Top 10 Engineering Plastics Used in Industrial‑Grade Plastic Components

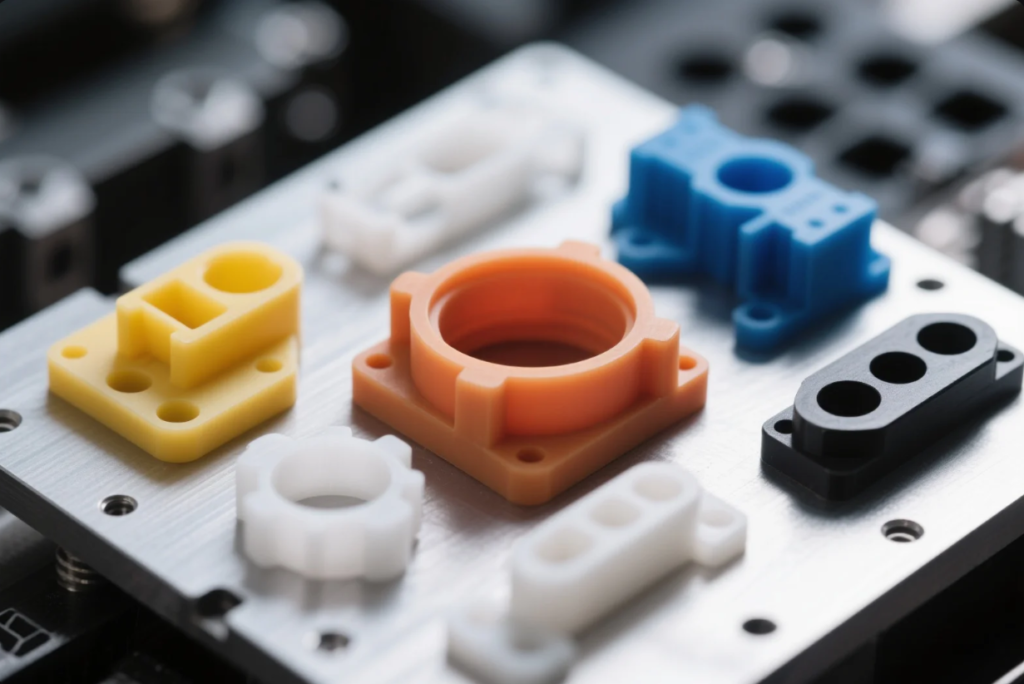

Selecting the right engineering plastic is a pivotal step for product designers, engineers, and procurement managers. The material choice directly affects functionality, lifespan, cost, manufacturability, and compliance. This guide dives deep into the top 10 plastics used in industrial-grade parts, exploring their unique traits, performance profiles, application scenarios, and real-world decision-making. Whether you’re designing structural assemblies, electronic housings, or fluid-handling devices, you’ll find clarity and relevance here.

ABS, Nylon, POM, PC, and More: What Makes Each Plastic Unique?

Here are the top 10 most widely used engineering plastics, with essential characteristics and real-world applications:

| Plastic | Key Traits | Common Industrial Applications |

|---|---|---|

| ABS | Durable, impact‑resistant, cost‑effective | Electronics casings, dashboard panels, consumer goods |

| PC | Transparent, high-impact, heat-resistant | Optical lenses, safety shields, medical device covers |

| PA66 (Nylon) | High strength, wear resistance, self-lubricating | Gears, bearings, industrial fasteners |

| POM (Acetal) | Low-friction, tight tolerances, dimensionally stable | Valves, slide mechanisms, clar connectors |

| PP | Chemical-resistant, food-safe, flexible | Medical containers, fluid piping, lab equipment |

| PBT | Electrically insulating, strong, dimensionally stable | Automotive connectors, switches, appliance parts |

| PPS | High-temperature stable, chemically resistant | Pump housings, electronics under-hood parts |

| PEI | Flame-retardant, rigid, heat-resistant | Aerospace panels, automotive engine components |

| PEEK | Medical-grade, very high temp, inert | Surgical tools, implants, aerospace hydraulic seals |

| PVDF | Excellent chemical and UV resistance | Solar systems, acid pumps, fluid transfer systems |

These engineering plastics suit industries such as automotive, aerospace, electronics, food processing, medical, and chemical processing. Below, we explore their specific properties and performance trade-offs.

Mechanical, Thermal, and Chemical Properties Comparison

Understanding a material’s mechanical integrity, thermal limits, and chemical compatibility is vital. Use it to avoid failures in service conditions like fatigue, warping, or corrosion.

| Plastic | Tensile Strength (MPa) | Max Service Temp (°C) | Chemical Resistance | UV/Weather Resistance |

|---|---|---|---|---|

| ABS | 40–50 | 85 | Moderate | Low |

| PC | 60–70 | 125 | Good | Moderate |

| PA66 | 70–80 | 120 | Good | Low–Moderate |

| POM | 65–75 | 100 | Excellent | Moderate |

| PP | 30–40 | 100 | Excellent | Moderate |

| PBT | 50–60 | 130 | Good | Moderate |

| PPS | 90–100 | 220 | Excellent | High |

| PEI | 90–100 | 180 | Good | Excellent |

| PEEK | 100–120 | 250 | Excellent | Excellent |

| PVDF | 40–60 | 150 | Excellent | Excellent |

Practical guidance:

- For wear and mechanical strength, PA66, POM, PPS, PEI, and PEEK are top performers.

- For heat and sun exposure, PPS, PEI, PEEK, and PVDF offer lasting performance.

- For chemical contact, POM, PP, PPS, PEEK, and PVDF work best.

🔗 More detail available in MatWeb’s comprehensive database: MatWeb Polymer Materials

How to Select the Right Plastic for Structural or Functional Use

When choosing a polymer, consider:

-

Mechanical Load

Use tensile/flexural strength data to evaluate structural suitability. High-load applications favor PEEK, PPS, or PEI. -

Thermal Requirements

For use above 120°C (like engine components), opt for PPS, PEI, or PEEK. -

Wear and Moving Parts

POM and PA66 are excellent for bearings, racks, and sliders. -

Chemical Exposure

PVDF and PP resist acids, alcohols, and solvents typical in fluid-handling systems. -

Surface Requirements

Aesthetic parts may require ABS or PC; flame retardant/smooth components better made from PEI or PPS. -

Compliance Needs

Food or medical parts require FDA-rated PP or PEEK. Electrical use may require UL listings.

Engage early with Prime’s materials engineering team. We analyze your functional requirements to propose the ideal resin and production method.

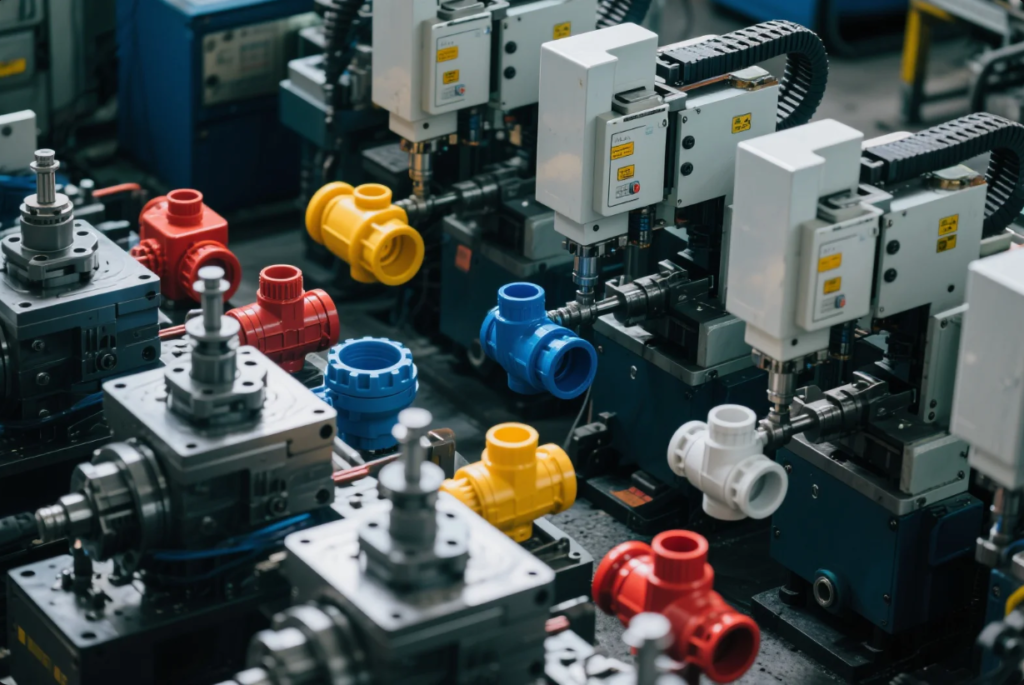

Case Study: Choosing the Right Engineering Plastic for CNC-Machined Valve Body

An industrial OEM needed a valve body with these functional demands:

- withstanding repeated cycles at 120°C

- resisting saline and cleaning agents

- long-term UV exposure

- CNC tolerance retention of ±0.02 mm

Testing Outcomes:

- POM – dimensionally stable & machinable, but chemically attacked by saline solutions.

- PPS – durable under heat and chemicals, but UV exposure caused slight surface degradation.

- PVDF – excelled in all areas, with stable dimensions, solvent resistance, and UV resilience.

Result: PVDF was chosen, and Prime produced precision CNC valve bodies with laser marking and moisture-barrier packaging.

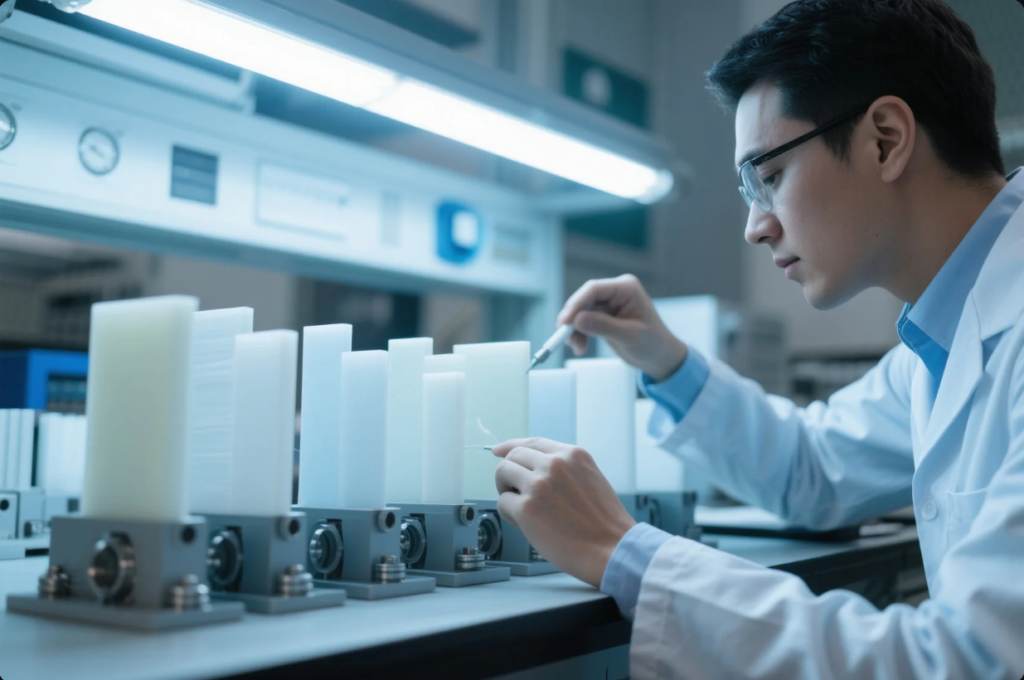

Conversion Guide – How Prime Supports Your Project

Prime’s end-to-end engineering plastic service ensures you hit quality and performance goals:

-

Expert Material Consultation

Select ideal resin based on load, temperature, wear, and fluid exposure. -

Prototyping in Chosen Plastics

Offer CNC, 3D prints, or small molded runs to verify functionality. -

DFM & Tooling Strategy

Flow analysis, draft optimization, and shrinkage compensation to ensure manufacturable design. -

Compliance & Certification Support

Provide FDA, UL, RoHS, CE documentation when required. -

Scale-Up Flexibility

From pilot runs to production volumes with ISO 9001 equipment and capabilities.

This process ensures a smooth transition from prototype to OEM production.

FAQs on Engineering Plastic Selection

Which plastic is best for chemical and UV exposure outdoor systems?

PVDF and PEI offer robust performance in challenging outdoor or chemical environments.

Do you supply FDA-approved parts for medical devices?

Yes. We produce parts using FDA-compliant PP, PEI, and PEEK materials, including cleanroom manufacturing.

Can PVDF be CNC machined to tight tolerances?

Yes—CNC machining of PVDF can maintain ±0.02 mm tolerance in small and medium part volumes.

Which plastic is most cost-effective for high-volume production?

PP, ABS, and nylon (PA66) typically offer the best cost-performance balance at scale.

Is PEEK worth using in aerospace or implant-level parts?

Absolutely. PEEK meets high-temp, chemical inertness, and certification demands for demanding industries.

Contact Prime for Expert Plastic Selection

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

Partner with Prime to access:

- Resin recommendations based on application and compliance

- Prototyping in multiple engineering plastics

- Production-ready parts manufactured to OEM specifications

- Comprehensive documentation and global logistics

Conclusion

Selecting the best engineering plastic empowers product success: structural integrity, environmental endurance, and regulatory compliance. Whether choosing ABS for economy or PEEK/PVDF for toughness, ensure your resin matches your product needs.

Reach out to Prime today for material guidance, rapid prototyping, and reliable production of industrial-grade parts.