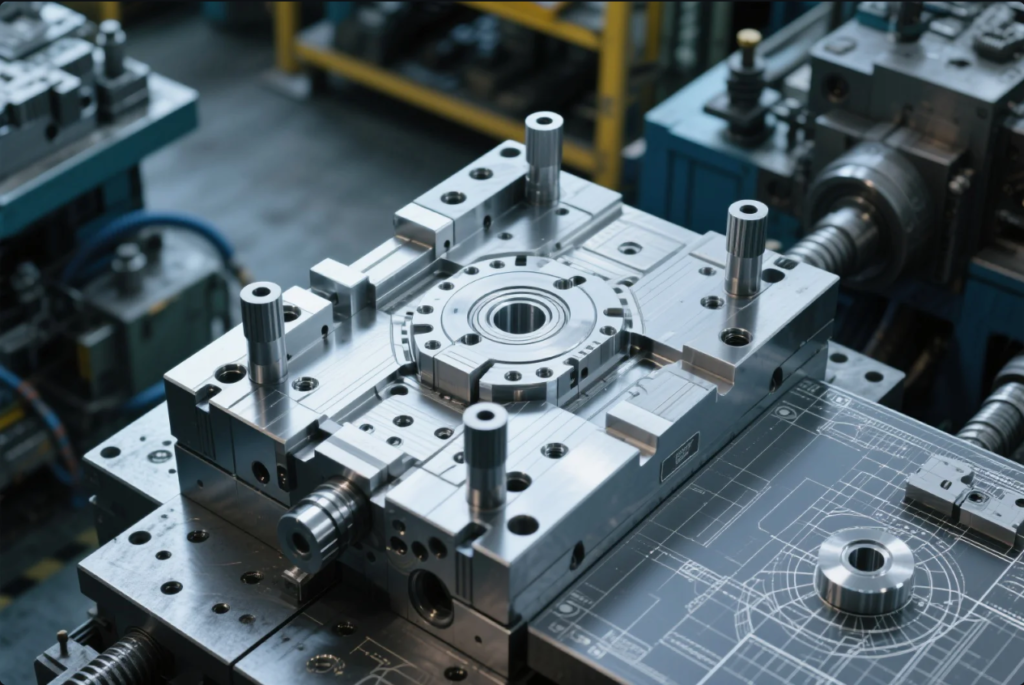

Top 10 Tips for Designing Durable Molds for Custom Metal Parts: How to Boost Lifespan & Performance?

Injection molds face extreme wear, high-pressure cycles, and tight tolerances. A poorly designed mold leads to costly downtime and rejected parts.

This guide shares 10 proven tips for designing long-lasting molds for custom metal parts. Learn how material selection, thermal management, draft angles, and parting line placement all impact durability.

These tips help product engineers, buyers, and tooling managers avoid common mistakes and get better results from every mold investment.

What is the best steel for molds?

Not all steels are created equal. The wrong choice increases cracking, corrosion, and maintenance frequency.

The best steel for molds depends on application, volume, and required surface finish. Common options include P20, H13, S136, and 420 stainless.

Comparing Mold Steels

| Steel Grade | Hardness (HRC) | Key Benefit | Best For |

|---|---|---|---|

| P20 | 28–32 | Cost-effective & easy to machine | Low to medium production volumes |

| H13 | 44–52 | Excellent thermal fatigue resistance | High-temp applications |

| S136 | 48–52 | Corrosion resistant | High polish, wet environments |

| 420 SS | 48–55 | Mirror finish capability | Cosmetic parts and medical tools |

At Prime, we match mold steel to the client’s production plan. Our ISO-certified mold engineers help choose the right steel to balance tooling cost and life cycle performance.

For a professional guide, see ASSAB’s steel comparison charts.

What material is most commonly used for molding?

Mold durability depends not only on steel—but also on what goes into it.

Thermoplastics like ABS, polypropylene (PP), and polycarbonate (PC) are the most commonly used materials for injection molding. For metal injection molding (MIM), stainless steel powders are widely used.

Material Impact on Mold Wear

Different resins and powders cause different levels of mold stress. Abrasive fillers (e.g., glass fibers) wear down tools faster. Corrosive additives (e.g., halogenated flame retardants) require corrosion-resistant steel.

| Material | Mold Impact | Common Use |

|---|---|---|

| ABS | Low abrasion | Enclosures, automotive |

| PP | Low friction | Packaging, lab containers |

| PC | High temp | Transparent or impact parts |

| SS316L (MIM) | High density | Precision metal components |

Want more on plastic material specs? Visit MatWeb’s polymer data sheets.

At Prime, we review your part material and match it with suitable tooling. We also offer trial runs using customer-specified or in-stock resins and metal powders.

What considerations do part designers have to make when a part will be produced with injection molding?

Not every CAD model is mold-ready. Complex shapes, undercuts, and tight corners can increase cost or even make tooling impossible.

When designing parts for injection molding, engineers must consider draft angles, wall thickness, parting line location, and material flow. Early DFM review helps reduce tool revisions and cycle time.

Critical Design Factors for Durable Molds

| Factor | Why It Matters | Best Practice |

|---|---|---|

| Draft Angle | Eases part ejection | 1–3° standard; more for textured walls |

| Wall Thickness | Prevents warping and sink marks | Keep walls uniform (2–4 mm) |

| Undercuts | Affects mold complexity | Use side actions or redesign |

| Parting Line | Impacts flash and mold strength | Place along flat, accessible areas |

| Material Flow | Ensures complete filling | Simulate with mold flow software |

See Protolabs’ design tips for quick guides to injection mold-friendly parts.

At Prime, we provide free DFM reports for all custom mold orders, ensuring you avoid costly tooling mistakes before steel is cut.

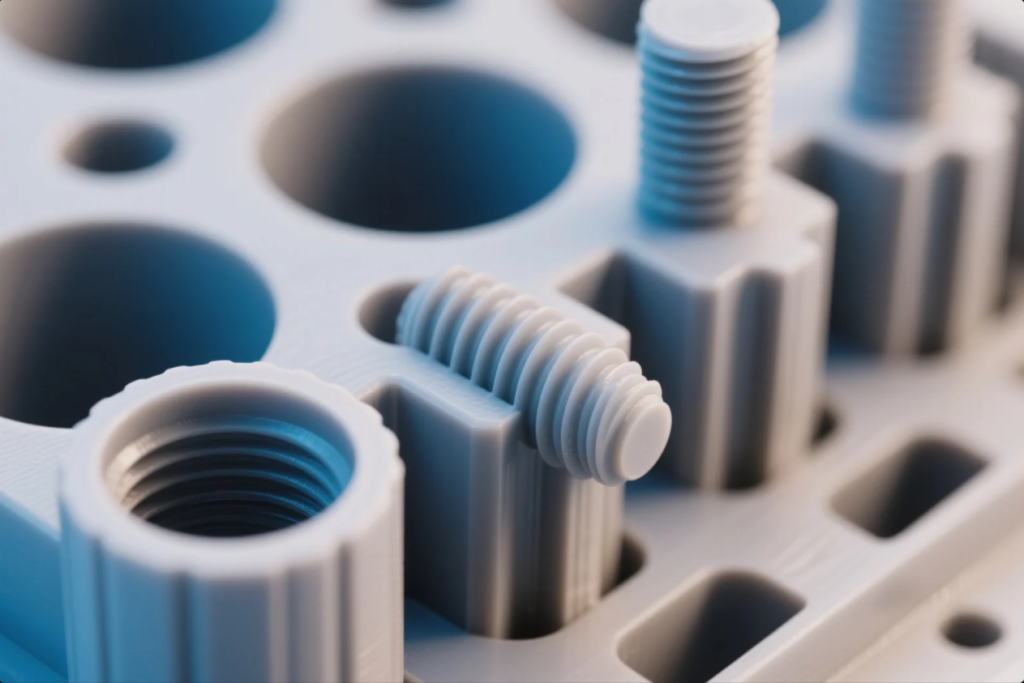

Can threads be injection molded?

Threaded parts usually require secondary machining—but not always.

Yes, external and internal threads can be molded. However, the design must support draft angles or require unscrewing cores to avoid damage during ejection.

How to Mold Threads Effectively

| Thread Type | Mold Feasibility | Tips |

|---|---|---|

| External Threads | Easy to mold | Add draft or use split molds |

| Internal Threads | More complex | Use collapsible or unscrewing cores |

| Metal Threads | Not molded—inserted | Use metal inserts before molding |

Read Protolabs’ guide to molded threads for in-depth design guidance.

Prime engineers offer insert-molding options and in-house unscrewing core systems. That means fully molded threaded parts—without extra machining time or cost.

FAQs

Q1: How long should a good mold last?

A1: Depending on material and design, a steel mold can last from 100,000 to over 1 million cycles.

Q2: Can you mold stainless steel parts?

A2: Yes, via metal injection molding (MIM). We mold 316L, 17-4PH, and custom alloys.

Q3: What are typical mold tolerances?

A3: Prime molds offer ±0.01 mm precision in CNC milled components and ±0.03 mm in molded plastics.

Q4: How long does it take to build a mold?

A4: Standard lead time is 20–30 days, including DFM and sampling.

Q5: Do you provide mold maintenance support?

A5: Yes, we include tooling service guidelines and offer refurbishing for high-volume clients.

Contact Information

Looking to build a long-life mold for your next custom part?

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

We offer:

- Free mold design reviews

- Rapid prototyping and DFM feedback

- Full mold production and export tooling

- ISO9001 quality control and traceability

Choose Prime to design molds that last—and deliver.

With 10 production lines, on-time delivery, and global engineering support, Prime is your trusted partner for precision tooling and custom component manufacturing.