Top 10 Custom Metal Molds for Automotive Applications in 2025?

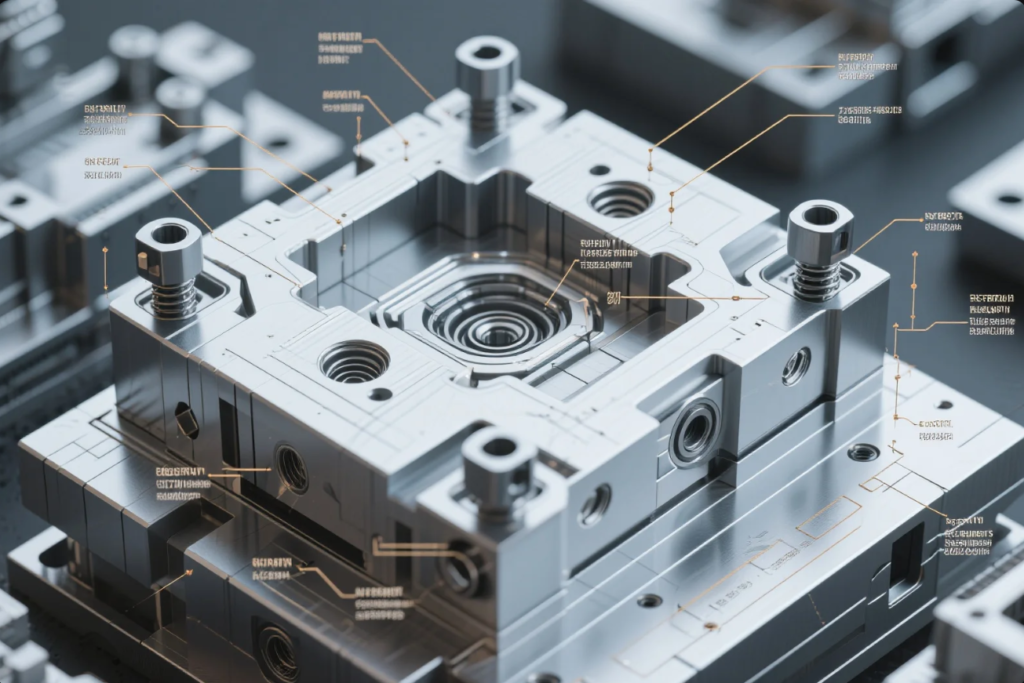

Auto makers face rising demands for precision parts. Poor molds waste material and time.

Metal molds in automotive production must withstand pressure, heat, and volume. The wrong mold design causes defects and delays.

Let’s explore 2025’s most reliable custom molds. I’ll also share how our ISO-certified shop helps clients avoid risks.

What is the future of metal injection molding?

Metal injection molding (MIM) is becoming essential in modern vehicle manufacturing. As parts get smaller and more complex, traditional machining methods struggle to deliver accuracy at scale.

MIM allows manufacturers to produce high-strength, highly detailed parts at reduced cost. The method merges the accuracy of CNC with the scalability of plastic injection.

MIM Trends to Watch in 2025

As we move into 2025, several major trends are redefining the way custom molds are designed for MIM:

| Trend | Description |

|---|---|

| Miniaturization | Automotive sensors and connectors are shrinking; molds must support tiny cavities |

| Material Innovation | Powder blends now include titanium, nickel alloys, and magnetic steels |

| Smart Molding | IoT-enabled molds optimize temperature, pressure, and injection speed |

| Sustainability Focus | Less waste, more recycled input materials |

| Functional Integration | Parts combine multiple functions into one moldable shape |

Our factory regularly produces MIM-ready molds for fuel injection systems, turbocharger actuators, and EV battery enclosures. One North American customer used our custom CNC injection mold service and improved production speed by 45%.

Want to learn more about the MIM process? Visit the Wikipedia page for metal injection molding.

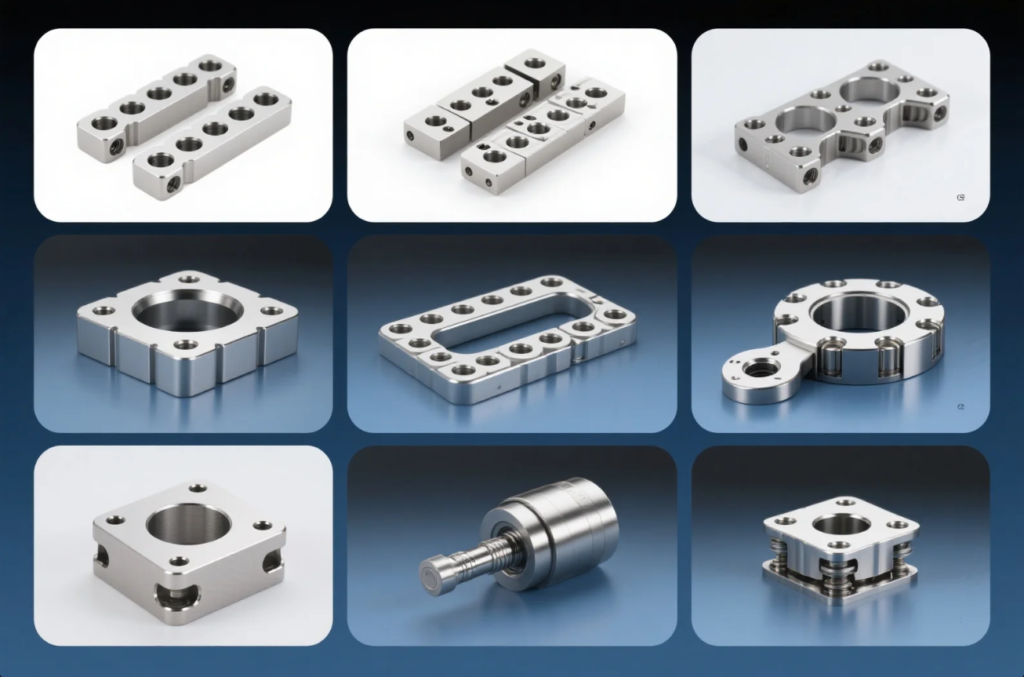

What Moulds are used in metal casting?

Not all casting molds are created equal. Each type offers different advantages for different part geometries, volumes, and metals.

Metal casting molds fall into several categories: sand molds, permanent molds, die molds, shell molds, and investment molds.

Deep Dive: Types and Applications

| Mold Type | Description | Best Use Case |

|---|---|---|

| Sand Mold | Made from compacted sand, low cost, high flexibility | Large engine blocks, testing parts |

| Permanent Mold | Reusable steel or cast iron molds for simple, repeatable parts | Gear housings, pulleys |

| Die Casting Mold | Precision tool steel molds under high pressure | Complex, high-volume parts like brackets |

| Shell Mold | Thin-layer sand molds with excellent surface finish | Valves, impellers |

| Investment Mold | Ceramic molds built around wax patterns for extreme detail | EV cooling channels, aerospace parts |

We support all five mold types in-house. Using advanced CAD/CAM, we help customers select or develop custom molds optimized for casting success. For an in-depth guide, see this article on types of metal casting molds from EngineeringClicks.

What metal is widely used for casting?

Material choice is just as important as mold design. Each metal alloy has unique thermal, mechanical, and fluidity properties that affect casting behavior.

Aluminum is by far the most common choice in the automotive sector due to its low weight, strength, and corrosion resistance.

Most Used Casting Metals in 2025

| Metal | Strengths | Limitations | Common Parts |

|---|---|---|---|

| Aluminum | Lightweight, easy to machine, corrosion-resistant | Lower hardness, requires precise mold design | Transmission covers, mirror arms |

| Cast Iron | Excellent vibration damping, affordable | Brittle, very heavy | Brake drums, exhaust manifolds |

| Steel | Superior toughness, good weldability | High melting point, tooling wear | Suspension parts, structural frames |

| Zinc | Fluid, detailed, low-cost | Poor high-temp resistance | Interior trims, electronic housings |

| Magnesium | Ultra-lightweight | Flammable in dust form, less durable | Gear housings in e-mobility systems |

Visit Ryobi Group’s aluminum die casting or Dynacast zinc casting page for real-world examples. For a foundational overview, refer to the aluminum casting alloy Wikipedia page.

What four types of molds are used in casting?

Choosing the wrong mold increases defect rates, rework, and cycle time. That’s why understanding the four key mold types is essential.

The main molds include sand casting, permanent mold casting, die casting, and investment casting. Each has its own role depending on batch size and finish requirements.

Mold Comparison Chart

| Type | Surface Finish | Dimensional Accuracy | Setup Cost | Volume Suitability |

|---|---|---|---|---|

| Sand Casting | Rough | Low | Low | Prototypes or short runs |

| Permanent Molding | Smooth | Moderate | Medium | Mid-volume parts |

| Die Casting | Very smooth | High | High | High-volume production |

| Investment Casting | Smooth, detailed | Very high | High | Precision, low-volume |

We helped a client in Germany switch from sand molds to permanent steel molds for differential housings. They cut tooling costs by 22% and improved their casting defect rate by over 30%. You can explore investment casting from Hitchiner or die casting basics via Wikipedia.

FAQs

1. What is the best mold for mass automotive production?

Die casting molds are ideal. They deliver fast cycle times, tight tolerances, and smooth surfaces.

2. What if I want both plastic and metal parts in the same design?

We support hybrid molds that combine metal bases with plastic inserts for functional integration.

3. What CAD formats do you accept for mold designs?

We accept STEP, IGES, SolidWorks, and DXF formats. Our engineers also help with DFM optimization.

4. Do your molds support automation compatibility?

Yes. We design all molds with robotic pick-and-place clearance, cooling channels, and ejection compatibility.

5. Can you support ITAR or aerospace-grade components?

We can partner with certified facilities for ITAR. All our molds follow ISO 9001 and RoHS standards.

Conclusion

Top casting results come from the right mold. Prime ensures speed, strength, and consistency.

Ready to simplify your custom mold sourcing? At Prime, we offer free consulting and instant quotes. Our ISO-certified production lines ensure stable quality and fast delivery.

📞 Email: [email protected]

🌐 Website: https://primecustomparts.com

Let us help you engineer the future—one mold at a time.