The Ultimate Guide to Metal Stamping Parts: Processes, Applications, and Industry Innovations

I. Introduction

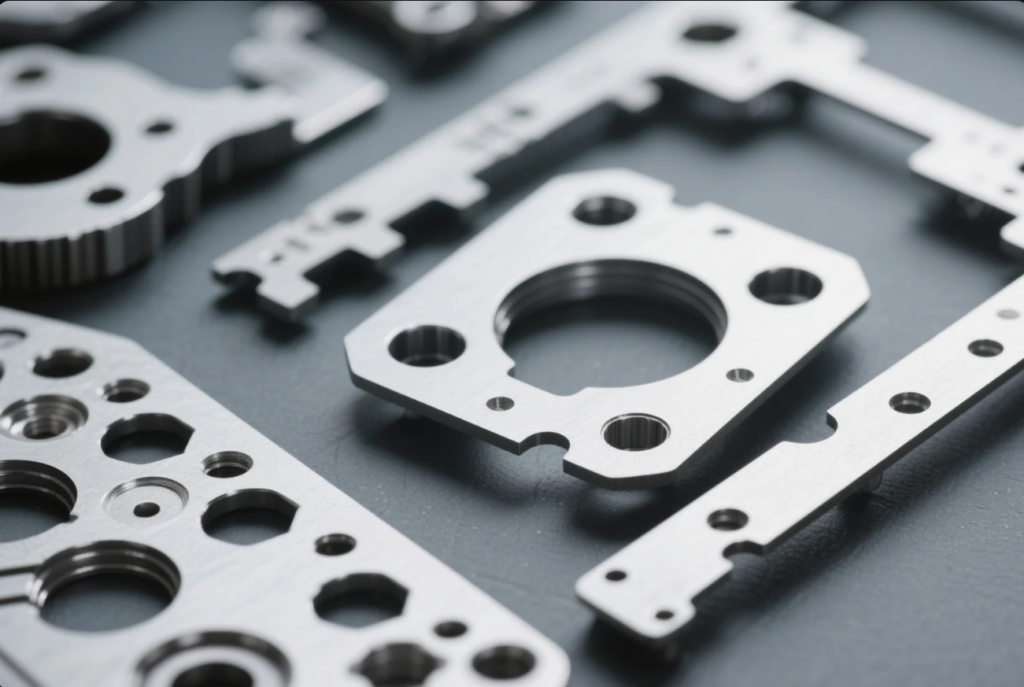

Metal stamping parts are ubiquitous yet often unseen components that form the backbone of countless products across diverse industries. From the intricate connectors within your smartphone to the structural elements of an aircraft, these precision-engineered metal pieces play a critical role in modern manufacturing. This guide delves deep into the world of metal stamping parts, offering a comprehensive exploration of the processes, materials, applications, and innovations shaping this vital sector. Historically, metal stamping evolved from rudimentary manual pressing techniques to highly sophisticated, automated processes. The Industrial Revolution spurred initial advancements, but the 20th century, particularly with the rise of the automotive industry, saw exponential growth in stamping technology. Today, metal stamping stands as a cornerstone of mass production, valued for its speed, cost-effectiveness, and ability to produce complex geometries with remarkable consistency. The global metal stamping market is a significant economic force. Industry reports estimate its value exceeded USD 200 billion in 2024, with projections indicating steady growth driven by demand in automotive (especially electric vehicles), electronics, aerospace, and medical device sectors. Understanding the nuances of metal stamping parts is therefore crucial for engineers, designers, procurement professionals, and anyone involved in product development and manufacturing. This ultimate guide aims to equip you with the knowledge needed to navigate the complexities of metal stamping. We will cover: – Detailed breakdowns of various stamping processes.

- In-depth analysis of material science considerations.

- Essential design guidelines for manufacturability and cost optimization.

- A survey of key industry applications and their specific requirements.

- Quality control methodologies and industry standards.

- Economic factors influencing project decisions.

- Future trends shaping the evolution of metal stamping.

By the end of this guide, you will have a robust understanding of metal stamping parts, enabling you to make informed decisions, optimize designs, and effectively collaborate with manufacturing partners.

II. Comprehensive Breakdown of Metal Stamping Processes

Metal stamping encompasses a range of techniques used to shape sheet metal into desired forms. The choice of process depends on factors like part complexity, production volume, material type, and required precision. Here\’s a detailed look at the most common and significant metal stamping processes: ### Progressive Die Stamping

Progressive die stamping is arguably the most common high-volume stamping process. It utilizes a single, complex die (the progressive die) containing multiple stations, each performing a distinct operation (e.g., punching, bending, coining) sequentially. Sheet metal, typically in coil form, is fed through the press, advancing incrementally ("progressing") from one station to the next with each stroke of the press. Technical Explanation:– Material Feed: A strip of metal coil is automatically fed into the press.

- Pilot Holes: Small holes are often punched in the initial stations to accurately locate the strip as it progresses through the die.

- Sequential Operations: Each station performs a specific task – cutting, bending, forming, drawing, embossing, etc.

- Carrying Web: The parts remain attached to the metal strip (carrier strip or carrying web) until the final station, where they are typically cut off.

*(Diagram illustrating a progressive die with multiple stations and material strip flow would be included here in a final web version)*Ideal Applications: Complex parts requiring multiple operations, high-volume production runs (typically >10,000 parts), parts for automotive, electronics, and appliance industries. Limitations: High initial tooling cost, longer lead times for tool development, less suitable for very deep drawn parts or extremely large components. Cost-Efficiency Analysis: While the initial tooling investment is significant, the high-speed, automated nature of progressive die stamping results in a very low per-part cost for large production volumes. Reduced labor and high material utilization contribute to its cost-effectiveness. Case Study: Automotive Industry Application– Part: Complex bracket for engine mounting.

- Challenge: Required multiple bends, holes, and formed features with tight tolerances (±0.05mm) at a volume of 1 million parts per year.

- Solution: A 15-station progressive die was designed and built. In-die sensors monitored critical dimensions.

- Outcome: Production rate of 80 parts per minute achieved, meeting volume requirements with a Cpk of 1.67, significantly reducing cost compared to previous multi-step processes.

Deep Draw Stamping

Deep drawing is a process where a sheet metal blank is radially drawn into a forming die by the mechanical action of a punch. It\’s considered "deep" drawing when the depth of the drawn part is equal to or greater than its diameter or smallest width dimension. This process is ideal for creating seamless, hollow shapes. Technical Parameters:– Draw Ratio: The ratio of the blank diameter to the punch diameter, a critical factor determining feasibility.

- Reduction: The percentage decrease in diameter during each drawing stage.

- Material Flow: Controlled flow of material into the die cavity is crucial to prevent wrinkling or tearing.

- Lubrication: Essential to reduce friction and prevent galling.

Material Considerations: Materials with high ductility and formability, such as certain grades of steel, aluminum, brass, and copper, are preferred. Material thickness and grain structure significantly impact the process. Tolerance Achievements: Can achieve tolerances of ±0.1mm, with tighter tolerances possible through secondary operations or specialized tooling. Wall thickness consistency can be challenging. Case Study: Electronics Industry Application– Part: Seamless aluminum enclosure for a portable hard drive.

- Challenge: Required a deep draw (depth > diameter), consistent wall thickness, and a smooth, cosmetic surface finish.

- Solution: Multi-stage deep drawing process using highly polished tooling and specialized lubricants. Annealing between stages was required.

- Outcome: Achieved the required depth and cosmetic finish. Tolerances of ±0.08mm were maintained. The seamless design improved product aesthetics and durability.

Four-Slide / Multi-Slide Stamping

Four-slide or multi-slide stamping uses specialized machinery equipped with four (or more) moving slides arranged typically at 90 degrees to each other. These slides carry tooling that acts on the material (usually wire or narrow strip) from multiple directions, often simultaneously. This allows for the creation of intricate, complex forms, particularly those involving bends in multiple planes. Technical Advantages:– Complex Geometries: Ideal for parts with intricate bends, twists, and forms that are difficult or impossible with conventional presses.

- Reduced Tooling Cost: Often requires less complex tooling compared to progressive dies for similar complex parts.

- Material Savings: Can utilize wire or narrow strip efficiently.

- Integrated Operations: Can incorporate tapping, welding, or assembly within the machine.

Production Speed: Typically slower than progressive die stamping but faster than manual or secondary operations for complex parts (30-200 parts/minute depending on complexity). Material Compatibility: Well-suited for wire forms and parts made from narrow metal strips, including spring steel, copper alloys, and stainless steel. Case Study: Medical Device Components– Part: Intricate spring clip for a medical diagnostic device.

- Challenge: Required multiple precise bends in different planes, made from biocompatible stainless steel wire, with high repeatability.

- Solution: A four-slide machine was tooled to form, cut, and heat-set the spring clip in a single, continuous process.

- Outcome: Consistent part geometry achieved with tolerances of ±0.05mm on critical dimensions. Production costs were 40% lower than the previous method involving manual bending.

Fine Blanking

Fine blanking is a specialized precision stamping process that produces parts with exceptionally smooth, square-sheared edges, often eliminating the need for secondary finishing operations like grinding or shaving. It uses a unique press and die design involving a V-ring (or stinger) impinging on the material around the part perimeter and counter-pressure. Precision Capabilities:– Edge Quality: Produces near-vertical, tear-free sheared edges over the entire material thickness.

- Flatness: Achieves superior part flatness compared to conventional blanking.

- Tolerances: Capable of holding very tight dimensional tolerances (±0.01mm to ±0.025mm).

Surface Finish: Results in excellent surface finish on the sheared edges (Ra 0.4-1.6 µm). Cost Comparison: Higher tooling and equipment costs than conventional blanking, but can be more cost-effective overall by eliminating secondary operations for high-precision parts. Case Study: Aerospace Application– Part: High-strength steel gear for an actuator mechanism.

- Challenge: Required perfectly square, smooth gear teeth edges for optimal performance and longevity, with tight tolerances on tooth profile and flatness.

- Solution: Fine blanking process was employed, producing net-shape gears directly from sheet stock.

- Outcome: Gear teeth met all dimensional and surface finish requirements without secondary machining. Part cost was reduced by 25% compared to the previous method of conventional blanking followed by shaving.

Transfer Die Stamping

Transfer die stamping is similar to progressive die stamping in that multiple operations occur sequentially, but instead of the parts remaining attached to a carrier strip, individual parts are transferred from one station to the next using mechanical "fingers" or a transfer system. This is often used for larger parts or parts that require operations on surfaces that would be inaccessible if attached to a strip. Process Explanation:– Blanking: Parts are typically blanked (cut from the sheet) in the first station.

- Transfer: Mechanical fingers grip the part and move it to the subsequent stations.

- Operations: Each station performs forming, drawing, piercing, or other operations.

*(Visual aid showing a transfer press with mechanical fingers moving a part between stations would be included here)*Production Volume: Suitable for medium to high production volumes, often bridging the gap between progressive dies and manual operations. Automation Integration: Highly automated process, often integrated with robotic loading and unloading. Case Study: Industrial Equipment Parts– Part: Large, deep-drawn housing for an industrial pump.

- Challenge: Part size and depth made progressive die stamping impractical. Required multiple forming and piercing operations.

- Solution: A transfer press with 8 stations was utilized. The system allowed for complex forming operations and piercing on multiple faces of the part.

- Outcome: Consistent production of the large housing achieved at a rate of 15 parts per minute. Eliminated several manual secondary operations, improving consistency and reducing labor costs.

III. Material Science in Metal Stamping

The selection of the right material is paramount in metal stamping, directly influencing the part\’s performance, manufacturability, and cost. Understanding material properties and their behavior during stamping is crucial for success. ### Material Selection Criteria

Choosing the optimal material involves balancing several factors: – Mechanical Properties: Strength (tensile, yield), hardness, ductility (formability), fatigue resistance, impact resistance.

- Physical Properties: Density (weight), electrical conductivity, thermal conductivity, magnetic properties.

- Chemical Properties: Corrosion resistance, biocompatibility.

- Manufacturability: Formability (drawability, bendability), weldability, machinability (for secondary operations).

- Cost: Raw material price, processing costs, availability.

- Environmental Considerations: Recyclability, environmental impact of extraction and processing.

| Material Properties Comparison Table: | — | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Low Carbon Steel | Moderate | Excellent | Poor | Low | Automotive panels, appliance housings, general use | |||||||

| High Carbon Steel | High | Poor | Poor | Low-Moderate | Springs, blades, wear parts | |||||||

| Stainless Steel | High | Moderate-Good | Excellent | Moderate-High | Medical devices, food equipment, automotive trim | |||||||

| Aluminum Alloys | Moderate-High | Good | Good | Moderate | Aerospace, automotive (lightweighting), electronics | |||||||

| Copper | Low | Excellent | Good | High | Electrical connectors, heat sinks | |||||||

| Brass | Low-Moderate | Excellent | Good | High | Decorative hardware, plumbing, connectors | |||||||

| Titanium Alloys | Very High | Poor-Moderate | Excellent | Very High | Aerospace, medical implants |

(Note: This is a simplified table. Actual properties vary significantly within each material category based on specific alloys and tempers.)### Common Materials and Their Properties

- Stainless Steel: Alloys of iron, chromium (min 10.5%), and often nickel. Known for excellent corrosion resistance. Austenitic grades (e.g., 304, 316) offer good formability but work-harden rapidly. Ferritic (e.g., 430) and Martensitic (e.g., 410) grades offer different combinations of strength, magnetism, and formability.

- Carbon Steel: Alloys of iron and carbon. Low carbon (<0.3%) steel is highly formable and weldable but has lower strength. Medium carbon (0.3-0.6%) offers balanced strength and ductility. High carbon (>0.6%) steel is strong and hard but brittle and difficult to form.

- Aluminum Alloys: Lightweight, good corrosion resistance, and high strength-to-weight ratio. Various series (e.g., 3xxx, 5xxx, 6xxx) offer different properties. 5xxx series is good for forming, while 6xxx series is heat-treatable for higher strength.

- Copper and Brass: Copper offers excellent electrical and thermal conductivity and good formability. Brass (copper-zinc alloy) is more machinable and offers good corrosion resistance. Both work-harden significantly.

- Exotic Materials: Includes titanium alloys (high strength-to-weight, corrosion resistance, biocompatible), nickel alloys (high temperature, corrosion resistance), and specialty alloys for specific demanding applications.

Material Testing and Validation Methods

Ensuring the incoming material meets specifications and the final part performs as expected requires rigorous testing: – Tensile Testing: Measures yield strength, ultimate tensile strength, and elongation (ductility).

- Hardness Testing: (Rockwell, Brinell, Vickers) Measures resistance to indentation, indicating wear resistance and strength.

- Formability Testing: (Erichsen cup test, Limiting Dome Height test) Assesses the material\’s ability to undergo deformation without failure.

- Chemical Analysis: Verifies alloy composition using techniques like spectroscopy.

- Microstructural Analysis: Examines grain size and structure, which affects properties and formability.

- Dimensional Inspection: Verifies final part geometry against specifications.

- Performance Testing: Simulates real-world conditions (e.g., fatigue testing, corrosion testing).

Adherence to industry standards (ASTM, ISO, SAE) and customer-specific requirements is crucial for material validation and quality assurance.

IV. Design Considerations for Metal Stamping Parts

Effective design is critical for producing functional, cost-effective, and reliable stamped metal parts. Designing with the stamping process in mind – known as Design for Manufacturability (DFM) – is essential. ### Design for Manufacturability (DFM)

DFM principles aim to simplify production, reduce costs, and improve quality. – Simplify Geometry: Avoid unnecessarily complex features. Combine multiple parts into a single stamping where possible.

- Material Orientation: Consider material grain direction, especially for bends in high-strength materials, to prevent cracking. Bends parallel to the grain are weaker.

- Feature Placement: Avoid placing features like holes or slots too close to bends or edges, as this can cause distortion.

- Standardize: Use standard hole sizes, bend radii, and material thicknesses whenever possible to reduce tooling costs.

- Burr Direction: Specify acceptable burr direction, as stamping inherently creates a burr on one side.

Common Design Pitfalls:– Sharp internal corners (lead to stress concentrations and tool wear).

- Bends with zero radius (impossible to achieve, leads to cracking).

- Features too close together.

- Tolerances tighter than necessary.

- Designing parts requiring excessive material stretching.

Tolerance Capabilities and Limitations

Understanding achievable tolerances is vital for realistic design. – Standard Tolerances: Typically ±0.1mm to ±0.2mm for general stamping.

- Precision Tolerances: Can range from ±0.025mm to ±0.05mm with specialized processes like fine blanking or high-precision progressive dies.

- Factors Affecting Tolerances: Material type and thickness, part complexity, tool condition, press accuracy, process type.

- Cost Implications: Tighter tolerances significantly increase tooling costs and may require slower production speeds or secondary operations.

- GD&T: Geometric Dimensioning and Tolerancing should be used appropriately to define critical functional requirements without over-tolerancing non-critical features.

Surface Finish Requirements

Surface finish is important for aesthetics, friction, wear, and coating adhesion. – Measurement: Typically measured as Ra (Roughness Average) in µm or µin.

- Stamping Finish: Standard stamping produces finishes related to the raw material and tooling condition. Fine blanking offers superior edge finishes.

- Post-Processing: Secondary operations like tumbling, polishing, plating, or painting can achieve specific surface finishes.

- Specification: Clearly define required surface finish on drawings, specifying measurement methods and locations.

CAD/CAM Integration

Modern stamping relies heavily on digital tools. – CAD Software: Used for part design (e.g., SolidWorks, CATIA, NX). DFM analysis tools within CAD software can identify potential stamping issues early.

- Simulation Software: (e.g., AutoForm, Pam-Stamp) Simulates the stamping process, predicting material flow, thinning, wrinkling, and springback. This reduces the need for costly physical trials.

- CAM Software: Used to program the CNC machines that create the stamping dies.

- Digital Twin: Creating a virtual replica of the stamping process allows for real-time monitoring, analysis, and optimization.

V. Industry Applications of Metal Stamping Parts

Metal stamping parts are integral components in nearly every manufacturing sector. ### Automotive Sector

- Applications: Body panels, chassis components, brackets, engine parts (gaskets, heat shields), exhaust components, seating structures, electrical connectors, EV battery enclosures and busbars.

- Requirements: High volume, cost-effectiveness, durability, crashworthiness, weight reduction (using high-strength steels and aluminum), tight tolerances for assembly.

- Case Study: EV Battery Components: Progressive die stamping used to produce intricate copper and aluminum busbars for EV battery packs, requiring high electrical conductivity and precise geometry for automated assembly.

Aerospace and Defense

- Applications: Structural components (ribs, brackets), engine components, fasteners, clips, electronic enclosures, ordnance components.

- Requirements: High strength-to-weight ratio (titanium, high-strength aluminum, specialty alloys), extreme precision, high reliability, stringent quality control and traceability, resistance to extreme temperatures and corrosion.

- Case Study: Lightweight Structural Components: Fine blanking and specialized forming techniques used to create complex, lightweight brackets from aerospace-grade aluminum alloys, meeting strict weight and strength specifications.

Electronics and Telecommunications

- Applications: Connectors, terminals, EMI/RFI shields, heat sinks, lead frames, chassis, brackets, mobile phone components (frames, internal brackets).

- Requirements: Miniaturization, high precision, excellent electrical conductivity (copper alloys), good thermal management, cost-effectiveness for high volumes, EMI shielding effectiveness.

- Case Study: 5G Infrastructure Components: Micro-stamping processes used to produce tiny, high-precision connectors and shields for 5G base station equipment, requiring tolerances in the micron range.

Medical Devices

- Applications: Surgical instruments (forceps, clamps), implantable components (pacemaker casings, orthopedic implants – often requiring secondary machining), diagnostic equipment housings and internal components, drug delivery device parts.

- Requirements: Biocompatibility (stainless steel, titanium), high precision, cleanliness (cleanroom manufacturing), smooth surfaces, burr-free edges, stringent quality control and validation (FDA regulations).

- Case Study: Implantable Device Components: Deep drawing used to create seamless titanium casings for pacemakers, ensuring biocompatibility and hermetic sealing. Secondary laser welding and finishing were required.

Consumer Products

- Applications: Appliance housings and internal parts (washers, dryers, refrigerators), hardware (hinges, brackets, fasteners), tools, cookware, lighting fixtures.

- Requirements: Cost-effectiveness, high volume, aesthetic appeal (surface finish, coatings), durability, safety standards compliance.

- Case Study: Home Appliance Components: High-speed progressive die stamping used to produce millions of stainless steel drum components for washing machines, balancing cost, durability, and corrosion resistance.

VI. Quality Control and Testing

Maintaining consistent quality is critical in metal stamping, especially for high-volume or safety-critical applications. ### In-Process Inspection Methods

- Vision Systems: Automated cameras inspect parts on the press or conveyor for dimensional accuracy, surface defects, and feature presence.

- In-Die Sensors: Sensors embedded within the stamping die monitor critical parameters like material position, forming pressure, or part ejection in real-time.

- Statistical Process Control (SPC): Operators periodically measure parts and plot data on control charts to monitor process stability and identify trends before parts go out of specification.

- Laser Measurement: Non-contact laser systems provide rapid dimensional checks.

Post-Production Testing

- Coordinate Measuring Machines (CMM): Provide highly accurate 3D measurements of complex geometries.

- Optical Comparators: Project a magnified silhouette of the part for visual inspection against a template.

- Hardness Testers: Verify material hardness after forming.

- Material Analysis: Confirm alloy composition and check for contamination.

- Functional Testing: Test the part in its intended assembly or application (e.g., fatigue testing, load testing, electrical conductivity testing).

Industry Standards and Certifications

- ISO 9001: General quality management system standard.

- IATF 16949: Specific quality standard for the automotive industry.

- AS9100: Quality standard for the aerospace industry.

- ISO 13485: Quality standard for medical devices.

- Documentation: Maintaining comprehensive records (material certs, inspection reports, process parameters, traceability data) is crucial for compliance and quality assurance.

VII. Cost Factors and Economic Considerations

Understanding the cost structure of metal stamping is essential for project planning and supplier negotiation. ### Tooling Investment Analysis

- Initial Cost: Stamping dies, especially complex progressive or transfer dies, represent a significant upfront investment (ranging from thousands to hundreds of thousands of dollars).

- Lifetime Cost: Includes initial cost plus maintenance, repair, and potential modification costs over the tool\’s life (typically hundreds of thousands to millions of cycles).

- Amortization: Tooling cost is typically amortized over the expected production volume, heavily influencing the per-part cost.

- Tool Maintenance: Regular maintenance (sharpening, cleaning, component replacement) is crucial for maintaining part quality and maximizing tool life.

Production Volume Break-Even Analysis

- Break-Even Point: The production volume at which the total cost of stamping (including amortized tooling) becomes lower than alternative methods (e.g., machining, fabrication).

- Comparison: Stamping is generally most cost-effective for medium to high volumes (typically >10,000 – 50,000 parts, depending on complexity).

- ROI Calculation: Requires careful analysis of tooling costs, per-part costs, production rates, and comparison with alternatives.

Value Engineering Opportunities

- Design Optimization: Simplifying designs, standardizing features, and designing for efficient material nesting can significantly reduce costs.

- Material Selection: Choosing the most cost-effective material that meets performance requirements.

- Secondary Operation Elimination: Designing parts that require minimal or no secondary operations (e.g., using fine blanking for smooth edges).

- Process Optimization: Collaborating with the stamper to optimize the process for speed and material utilization.

VIII. Future Trends in Metal Stamping

The metal stamping industry is continuously evolving, driven by technological advancements and market demands. ### Industry 4.0 Integration

- Smart Presses: Presses equipped with sensors and connectivity for real-time monitoring, predictive maintenance, and automated adjustments.

- IoT: Connecting equipment throughout the production line for data collection and analysis, enabling process optimization.

- Simulation & Digital Twin: Increased use of advanced simulation for process design and virtual commissioning. Digital twins provide real-time insights into physical operations.

- Automation & Robotics: Greater use of robots for material handling, part transfer, inspection, and packaging.

Sustainable Manufacturing Practices

- Material Efficiency: Advanced nesting software and process optimization to minimize scrap.

- Energy Efficiency: Development of more energy-efficient servo-driven presses instead of traditional hydraulic or mechanical presses.

- Lubricant Reduction: Dry lubricants or minimal quantity lubrication (MQL) systems to reduce environmental impact.

- Recycling: Improved processes for recycling scrap metal.

Advanced Materials Development

- High-Strength Steels (AHSS/UHSS): Continued development and adoption, particularly in automotive for lightweighting, requiring specialized tooling and process control.

- Advanced Aluminum Alloys: New alloys offering improved strength and formability.

- Composite Stamping: Exploring techniques to stamp metal-composite hybrid materials.

- Additive Manufacturing for Tooling: Using 3D printing to create complex die components or prototypes more quickly.

IX. Conclusion

Metal stamping parts are fundamental to modern manufacturing, offering a powerful combination of precision, speed, and cost-effectiveness for producing components from sheet metal. Successfully leveraging this technology requires a deep understanding of the various processes (progressive, deep draw, fine blanking, etc.), careful material selection based on scientific principles, adherence to robust design-for-manufacturability guidelines, and rigorous quality control. Choosing the right stamping process and manufacturing partner involves considering part complexity, production volume, material requirements, and cost targets. By understanding the technical nuances, cost drivers, and industry trends outlined in this guide, engineers, designers, and procurement professionals can optimize their designs, make informed sourcing decisions, and ultimately create better, more cost-effective products. The future of metal stamping lies in the integration of digital technologies (Industry 4.0), the adoption of sustainable practices, and the ability to process increasingly advanced materials. Staying abreast of these developments will be key to maintaining a competitive edge in the dynamic world of manufacturing. ## Contact Us

📧 Email us: [email protected]🌐 Visit: https://primecustomparts.comGet a free quote, custom tool configuration, and fast delivery worldwide. Every order comes with setup support. – – – – – –