Top 5 Cost-Saving Tips for Custom Metal Part Mold Development: How to Cut Costs Without Cutting Corners?

Mold development often runs over budget due to design errors, wrong materials, or inefficient tooling strategies.

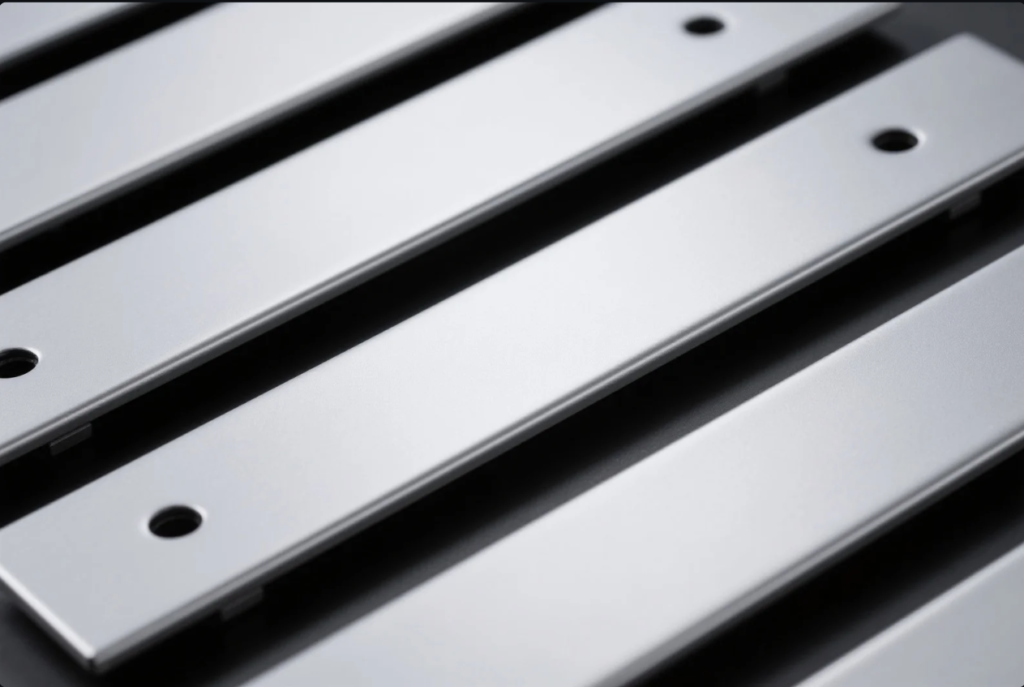

In this guide, we share 5 proven, practical tips to reduce mold development costs for custom metal parts. Whether you’re producing sheet metal casings, CNC-milled housings, or cast components, these tips will help you stay on budget.

Skip the shortcuts. Use smart design, expert planning, and the right partners to save money and still meet technical requirements.

How much does it cost to fabricate metal parts?

Costs vary, but tooling is always a major portion.

The cost to fabricate metal parts depends on part complexity, material, volume, and surface finish. Tooling for custom molds can range from \$2,000 to \$50,000+, while per-part costs depend on batch size and processing method.

Typical Fabrication Cost Ranges (2025)

| Process | Tooling Cost (USD) | Per-Part Cost (USD) | Notes |

|---|---|---|---|

| Sheet Metal Stamping | \$5,000–\$25,000 | \$0.30–\$5.00 | Higher initial investment |

| Die Casting | \$8,000–\$40,000 | \$0.50–\$10.00 | Efficient for high volumes |

| CNC Machining | No mold | \$5.00–\$100.00 | Best for low-volume parts |

| MIM (Metal Injection) | \$10,000–\$50,000 | \$0.80–\$7.00 | Requires tooling and sintering |

At Prime, we reduce upfront costs through shared tooling, modular mold inserts, and hybrid casting options.

For cost calculators, try Xometry’s online quote engine.

What is the greatest danger when working with sheet metal?

Cutting corners—literally—can lead to serious injuries.

The biggest danger when working with sheet metal is sharp edges. These can cause deep cuts or lacerations. Mishandling heavy sheets can also result in back injuries, crush hazards, or eye damage from flying sparks.

Sheet Metal Safety Tips

- Always wear gloves and safety glasses

- Deburr all cut edges before handling

- Use edge rollers and guards on exposed material

- Label sharp corners in tooling and nesting

- Keep a clear area around press brakes and punch machines

Prime engineers follow ISO 45001 safety protocols for sheet metal mold development and part handling.

See OSHA’s guide on metalworking safety.

What skill is indispensable for sheet metal workers when preparing metal surfaces for welding?

Before you weld, you must prep—and prep well.

The most important skill is surface preparation. A sheet metal worker must know how to grind, clean, and align surfaces to ensure a strong, clean weld. Poor prep leads to contamination, weak joints, or cosmetic defects.

Essential Prep Tasks

- Remove oxide layers or coatings (like galvanized zinc)

- Grind or brush edges to bare metal

- Align edges using jigs or tack welds

- Clean with solvent to remove oils or grease

At Prime, we apply precision surface prep protocols, including pre-weld grinding and laser cleaning, especially for stainless or coated sheets.

Check Weld.com’s welding prep guide.

How can we improve the appearance of a sheet metal product?

Sometimes, it’s not just about performance—it’s about how the part looks.

Improving the appearance of a sheet metal product involves proper surface finishing, joint design, and coating. Choosing the right grain, polish, or paint makes parts visually consistent and corrosion resistant.

Common Appearance Enhancements

| Method | Description | When to Use |

|---|---|---|

| Brushing/Polishing | Smooths surface; removes marks | Cosmetic panels, handles |

| Powder Coating | Durable color and corrosion layer | Outdoor or visible parts |

| Anodizing | Colored oxide layer (aluminum) | Lightweight enclosures |

| Welding Seam Hiding | TIG or MIG with cosmetic blending | Visible product faces |

At Prime, we support full post-processing options including anodizing, e-coating, bead blasting, and clear coat—delivered inspection-ready.

For finish inspiration, explore GrainFinishes.com’s visual gallery.

FAQs

Q1: What’s the fastest way to reduce mold cost?

A1: Use modular mold inserts, limit undercuts, and share cavities when possible.

Q2: Can aluminum molds be used for metal parts?

A2: Yes—for soft metal casting or prototype stamping. Limited shot life.

Q3: How do I avoid welding warpage on sheet metal?

A3: Use stitch welding, pre-clamp fixtures, and controlled heat input.

Q4: What surface finish is best for corrosion resistance?

A4: Powder coating or e-coating are both effective and affordable.

Q5: Does Prime offer DFM analysis before mold cutting?

A5: Yes. We provide DFM reports and cost-reduction suggestions with every quote.

Contact Information

Want help reducing your mold development costs?

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

Our Service Highlights:

- Free DFM analysis and mold consulting

- Short-run and mass-production mold options

- Post-weld surface finishing and cosmetic QA

- One-stop service from tooling to final product

Cut costs—not quality. Let Prime optimize your metal part mold today.

We help buyers worldwide get better molds, lower costs, and faster lead times—all backed by 20+ years of ISO-certified experience.