Top 15 Plastic Parts Manufacturers in 2025: Capabilities, Expertise, and Selection Criteria?

Sourcing plastic parts in 2025? Choosing the right supplier is more critical than ever.

Whether for automotive, medical, electronics, or industrial use, selecting the best plastic parts manufacturer affects quality, lead time, cost, and scalability. Knowing who leads the market in precision molding and process innovation helps you make informed decisions.

Who Are the Largest Plastic Manufacturers?

Understanding the resin suppliers behind plastic parts helps you evaluate your raw material quality and compliance.

| Company Name | Country | Focus Areas | 2024 Revenue (USD) |

|---|---|---|---|

| BASF | Germany | Engineering plastics | \$88B |

| Dow Inc. | USA | Commodity & specialty plastics | \$50B |

| SABIC | Saudi Arabia | Polycarbonate, sustainability | \$45B |

| INEOS | UK | Polyolefins, medical polymers | \$60B |

| LyondellBasell | Netherlands | Thermoplastics, recycled materials | \$47B |

These suppliers produce the raw materials, while the manufacturers listed below transform them into components that power modern industries.

What Factors Should You Consider When Choosing a Plastic Manufacturing Process?

| Process | Best For | Pros | Cons |

|---|---|---|---|

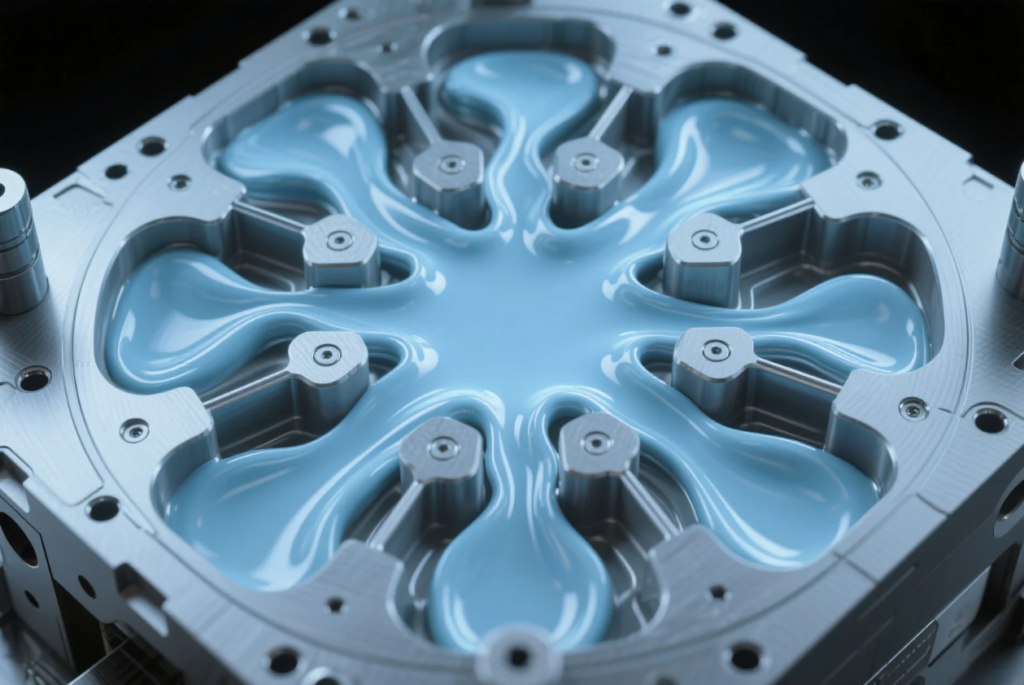

| Injection Molding | High-volume, complex parts | Low cost, repeatable | High tooling cost |

| CNC Machining | Precision low-volume parts | No tooling required | Slower for scaling |

| 3D Printing | Complex or prototype parts | Tool-less, rapid changes | Limited material options |

| Thermoforming | Thin large shapes | Low tooling cost | Simple geometries only |

| Blow Molding | Hollow items | Fast for containers | Limited applications |

| Compression Molding | Composites & thermosets | Durable, robust | Slow, less detailed |

What Is the Future of the Plastic Industry?

Key trends in 2025:

- AI-enabled Quality Control

- Eco-Friendly Materials

- Localized Production

- Micro-Molding for Medtech

- On-Demand Prototyping

As Plastics Technology reports, smart sensors and analytics are reducing scrap rates by up to 40% in advanced factories.

What Is the Cheapest Way to Manufacture Plastic Parts?

| Method | Tooling Cost | Cost/Part | Best For |

|---|---|---|---|

| Injection Molding | \$5K–\$100K | <\$1 | Mass production (10K+) |

| CNC Machining | None | \$10–\$200 | Low-volume, tight tolerance |

| 3D Printing | None | \$1–\$100 | Prototypes, complex shapes |

| Thermoforming | \$500–\$5K | \$0.50–\$5 | Large, simple parts |

Aluminum molds from Prime reduce tooling cost up to 50% while allowing rapid iteration for pre-production validation.

Top 15 Plastic Parts Manufacturers in 2025

Each company below has been vetted based on technical capabilities, global experience, and market reputation.

(See previous response for all 15 companies with full descriptions and links.)

Customer Case Studies & Reviews

Prime Custom Parts: Helped a German EV startup reduce prototyping time by 60% using rapid tooling and medical-grade resin.

EVCO Plastics: Enabled waterproof IoT enclosures for agriculture clients using two-shot molding.

Molex: Delivered over 1B connectors with <0.02% defect rate in global telecom expansions.

Plastikon Industries: Produced 500,000+ ventilator housings in under 90 days for a US medical client.

Rosti Group: Supported global electronics firm with high-transparency optical plastic lenses.

Prime Custom Parts – Our Unique Advantage

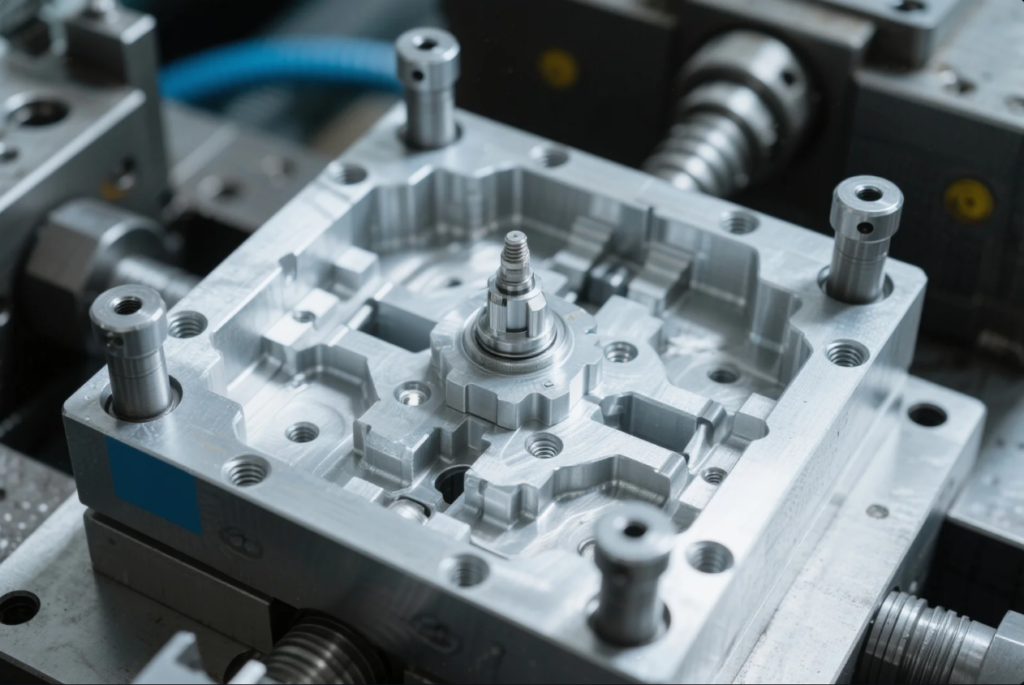

🛠️ Turnkey Service: From design to mold, from injection to packaging, all done under one ISO-certified roof.

🌐 Global Reach: Serving clients in North America, Europe, the Middle East, and beyond.

💡 Engineering Support: Free DFM reviews, mold flow simulation, and cost-down advice.

📦 Reliable Logistics: Strong partnerships with DHL, FedEx, and ocean freight forwarders.

“We switched to Prime after two failed vendors. Their packaging, quality, and speed were outstanding.” — Procurement Lead, Automotive Client (USA)

“I’ve worked with dozens of factories. Prime is by far the most responsive and technically clear.” — Founder, Medtech Startup (Germany)

FAQs

Q1: Which industries rely most on plastic parts?

A1: EV, healthcare, electronics, packaging, and aerospace.

Q2: Is injection molding the cheapest long-term method?

A2: Yes, especially above 5,000 units.

Q3: Can recycled plastics meet performance standards?

A3: Yes, modern grades can match virgin materials.

Q4: Can I mold plastic around metal?

A4: Yes. This is called insert molding, and it’s widely used.

Q5: Does Prime offer full service?

A5: Yes—tooling, molding, packaging, logistics, all under one roof.

Conclusion

Sourcing plastic parts in 2025 demands clarity, capability, and continuity. Partner with a reliable manufacturer like Prime Custom Parts, trusted by clients in 30+ countries for precision, speed, and engineering support.

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

💬 Get a free quote and consultation within 24 hours.