Tolerances and Surface Finishes in Plastic Injection Molding: What Engineers Must Know?

Designing injection-molded plastics requires understanding tolerances and finishes—these define functionality, aesthetics, cost, and manufacturability.

Knowing standard vs. precision tolerances, SPI surface grades, cosmetic vs. functional finishes, and inspection protocols helps engineers reduce defects and optimize designs. This guide walks through each topic with best practices.

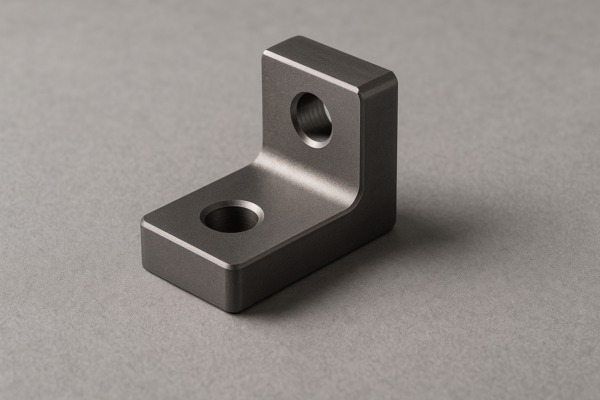

Standard tolerances: ±0.1 mm vs. precision grades

What are standard tolerances?

Typical commercial injection-molded parts use tolerances of ±0.1 mm to ±0.2 mm (±0.004″–0.008″), in line with ISO 20457 and ANSI Y14.5 guidelines. At Prime, ±0.1 mm is routine.

When are precision tolerances needed?

High-precision parts (±0.05 mm or better) require hardened molds, tight control, and consistent resin selection:

- Follow high-precision classes per ISO 286‑2

- Common in medical fittings, micro-optics, and snap-fits

- Factors: resin class (e.g., PC vs. PP), wall thickness, molding process stability

Prime uses Statistical Process Control (SPC) and CMM inspections to maintain precision.

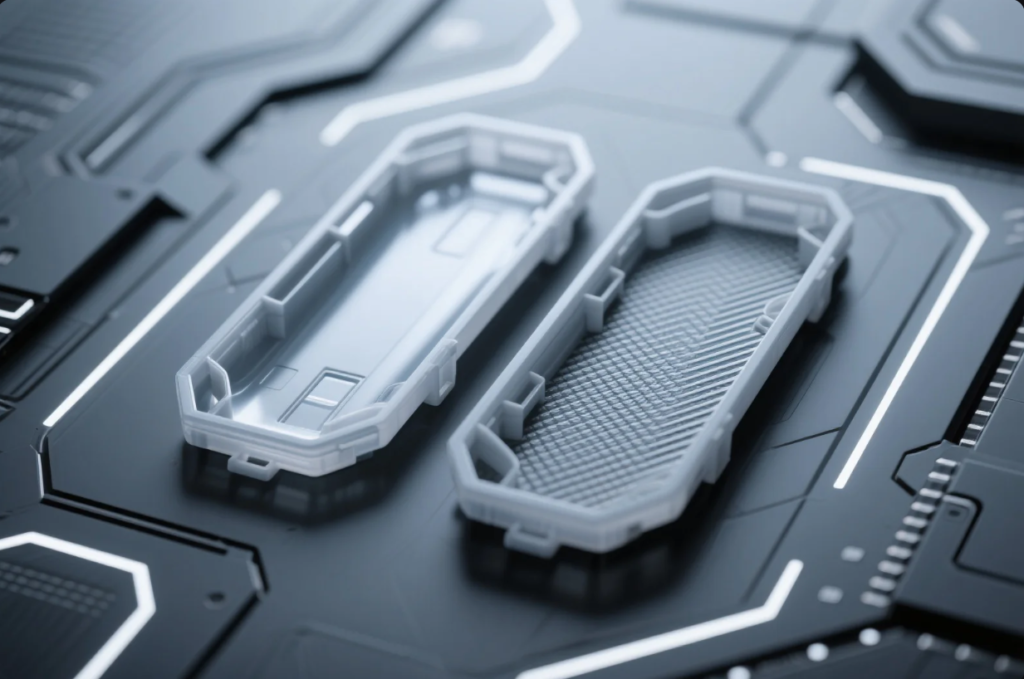

SPI surface finish classifications: A1–D3 explained

The Society of the Plastics Industry (SPI) defines eight standard mold surface textures:

| Grade | Finish Description | Typical Use |

|---|---|---|

| A1 | Mirror-polished | Optical lenses, luxury electronics |

| A2 | Fine gloss | High-end consumer devices |

| B1 | Soft gloss | Automotive instrument panels |

| B2 | Semi-matte finish | Appliance bezels |

| C1 | Satin/matte | Outdoor enclosures |

| C2 | Light texture | Industrial interfaces |

| D1 | Coarse pebble (\~60 µm) | Hand grips, tools |

| D3 | Heavy texture (\~150 µm) | Flooring, safety surfaces |

Prime collaborates with SPI-certified moldmakers to deliver consistent textures. Learn more via the SPI guide.

Cosmetic vs. functional finishes: how to select

Cosmetic finishes

- Gloss (A-grade) offers shine but highlights blemishes

- Matte/texture (B–C grades) hides defects and improves wear

- Cost increases with finish quality due to molding and polishing needs

Functional finishes

- Textured finishes (D-grades) provide grip and conceal wear

- Micro-texture improves paint adhesion and friction management

- Soft-touch coatings (TPE, silicone) add tactile quality and require mold inserts or spray processes

Prime uses texture inserts or direct mold machining, sourcing from partners like Mold‑Masters.

Inspection protocols for warping, flash, sink marks

Dimensional inspection

- CMM measures dimensional accuracy and form errors

- Optical comparators check profiles and detect flash

Visual & consultant checks

- Inspect for flash, burrs, and gate vestige

- Identify sink marks and surface depressions

- Detect warpage using jigs, fixtures, and CAD comparisons

Advanced techniques

- 3D scanning compares full-form to CAD

- ZIF stacking measures dimensional consistency in assembled parts

- SPC tracks key dimensions and defect trends

Prime builds inspection into first batch protocols, applying ISO 9001 quality management.

FAQs

1. What tolerance range is standard?

±0.1 mm is typical; ±0.05 mm or better requires precision molds and SPC.

2. What does SPI B1 mean?

B1 provides a semi-gloss finish—ideal for instruments and visible surfaces.

3. Gloss or matte? Which to choose?

Gloss for aesthetics; matte for durability and hiding imperfections.

4. How is warpage measured?

Using dimensional jigs, 3D scanning, or CMM/optical devices.

5. Can Prime meet tight specs?

Yes. We deliver precision tolerances and certified surface finishes, with full inspection documentation.

Contact Us

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Conclusion

Tolerances and surface finishes are foundational to molding success. Align your part requirements with tolerance precision, surface textures, and inspection plans to improve reliability and cost-efficiency.

Partner with Prime for expert guidance, certified finish quality, and robust QC systems—ensuring your parts meet design, aesthetic, and functional demands.