Top 10 Sheet Metal Parts Manufacturers in 2025: Capabilities, Expertise, and Selection Criteria?

Navigating the evolving landscape of sheet metal fabrication in 2025? Discover the top manufacturers leading the industry with unparalleled capabilities and expertise.

This comprehensive guide delves into the top 10 sheet metal parts manufacturers of 2025, highlighting their unique strengths, technological advancements, and key selection criteria to aid in your sourcing decisions.

Stay ahead in your procurement strategy by understanding what sets these industry leaders apart.

Industry Outlook for Sheet Metal Manufacturing in 2025

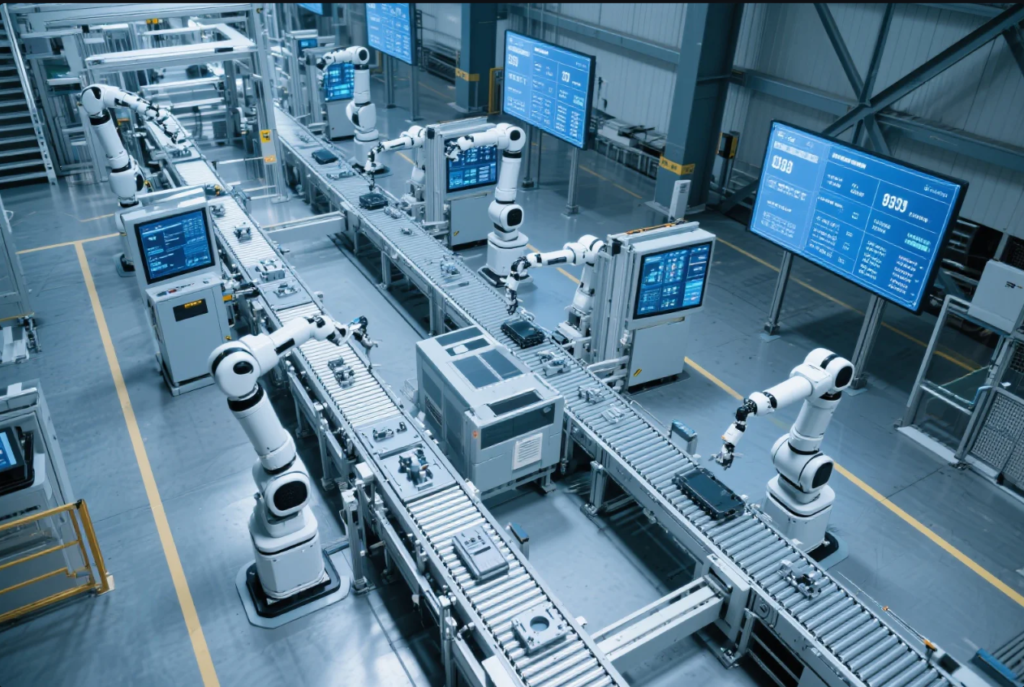

The sheet metal industry in 2025 is experiencing significant growth, driven by advancements in automation, sustainable practices, and increasing demand across various sectors.

Key Trends:

- Automation and AI Integration: Enhanced precision and efficiency in fabrication processes.

- Sustainable Practices: Adoption of eco-friendly materials and energy-efficient machinery.

- Diversification: Expansion into sectors like renewable energy and electric vehicles.

These trends are reshaping the industry, making it imperative for manufacturers to adapt and innovate.

Top 10 Sheet Metal Parts Manufacturers in 2025

1. Steel Dynamics

Overview:

Steel Dynamics stands out with its vertically integrated operations, ensuring quality control from raw materials to finished products.

Capabilities:

- Advanced automation in production lines.

- Wide range of sheet metal products catering to automotive and construction sectors.

Certifications: ISO 9001, ISO 14001

Website: www.steeldynamics.com

2. Nucor Corporation

Overview:

Nucor is renowned for its commitment to sustainability and innovation in steel production.

Capabilities:

- Extensive product range including custom sheet metal parts.

- Emphasis on recycling and reducing carbon footprint.

Certifications: ISO 9001, LEED

Website: www.nucor.com

3. Prime Custom Parts

Overview:

Established in 1993, Prime Custom Parts offers comprehensive solutions in sheet metal fabrication with a focus on quality and customization.

Capabilities:

- Specializes in stamping, CNC machining, and welding.

- Offers rapid prototyping and mass production services.

Certifications: ISO 9001

Website: www.primecustomparts.com

Contact: [email protected]

4. Arconic Corporation

Overview:

Arconic delivers high-performance sheet metal parts, especially for aerospace and automotive industries.

Capabilities:

- Expertise in lightweight aluminum sheet metal fabrication.

- Utilizes cutting-edge technology for precision manufacturing.

Certifications: AS9100, ISO 9001

Website: www.arconic.com

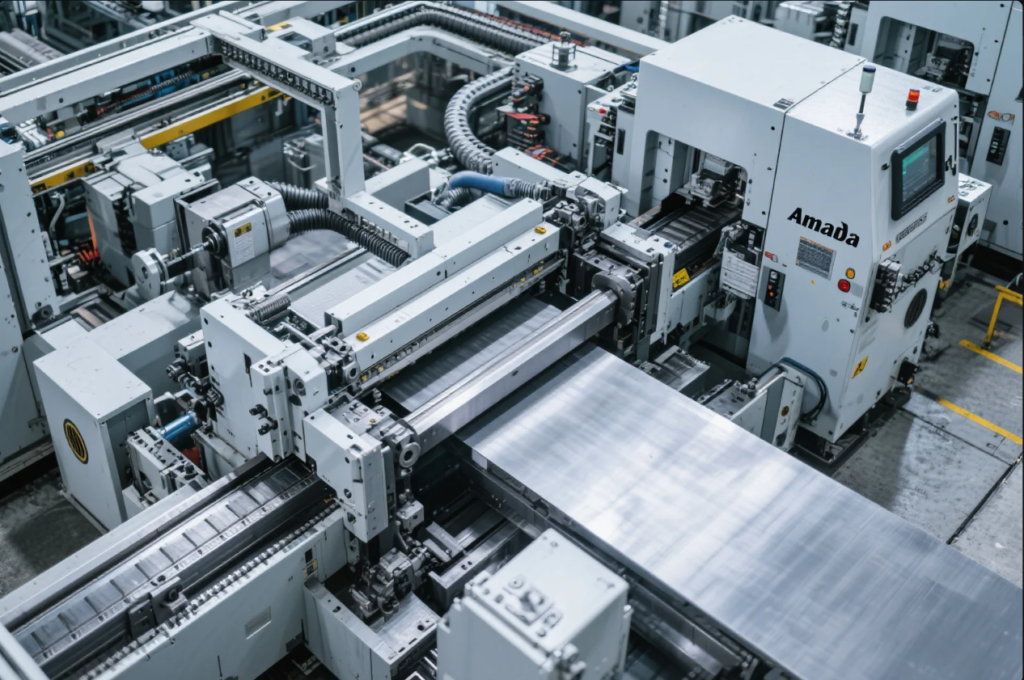

5. AMADA Co., Ltd.

Overview:

AMADA is a global leader in sheet metal machinery and fabrication solutions.

Capabilities:

- Offers a wide array of fabrication equipment and services.

- Provides training and support for efficient operations.

Certifications: ISO 9001, ISO 14001

Website: www.amada.com

6. Trumpf Group

Overview:

Trumpf specializes in high-technology sheet metal processing machines and smart factory solutions.

Capabilities:

- Integration of laser technology in sheet metal fabrication.

- Focus on digitalization and Industry 4.0.

Certifications: ISO 9001, ISO 14001

Website: www.trumpf.com

7. Tower International

Overview:

Tower International provides structural metal components for the automotive industry.

Capabilities:

- Specializes in body-structure stampings and assemblies.

- Operates multiple facilities across North America and Europe.

Certifications: IATF 16949, ISO 9001

Website: www.towerinternational.com

8. Ulbrich Stainless Steels & Special Metals

Overview:

Ulbrich offers a diverse range of stainless steel and special metal products with precision engineering.

Capabilities:

- Produces custom rolled strip and foil products.

- Serves industries like aerospace, medical, and electronics.

Certifications: ISO 9001, AS9100

Website: www.ulbrich.com

9. Vallourec

Overview:

Vallourec is a multinational company specializing in hot rolled seamless steel tubes and sheet metal components.

Capabilities:

- Provides solutions for energy, construction, and automotive sectors.

- Emphasizes innovation and sustainability.

Certifications: ISO 9001, ISO 14001

Website: www.vallourec.com

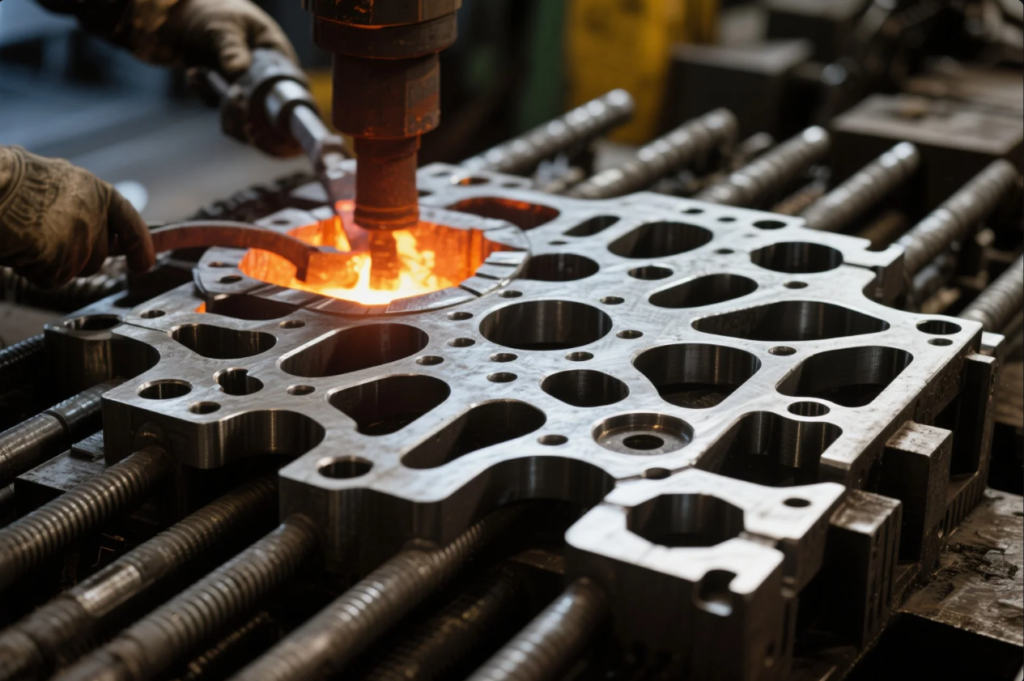

10. Wyman-Gordon

Overview:

Wyman-Gordon, a subsidiary of Precision Castparts Corp., manufactures complex metal components for aerospace and industrial markets.

Capabilities:

- Expertise in forging and precision machining.

- Supplies critical components for high-stress applications.

Certifications: AS9100, ISO 9001

Website: www.wyman-gordon.com

Key Selection Criteria for Choosing a Manufacturer

When selecting a sheet metal parts manufacturer, consider the following criteria:

-

Technical Expertise:

- Evaluate the manufacturer’s experience in your specific industry.

- Assess their ability to handle complex designs and materials.

-

Quality Assurance:

- Ensure they hold relevant certifications (e.g., ISO 9001, AS9100).

- Review their quality control processes and track record.

-

Production Capabilities:

- Confirm their capacity to meet your volume requirements.

- Check for advanced machinery and technology integration.

-

Lead Times and Flexibility:

- Inquire about standard lead times and their ability to handle urgent orders.

- Assess their adaptability to design changes.

-

Cost Competitiveness:

- Request detailed quotations and compare pricing structures.

- Consider the total cost of ownership, including logistics and post-production support.

-

Customer Support:

- Evaluate their communication responsiveness and technical support.

- Look for value-added services like design assistance and prototyping.

FAQs

Q1: What industries benefit most from sheet metal fabrication?

A: Industries such as automotive, aerospace, construction, electronics, and medical devices heavily rely on sheet metal fabrication for components and structures.

Q2: How does automation impact sheet metal manufacturing?

A: Automation enhances precision, reduces production time, and minimizes human error, leading to higher efficiency and consistent quality.

Q3: Why are certifications like ISO 9001 important?

A: Certifications ensure that manufacturers adhere to international quality standards, providing assurance of product reliability and process consistency.

Q4: Can manufacturers handle both prototyping and mass production?

A: Many top manufacturers offer services ranging from rapid prototyping to large-scale production, catering to various project stages.

Q5: How do I request a quote from Prime Custom Parts?

A: Visit www.primecustomparts.com or contact them directly at [email protected] for inquiries and quotations.

Conclusion

Selecting the right sheet metal parts manufacturer in 2025 requires careful consideration of capabilities, certifications, and industry expertise. The manufacturers listed above exemplify excellence in the field, offering reliable solutions for diverse industrial needs.

For tailored solutions and expert guidance, reach out to Prime Custom Parts at www.primecustomparts.com or email [email protected] to discuss your project requirements.