Top 10 Custom Metal Mold Manufacturers in 2025 for Industrial Projects: Who’s Leading in Quality & Delivery?

Choosing the wrong mold supplier leads to delays, defects, and lost profits.

This 2025 guide introduces the top 10 custom metal mold manufacturers trusted for industrial-grade projects. We cover companies with strong global presence, ISO certifications, advanced machining, and fast delivery for injection, stamping, and die casting molds.

Whether you’re sourcing from China, Europe, or North America, this list helps you make the right call on your next tooling partner.

Who is the best mold maker in China?

China dominates the global mold market—but only a few stand out for industrial-grade quality.

The best mold makers in China combine advanced CNC/EDM facilities, ISO-certified systems, export expertise, and strong English support. Leaders include Shenzhen Silver Basis, Sino Mould, and Shandong Prime International Trade Co., Ltd..

Recommended Mold Makers (China, 2025)

| Company Name | Strengths |

|---|---|

| Prime (Shandong) | Custom metal molds, fast delivery, ISO |

| Silver Basis | Large-scale auto molds, export-ready |

| Sino Mould | Injection mold R\&D, export-focused |

| Abery Mold & Plastics | Mold + plastic part service |

| Djmolding | Low-cost prototype tooling |

Prime stands out for its full in-house production of CNC, stamping, casting, and MIM molds—combined with strong export packaging and DFM analysis.

How much does a custom mold cost?

Tooling cost depends on complexity, metal type, and expected volume.

A custom metal mold can range from \$2,000 for simple aluminum tools to over \$50,000 for multi-cavity hardened steel dies. Die casting and MIM molds tend to be more expensive due to high-pressure cycles and tighter tolerances.

Average Mold Costs (USD, 2025)

| Mold Type | Cost Range (USD) | Application |

|---|---|---|

| Stamping Die | \$3,000–\$20,000 | Sheet metal forming |

| Die Casting Mold | \$8,000–\$40,000 | High-pressure metal parts |

| Injection Mold | \$5,000–\$30,000 | Plastic/metal-injection molding |

| MIM Mold | \$10,000–\$50,000 | Micro-sized precision metal parts |

Prime offers flexible payment terms and early DFM reviews to keep costs predictable and reduce revisions.

Try Xometry’s mold cost estimator for a rough guide.

Are mold makers in demand?

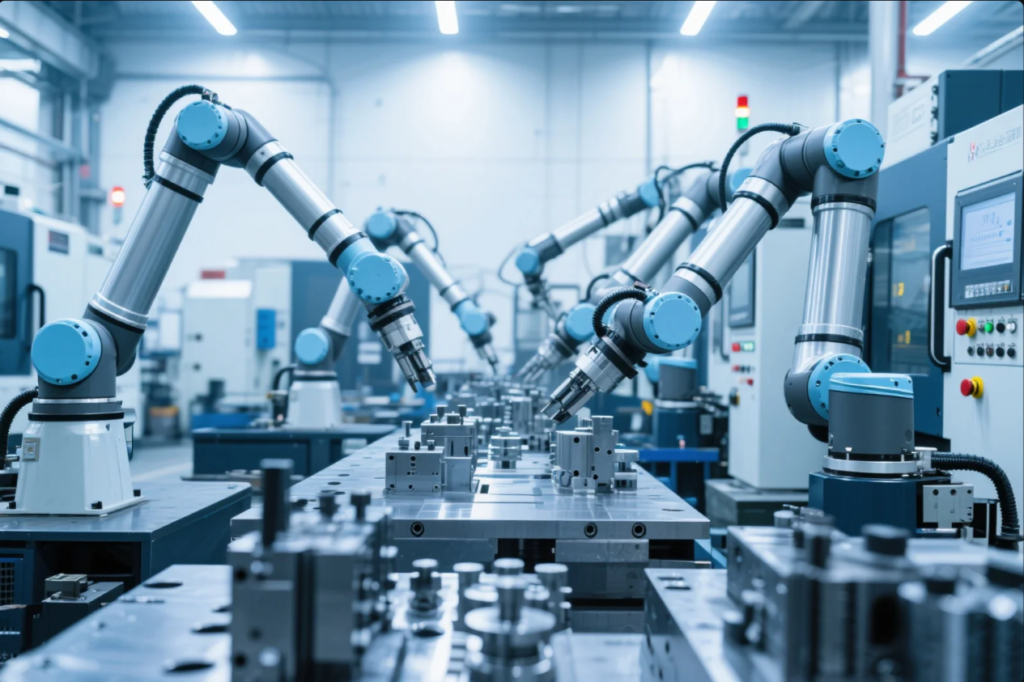

With the growth of EVs, automation, and smart devices, demand for tooling is surging.

Yes, mold makers are in high demand across automotive, aerospace, medical, and electronics sectors. As tooling gets more complex, skilled mold technicians, CNC programmers, and tool designers are increasingly needed.

Tooling Demand Outlook (2025–2030)

| Industry | Reason for Demand |

|---|---|

| Automotive | New EV platforms, lighter die cast parts |

| Medical | Growth in MIM components, micro-molds |

| Consumer Devices | Multi-cavity tools, rapid market cycles |

| Aerospace | Titanium casting molds, insert tools |

Read more at MoldMaking Technology.

Prime invests heavily in talent and machine upgrades to meet global mold orders with fast turnaround and QA reliability.

What are the different types of Moulds?

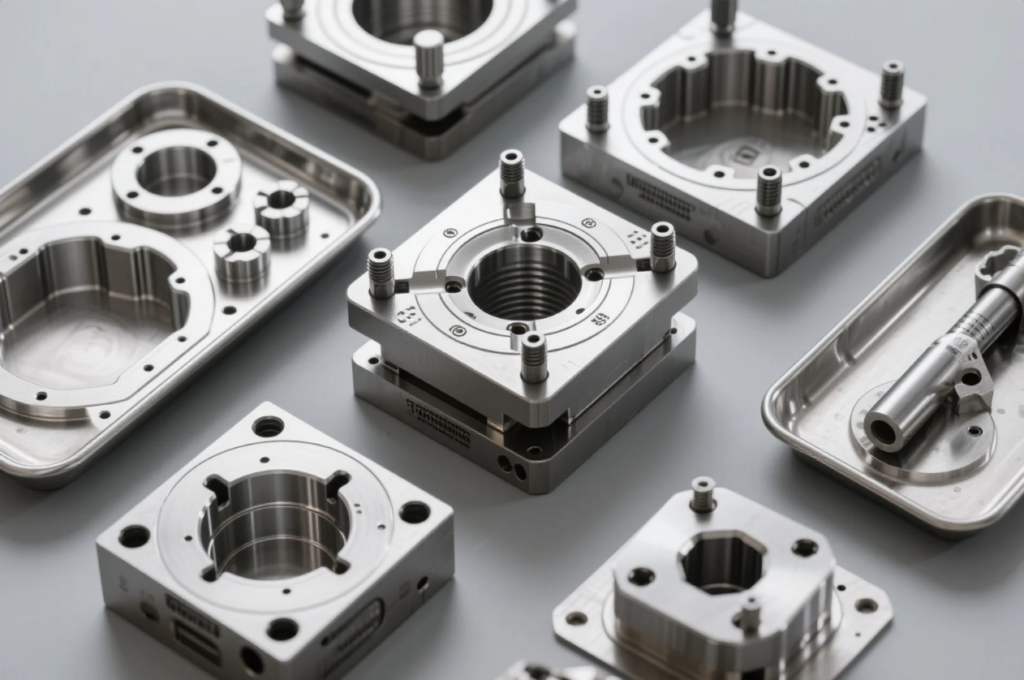

Not all molds are created equal—each type fits a specific forming process.

Common industrial mold types include stamping dies, die casting molds, metal injection molds (MIM), and prototype tools. Each one varies in cost, life cycle, and material requirements.

Common Mold Types

| Mold Type | Used For | Material Often Used |

|---|---|---|

| Stamping Dies | Sheet metal forming | SKD11, D2 tool steel |

| Injection Molds | Plastic or MIM parts | P20, H13, S7 steel |

| Die Casting Molds | Aluminum, zinc casting | H13, SKD61 |

| Rapid Prototyping | Low-volume testing | 7075 aluminum, epoxy molds |

At Prime,Custom Metal Mold Manufacturers, we manufacture all four types in-house, with full CMM inspection and custom packaging for global delivery.

For definitions, see Wikipedia’s molding tool overview.

FAQs

Q1: Which mold maker offers fastest lead times?

A1: Prime delivers soft aluminum tools in 10 days and hardened steel in 25 days.

Q2: What quality checks are done on custom molds?

A2: 3D coordinate inspection (CMM), hardness testing, surface finish QC, and trial reports.

Q3: Can I modify my mold later?

A3: Yes. Prime supports design changes, insert swaps, and cavity additions.

Q4: Do you export molds worldwide?

A4: Absolutely. We ship molds to over 30 countries with wooden crate and vacuum packaging.

Q5: Can I get a DFM review before ordering?

A5: Yes. Prime provides free DFM review and optimization suggestions before production.

Contact Information

Looking for a reliable custom mold partner for your industrial project?

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

Our Mold Services Include:

- Custom metal mold design and fabrication

- MIM, die cast, injection and stamping mold options

- ISO 9001 certified QA process

- Global delivery and multi-language support

Choose Prime for precision tooling, fast delivery, and world-class service.

With 20+ years of experience and full in-house production, we help industrial clients around the world turn ideas into reliable molds.