on every order, worldwide.