Top 10 Custom Welding Parts Manufacturers for Industrial Projects in 2025?

Late deliveries. Poor weld strength. Misaligned joints. These issues ruin industrial projects.

Top welding parts manufacturers in 2025 offer certified quality, precise joints, and fast, export-ready service.

Keep reading to discover which suppliers lead this year and how to pick the best welding parts provider for your business.

What is the job outlook for the next 10 years for welding?

Many think automation will kill welding jobs. But data shows otherwise.

According to the U.S. Bureau of Labor Statistics, welding jobs are expected to grow steadily through 2032.

Welding remains essential in manufacturing, shipbuilding, and infrastructure—industries not easily automated. As baby boomers retire, demand for skilled welders is rising.

So, global demand for custom welding parts and fabricated assemblies continues to grow.

What is the future of the welding industry?

The future of welding is not about replacement—it’s about transformation.

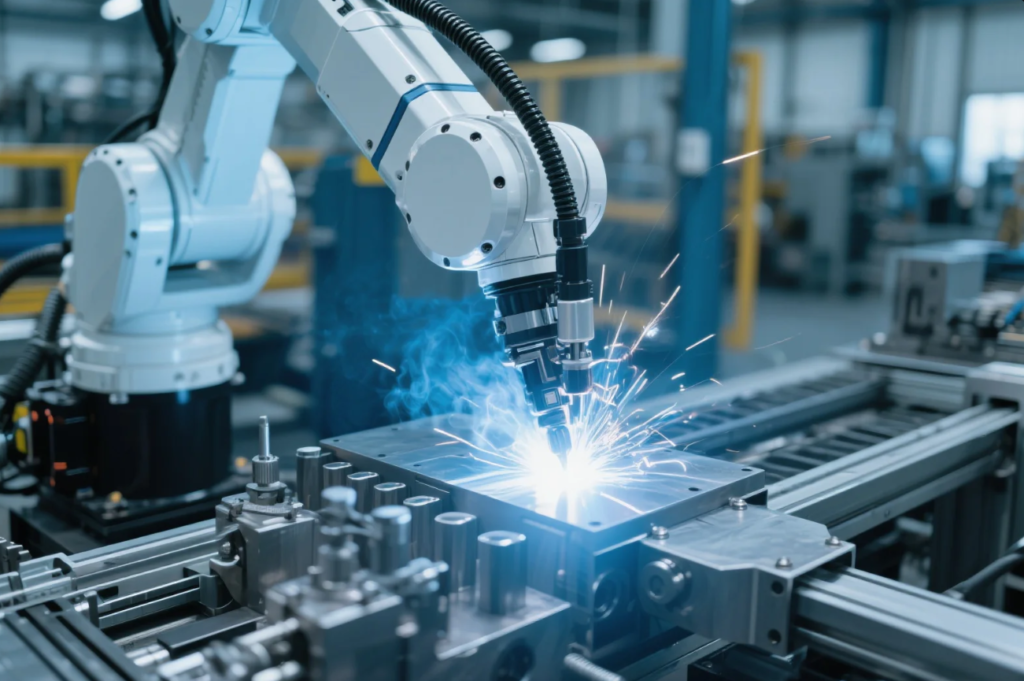

Welding is evolving with robotics, automation, and smart monitoring.

Major trends include:

- Robotic welding for repeatability

- AI-based inspection for defect detection

- Laser and friction stir welding for precision

- Lightweight material welding for EV and aerospace

Welding Productivity Magazine offers updates on new tech shaping the industry.

At Prime, we combine manual, MIG/TIG, and robotic welding to serve a wide range of industries—from machinery to heavy-duty frames.

Who is the largest manufacturer of welding equipment?

Knowing who leads equipment supply helps when matching your part specs.

Lincoln Electric is the largest welding equipment manufacturer globally, followed by Miller and ESAB.

They support high-end robotic systems and manual welding tools used in auto, aerospace, and heavy industry.

At Prime, we use Lincoln and Miller machines for MIG and TIG processes, ensuring consistent arc quality for every weld seam.

What type of welding is most in demand?

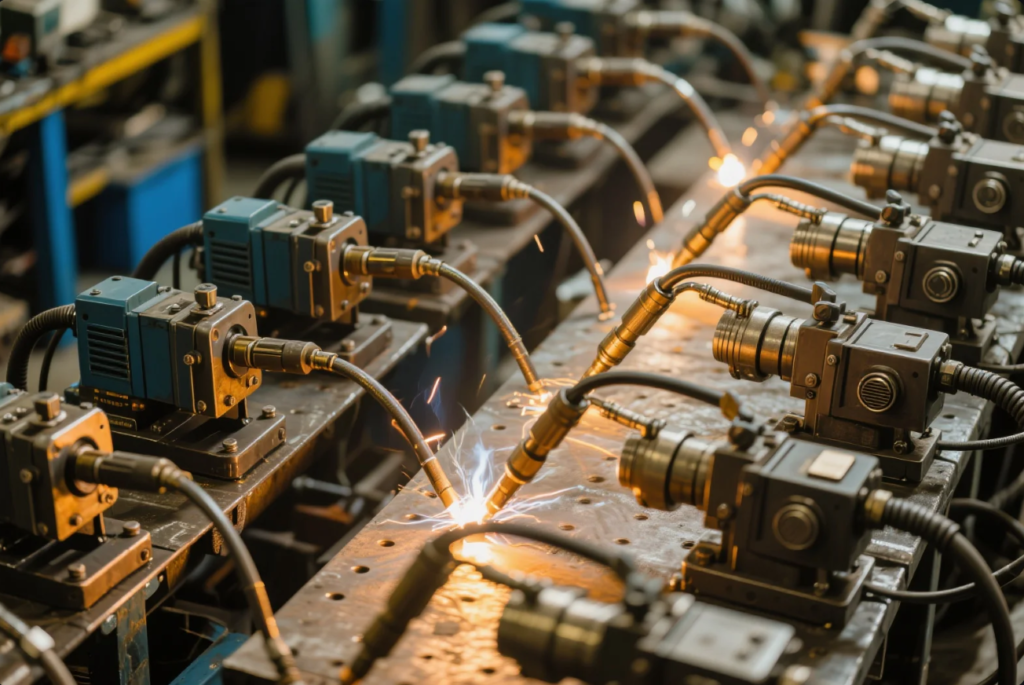

Not all welds are created equal. Demand varies by industry and part type.

MIG welding (Gas Metal Arc Welding) is the most in-demand process for industrial fabrication.

It balances speed, strength, and automation potential.

| Welding Type | Best Use Cases | Pros | Cons |

|---|---|---|---|

| MIG | Auto frames, machinery, large parts | Fast, consistent, easy to automate | Less precision for thin parts |

| TIG | Food equipment, medical parts | Precise, clean, aesthetic | Slower, needs skill |

| Spot Resistance | Appliances, sheet metal | Fast for thin metal joining | Only works on clean overlaps |

| Robotic Welding | Mass production | Speed + repeatability | High setup cost |

Prime offers MIG, TIG, spot, and robotic welding with optional surface finishes and dimensional reports. We meet ISO and custom weld testing standards.

Top 10 Custom Welding Parts Manufacturers

Choosing a supplier is more than just who welds—it’s about who delivers consistent value.

| Manufacturer | Country | Key Strengths |

|---|---|---|

| Shandong Prime | China | MIG/TIG/robotic welds, ISO-certified, export-ready |

| Murray Steel Products | UK | Structural steel, custom welding frames |

| Mayville Engineering Company (MEC) | USA | Fabricated weldments for heavy machinery |

| Harsco Rail | USA | Complex assemblies with weld + paint |

| Kloeckner Metals | USA | Welded parts + distribution services |

| Valk Welding | Netherlands | Robotic welding system integration |

| Nissin Manufacturing | Japan | Precision TIG welding for auto parts |

| S\&B Metal Products | USA | Full-service fabrication, robotic welds |

| G.James Group | Australia | TIG + architectural metal work |

| Fip Mec Srl | Italy | MIG welding for industrial applications |

FAQs

Q1: How do I know if a welding part meets quality standards?

Look for ISO 3834 certification, visual inspection reports, and weld penetration test data.

Q2: What files should I provide for custom welding orders?

Ideally 2D CAD files with weld symbols + 3D models in STEP/STP. Prime also offers drawing support if needed.

Q3: Can I combine welding with CNC or stamping?

Yes. Prime offers integrated stamping + welding + machining for industrial assemblies.

Q4: What’s the typical lead time?

Standard lead time: 15–30 days. We support urgent orders with flexible batch sizes.

Q5: Do you support coating and surface treatment?

Yes. Powder coating, galvanizing, and painting are available upon request.

Contact Us

Need high-quality welded assemblies with certified precision and fast delivery?

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Prime delivers:

- MIG, TIG, spot, and robotic welding

- Customizable solutions for global clients

- Free consultation and quote within 24 hours

Start your industrial project with a welding partner that guarantees quality, communication, and cost-efficiency.