Top 10 Metal Parts Manufacturers in 2025: Who Offers the Best Capabilities and Global Reach?

Finding reliable metal parts manufacturers in 2025 can be challenging. Issues like inconsistent quality, delayed deliveries, and poor communication are common.

This comprehensive guide explores the top 10 global metal parts manufacturers in 2025, detailing their capabilities, certifications, and key factors to consider when selecting a supplier.

Many suppliers promise quality. But only a few deliver. This guide compares the top 10 global metal parts manufacturers, including their strengths and global networks.

What Defines a Top-Tier Metal Parts Manufacturer in 2025?

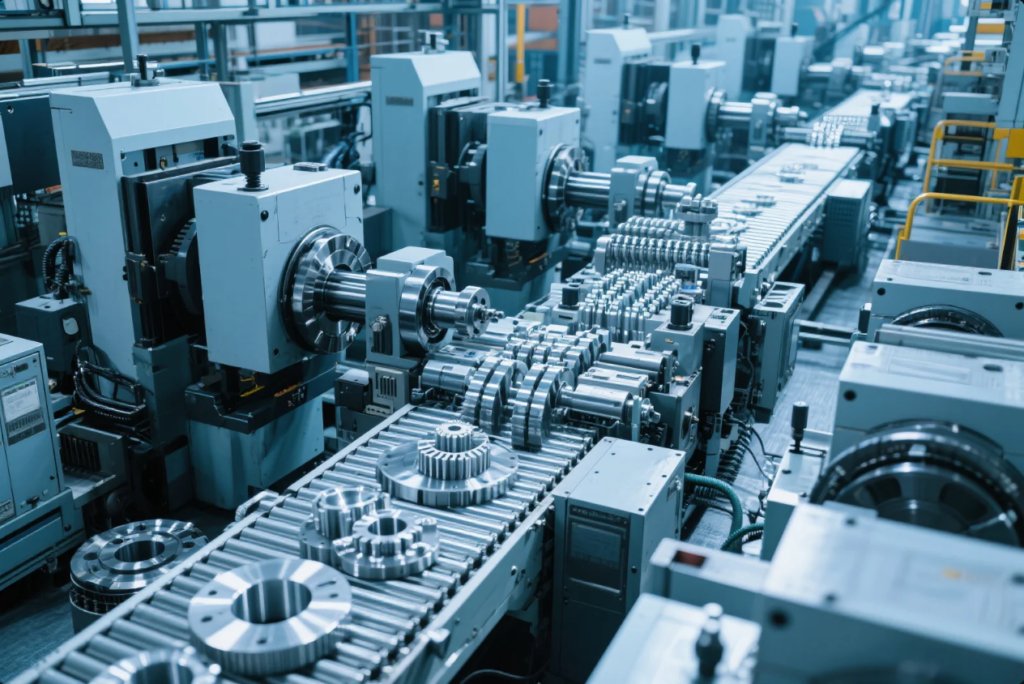

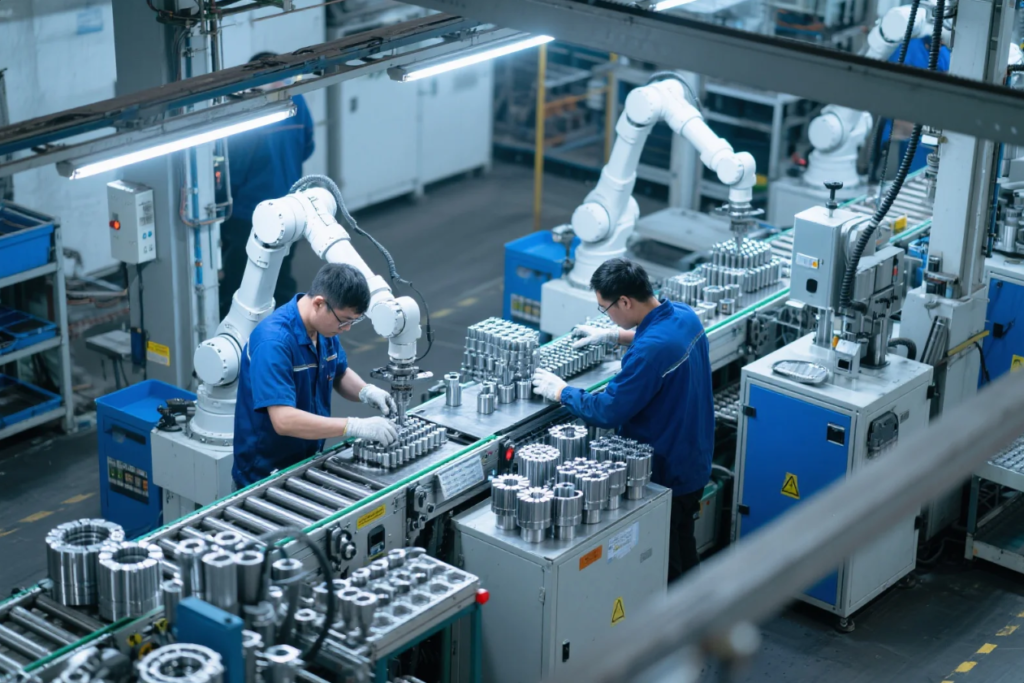

In 2025, leading metal parts manufacturers stand out through advanced capabilities, consistent quality, and certified processes. They offer full-spectrum services like stamping, CNC machining, welding, and casting.

Key Attributes of Leading Manufacturers:

- Certifications: ISO 9001, IATF 16949, AS9100 for quality assurance.

- Technology: CNC and automation improve speed and accuracy.

- Customization: OEM and ODM support for unique needs.

- Global Reach: Worldwide delivery and multilingual support.

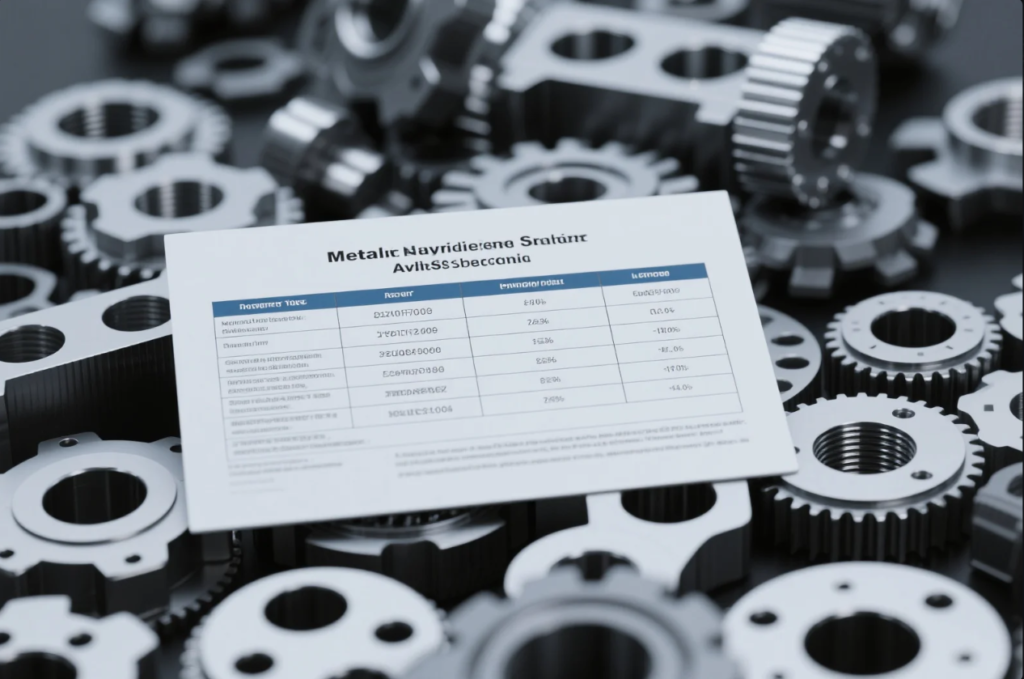

Top 10 Metal Parts Manufacturers in 2025

These companies are globally recognized for their production scale, technical capacity, and supply reliability.

| Rank | Company Name | Country | Key Products | Certifications |

|---|---|---|---|---|

| 1 | Shandong Prime International Trade | China | Stamping, CNC, Casting, Plastic | ISO 9001, Custom Capable |

| 2 | Würth Group | Germany | Fasteners, CNC | ISO, DIN, CE |

| 3 | Stanley Engineered Fastening | USA | Fasteners, Assembly Solutions | ISO, RoHS |

| 4 | Bossard Group | Switzerland | Precision Fasteners, Smart Tech | ISO, Lean Production |

| 5 | Fontana Gruppo | Italy | Automotive Fasteners | IATF 16949, ISO |

| 6 | Nippon Screw Co., Ltd. | Japan | Screws, Custom Machining | ISO, RoHS |

| 7 | Sundram Fasteners | India | Forged & Machined Components | ISO, TS 16949 |

| 8 | LISI Group | France | Aerospace Fasteners | ISO, AS9100 |

| 9 | Agrati Group | Italy | Cold Forging, Fasteners | ISO, IATF 16949 |

| 10 | PennEngineering | USA | PEM Fasteners, Precision CNC | ISO, RoHS |

Importance of Certifications in Ensuring Quality and Compliance

Certifications play a crucial role in verifying a manufacturer’s commitment to quality and compliance.

Common Certifications:

- ISO 9001: Quality management systems.

- IATF 16949: Automotive quality management.

- AS9100: Aerospace quality management.

- RoHS: Restriction of hazardous substances.

These certifications ensure that manufacturers adhere to international standards, providing confidence in product quality and reliability.

Key Considerations When Choosing a Metal Parts Supplier

Selecting the right supplier involves evaluating several critical factors:

- Production Capabilities: Assess the range of services offered, such as stamping, CNC machining, and casting.

- Quality Assurance: Verify certifications and quality control processes.

- Customization Options: Determine the flexibility in meeting specific design and packaging requirements.

- Delivery Performance: Review lead times and on-time delivery records.

- Communication Efficiency: Ensure clear and responsive communication channels.

By carefully considering these aspects, buyers can establish reliable partnerships that support their business objectives.

Frequently Asked Questions (FAQs)

Q1: What types of metal components do manufacturers typically produce?

A: Manufacturers often produce brackets, fasteners, casings, and custom parts in materials like steel, aluminum, or brass.

Q2: How do I choose the right metal component manufacturer?

A: Look for experience, certifications, and the ability to handle custom orders with consistent communication.

Q3: What is the typical lead time for metal component production?

A: Most suppliers offer lead times ranging from 2 to 6 weeks depending on complexity and order size.

Q4: What quality control measures do metal component manufacturers implement?

A: Reliable suppliers perform multiple inspections, provide documentation, and meet international certification standards.

Conclusion

Choose ISO-certified manufacturers with global reach to secure quality, price, and delivery.

Contact Shandong Prime International Trade today for a free consultation, tailored quotation, and fast custom sample.

We deliver high-quality CNC parts, custom stamping parts, and ISO-certified casting components across North America, Europe, and beyond. Expect rapid responses, expert support, and reliable logistics.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com/