Top 5 Custom Plastic Parts Suppliers: Industry Leaders in 2025

Industrial buyers in 2025 require plastic components that are precise, reliable, eco-conscious, and fast-delivered. This extended guide delves into the top five custom plastic suppliers, paints the broader resin landscape, explores future trends, and provides best practices for sourcing.

Who is the biggest plastic manufacturer in the US?

Resin giants in the U.S. include:

- Berry Global Group – Leading maker of packaging and injection-molded goods

- Formosa Plastics USA – Major producer of PVC, PE, and PP resins

- Westlake Corporation – America’s top LDPE and LLDPE manufacturer

- Inteplast Group – Specialist in film, sheet, and compound resins

Although they dominate resin production, none manufacture finished plastic parts—they supply to processors who serve industrial clients.

Who are the world’s biggest plastic producers?

By 2025, global resin leaders remain largely unchanged:

| Rank | Company | Key Products |

|---|---|---|

| 1 | Dow Inc. | Polyolefins, engineering resins |

| 2 | LyondellBasell | PE/PP technologies |

| 3 | ExxonMobil Chemical | Polyethylene, polypropylene |

| 4 | SABIC | General-purpose and specialty plastics |

| 5 | Eastman Chemical | Specialty/additive materials |

These industry titans influence resin pricing, availability, and innovation—which custom part manufacturers depend upon. But again, they don’t produce finished parts.

What is the future outlook of the plastic industry?

A. Shift to Eco-Friendly Materials

- Rising demand for bio-based plastics (like PLA, PHA) and post-consumer recycled (PCR) content due to global initiatives like the EU’s Circular Economy Action Plan.

- Industry leaders are investing in recycling technologies, promoting a circular supply chain.

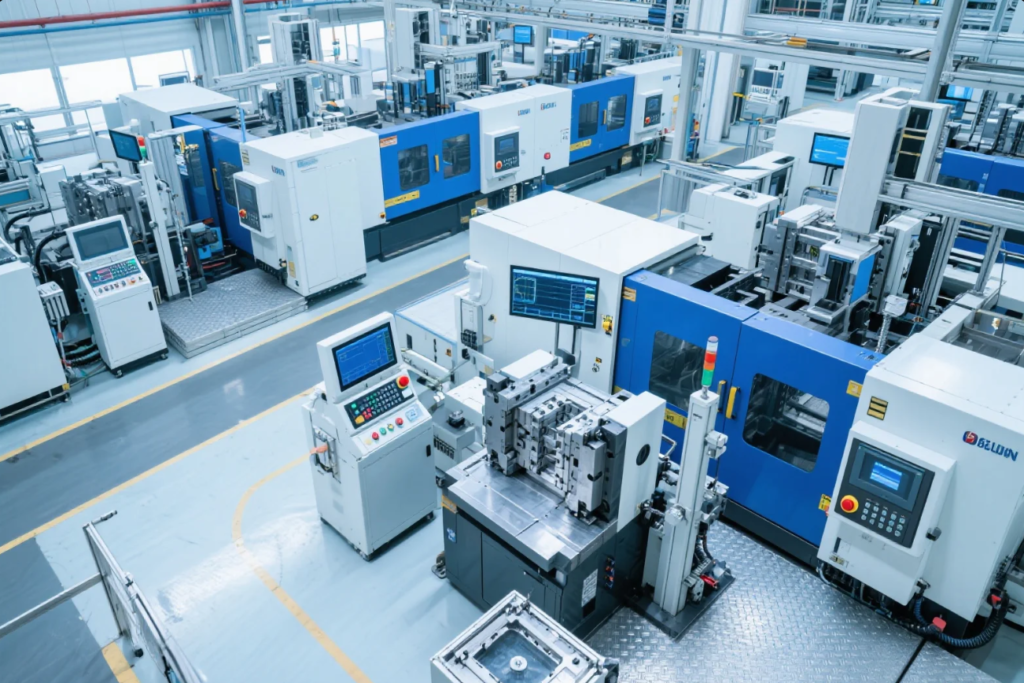

B. Smart Manufacturing and Digital Integration

- Adoption of Industry 4.0: IoT-integrated molding machines, automated inspections, and real-time monitoring are becoming mainstream.

- Digital platforms from Xometry and ProtoLabs provide instant quoting, design for manufacturability (DFM) checks, and 24/7 order tracking.

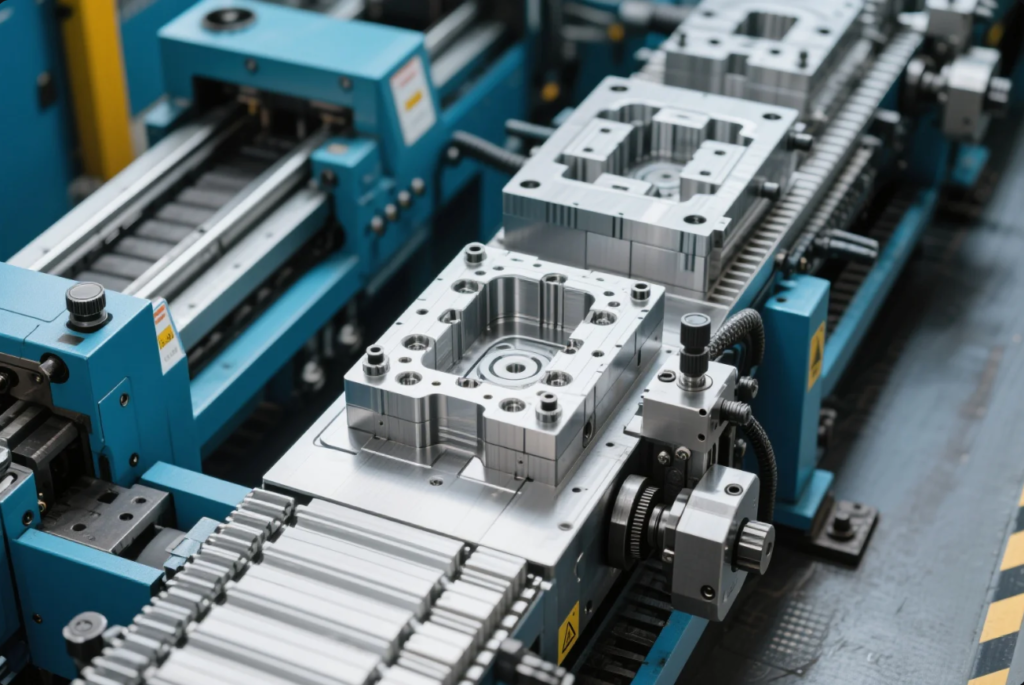

C. Advanced Manufacturing Techniques

- 3D printing for tooling, reducing mold development time.

- Use of conformal cooling channels to speed cycles and reduce warpage.

D. Regulatory Pressures

- Stricter chemical compliance globally—RoHS, REACH, food contact, medical regulations.

- Many custom suppliers are gaining ISO 14001, ISO 50001, or CE marking certifications.

E. Resilient Global Supply Chains

- Manufacturers are building dual-source tooling and creating regional mold bases to avoid disruption.

- Near-shoring to countries with stable logistics is growing in popularity.

Which company is best for plastic?

Evaluation Criteria:

- Certifications: ISO 9001, 14001, medical/food-grade where applicable

- In-house tooling: Enables rapid prototyping and tight turnarounds

- Material range: Commodity, engineering, flame-retardant, eco

- Factory capabilities: 30–800 ton presses, advanced QC, inspection

- DFM support: Tooling, flow, and cooling expertise

- Global export: Packaging, customs, and shipping services

- Technology adoption: Digital workflow, automation, smart tools

- Environmental responsibility: Licensing, recycling, sustainability

Standout Suppliers in 2025

Prime Custom Parts

- End-to-end service from design to global shipments

- In-house molds in 5–7 days, 60+ engineers on staff

- ISO 9001/14001 certified, multiple facilities worldwide

- Advanced post-processing (insert molding, overmolding)

- Real-time order tracking and live video feeds

Xometry

- Marketplace with injection molding, CNC, urethane casting

- Instant quoting, supply chain monitoring, digital DFM

- Quality certified sub-suppliers

- Strong logistics and quick RFQ response time

ProtoLabs

- Fast turn prototyping and low-volume runs

- Scientific molding approach, validated materials

- ISO 9001 and ISO 13485 (medical) certified

- Global service with strong North American presence

Fictiv

- Quality-engineered manufacturing through curated partners

- Handles molding, CNC, sheet, and urethane

- Closed-loop system for quality and traceability

Side-by-Side Comparison

| Feature | Prime Custom Parts | Xometry | ProtoLabs | Fictiv |

|---|---|---|---|---|

| ISO Certifications | 9001, 14001 | Varies by supplier | 9001, 13485 | Varies |

| Tooling Turnaround | 5–7 days (in-house) | Varies per partner | Rapid prototyping & tooling | Quick-turn tooling |

| Material Range | 15+ including specialty | Wide range offered | Common + medical resins | Select range |

| Press Range | 50–800 tons | Varies | Variety (30–500+ tons) | Dependent on site |

| DFM & Engineering Support | Full-service | Automated/manual | Hybrid | Consultative |

| Post-processing | Extensive options | Limited bundled options | Ink & assembly options | Customization per job |

| Smart Manufacturing | Real-time tools/data | Instant digital workflows | Data-driven molding | Digital partner portal |

Best Practices for Sourcing Custom Parts

- Use fully annotated 3D CAD files (e.g., STEP/IGES + GD\&T)

- Specify operating conditions: temperature, stress, UV, chemicals

- Ask for DFM input early, including moldflow simulation

- Run pilot batches to test form, fit, function, and appearance

- Tour factories or request video inspections to confirm production integrity

- Request certifications and quality documents (ISO, FAI, COC)

- Review logistics and packaging—especially for global shipments

- Consider multi-year agreements for cost stability and capacity access

- Check supplier sustainability initiatives like recycling programs or heat recovery systems

- Verify after-sale support—like spares, maintenance, and mold storage

FAQs

Q: Do big resin producers make finished parts?

No. Companies like Dow, SABIC, and ExxonMobil sell raw plastic—processors create the end-use products.

Q: How fast can tools be delivered?

With in-house tooling, 5–7 days is typical. Outsourcing increases time significantly.

Q: What tolerances can they hold?

Standard ±0.05 mm. Precision processes allow ±0.01 mm in controlled environments.

Q: Are sustainable plastics available?

Yes—many suppliers now offer bio-based, PCR, and food-safe grades. Ask for ASTM D6866 certification.

Q: Can I get a quote from CAD instantly?

Yes—Xometry and ProtoLabs provide automated quoting; Prime offers guided responses with live dashboards.

Conclusion

Resin giants—Dow, ExxonMobil, SABIC, LyondellBasell, and Eastman—set the foundation, but custom part excellence comes from smart suppliers. In 2025, leaders like Prime Custom Parts, Xometry, ProtoLabs, and Fictiv provide reliability, speed, technology integration, and sustainability—making them true industry leaders.

👇 Kickstart your project with Prime: email [email protected] or visit primecustomparts.com for free quotes and technical support.