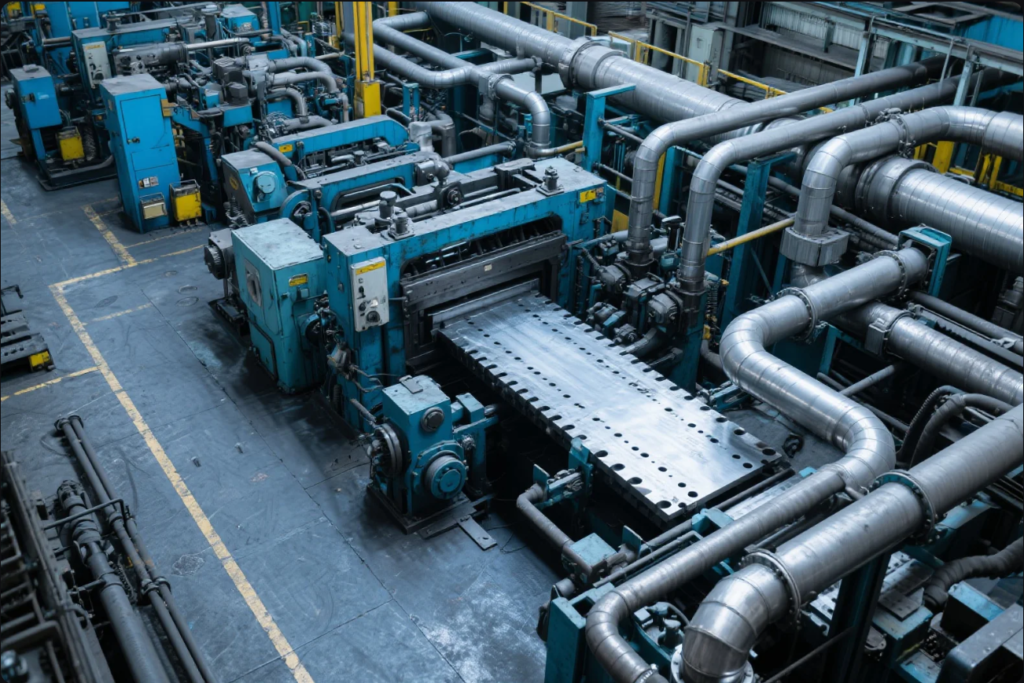

Top 10 Metal Stamping Parts Manufacturers in 2025 for Industrial Applications?

I struggle to find reliable stamping parts. I worry about quality, lead time, and price. This article lists top manufacturers and advises how to choose them.

This guide ranks the top 10 metal stamping manufacturers in 2025. It covers quality standards, lead time, MOQ, certifications, and precision. It helps engineers and procurement managers make informed sourcing decisions.

What Makes a Reliable Supplier of Custom Stamped Metal Components?

I faced parts quality issues and delivery delays. That disrupted assembly lines. Reliable suppliers must meet these essential criteria:

- Quality control: CMM inspection, gauge checks, and detailed batch reports.

- Customization ability: Support design tweaks, small runs, and multiple materials.

- Clear communication: Weekly updates and a dedicated project contact.

Dive‑Deeper Analysis

Quality Control

Suppliers need standardized inspection systems, use CMM devices and gauges, and deliver detailed QC reports.

Customization Ability

They should accept custom CAD files, prototypes, and low-volume orders (100–500 pcs). Quick tooling adjustments are a plus.

Communication

They must offer weekly production updates and have a dedicated manager assigned to your project.

| Factor | Why It Matters | Good Practice |

|---|---|---|

| Quality control | Ensures parts meet specifications | CMM, gauge checks, detailed reports |

| Customization | Enables design flexibility | CAD review, retooling, sample approvals |

| Communication | Keeps schedule on track | Weekly updates, single contact per order |

These practices help prevent delays and cost overruns before they occur.

Certifications and Quality Standards Required in Metal Stamping

Many suppliers claim to be "ISO-certified". I need verified proof. Genuine certifications matter:

- ISO 9001 – for overall quality control

- IATF 16949 – required for automotive-grade parts

- RoHS / REACH – ensuring electronics safety for EU and US

- CE / UKCA / SASO – region-specific export certifications

Dive‑Deeper Analysis

ISO 9001

Provides a framework for consistent manufacturing processes and quality control.

IATF 16949

Adds automotive traceability and defect prevention to ISO 9001 practices.

RoHS / REACH

Limits hazardous materials for electronics parts in global compliance.

Regional Standards

- CE / UKCA for Europe/UK markets

- SASO for GCC region exports

| Certification | Industry / Region | Key Benefit |

|---|---|---|

| ISO 9001 | All industries | Quality consistency |

| IATF 16949 | Automotive | Part traceability and defect control |

| RoHS / REACH | Electronics / EU | Legal compliance for hazardous materials |

| CE / UKCA | Europe / UK | Market access |

| SASO | Middle East | Export certification to GCC countries |

I always verify certificates through portals like TÜV Rheinland and SGS.

Comparing Lead Times and MOQ Among Global Stamping Providers

Lead time and MOQ directly affect product timelines and cost.

-

Lead Time

- Standard tooling: 4–8 weeks

- Express tooling: 2–4 weeks (higher tooling cost)

-

MOQ

- China: 500–2,000 pcs

- Europe: 1,000–5,000 pcs

- North America: 2,000+ pcs

Dive‑Deeper Analysis

Lead Time Factors

Speed depends on tooling complexity, tooling in-house v.s. external, and factory backlog. Express tooling cuts lead time in half, but adds 15–40% to costs.

MOQ Trade‑offs

Lower MOQ aids prototyping but raises per-unit cost. Higher MOQ reduces unit price but locks up inventory. A balanced supplier offers both.

Regional Comparison

| Region | Lead Time | MOQ Range | Unit Cost |

|---|---|---|---|

| China | 2–6 weeks | 500–2,000 pcs | Lowest unit price |

| Europe | 4–8 weeks | 1,000–5,000 pcs | Moderate unit price |

| North America | 3–7 weeks | 2,000+ pcs | Higher unit price |

Chinese suppliers often win on cost and MOQ. North American suppliers excel at compliance and logistics.

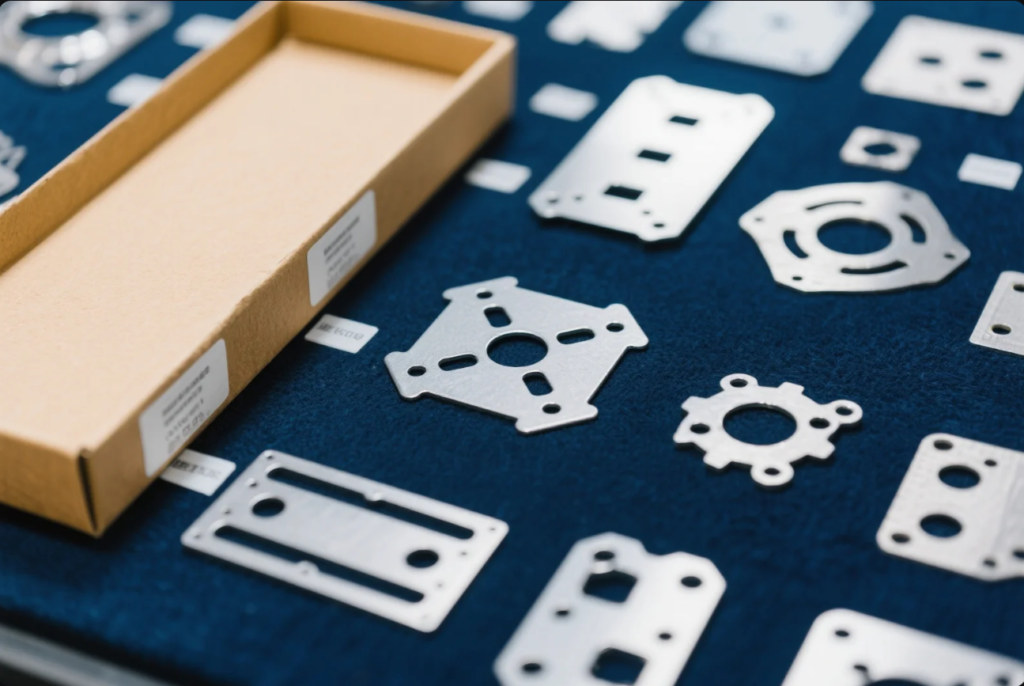

How PrimeCustomParts.com Ensures Consistent Stamping Precision

PrimeCustomParts.com delivers ±0.02 mm tolerance consistently. Their approach includes:

- In‑house tooling and machining

- ISO 9001 quality system

- Daily pilot-CMM inspections

- Full batch traceability and QC records

Dive‑Deeper Explanation

1. Tooling & Pilot Runs

Prime reviews your CAD for manufacturability, builds a die, and runs 100–200 pcs pilot batch. They record sample measurements daily.

2. Precision Inspection

They use CMM and micrometers, detect deviations immediately, and initiate corrections.

3. ISO 9001 Workflow

All processes are logged with operator, timestamp, and data for traceability.

4. Traceability

| Stage | Tool or Process | Benefit |

|---|---|---|

| Pilot production | CMM & micrometers | Early error detection |

| Full production | Statistical QC | Maintain ±0.02 mm tolerance |

| Batch documentation | Labels, QC sheets | Enables tracing and recalls |

| Process feedback | On-site audits | Tracks tool wear and drift |

This system ensures precision for electronics, automotive, and medical parts. For more insights, see The Fabricator.

Top 10 Metal Stamping Manufacturers in 2025 (Ranked)

Here are the top global providers, ranked by quality, speed, MOQ, certifications, and precision:

| Rank | Manufacturer | Country | Certifications | MOQ | Lead Time | Strengths |

|---|---|---|---|---|---|---|

| 1 | PrimeCustomParts.com | China | ISO 9001, RoHS | 500 pcs | 2–6 weeks | In‑house tooling, ±0.02 mm precision, fast delivery |

| 2 | ABC Vietnam | Vietnam | ISO 9001, RoHS | 500 pcs | 3–5 weeks | Progressive dies, reliable shipping |

| 3 | StampTech USA | USA | ISO 9001, RoHS | 2,000 pcs | 3–6 weeks | Local support, tooling services |

| 4 | EuroStamp Srl | Italy | ISO 9001, CE | 1,200 pcs | 5–8 weeks | Precision stamping, ideal for prototyping |

| 5 | QRS Metal Works | India | ISO 9001, RoHS | 800 pcs | 3–5 weeks | Competitive price, flexible MOQ |

| 6 | MetalStamp Co., Ltd. | China | ISO 9001 | 600 pcs | 3–7 weeks | Standard stamping at lower cost |

| 7 | PrecisionStamp BV | Netherlands | ISO 9001, RoHS | 1,500 pcs | 4–6 weeks | Electronic-grade precision, plating capability |

| 8 | K‑Stamper Korea | South Korea | ISO 9001, REACH | 1,000 pcs | 4–6 weeks | High-tech systems, plating options |

| 9 | LatAmStamping | Mexico | ISO 9001 | 2,000 pcs | 4–8 weeks | Near‑shoring for US buyers, bilingual staff support |

| 10 | AusStamp Pty Ltd | Australia | ISO 9001, CE | 1,500 pcs | 5–8 weeks | Regional compliance, small batch production |

These ten companies represent top-tier stamping capabilities for 2025.

FAQs

-

What is the difference between stamping and CNC parts?

Stamping uses dies to form shapes quickly in volume. CNC cuts parts one at a time. Stamping suits large, simple parts; CNC suits small runs and complex geometries. -

What certifications should I require for electronics parts?

Ensure suppliers hold RoHS, REACH, and ISO 9001. This guarantees regulatory compliance and full traceability. -

Can I order low volumes like 100–200 pcs?

Yes—many suppliers accept low MOQ. While unit cost is higher, it’s ideal for prototyping and market testing. -

How do express tooling options work?

Express tooling expedites die manufacturing using rapid machining or multi-shift operations. Lead time is halved, cost rises \~15–40%. -

How reliable are QC reports from stamping suppliers?

Leading suppliers provide detailed PDF QC reports with measurement data, photos, operator initials, and sign-offs. -

How do I verify supplier certifications?

You can request scanned certificates or serial numbers and verify via SGS, TÜV Rheinland, or other accredited portals. -

Is packaging included in price?

Standard packaging is included. Special packaging like foam inserts, vacuum packs, or export crating is extra—specify early in quotes.

Conclusion & Contact Information

PrimeCustomParts.com is your trusted partner for ISO‑certified, precision stamping parts delivered with fast turnaround and cost advantage. With in‑house tooling and full QC traceability, they ensure ±0.02 mm tolerance. Their 20‑year experience spans stamping, CNC, casting, fasteners, and plastics—covering your all-in-one parts needs.

Visit PrimeCustomParts.com or email [email protected] to get your free consultation, quick quote, and custom solution today. We ensure reliable quality and speedy delivery for your next project.