Top 6 Custom Metal Mold Applications in Automotive, Aerospace, and More?

Manufacturers need precision. One-size-fits-all molds just don’t work.

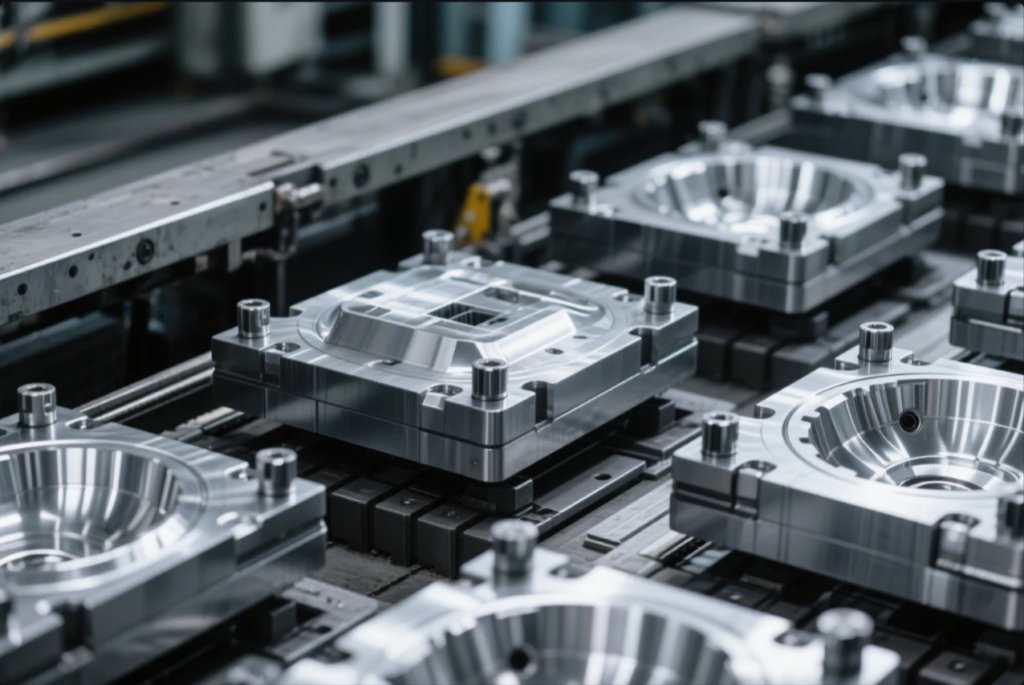

Custom metal molds are used in high-performance applications across automotive, aerospace, electronics, medical devices, and more. Precision, speed, and material compatibility make them essential in 2025. Companies that rely on generic molds fall behind.

Let’s break down where custom molds make the biggest impact—and how they drive global industry forward.

1. Automotive: Mass Production, Zero Defects

High-volume car production demands accurate, wear-resistant molds.

Custom metal molds shape parts like dashboards, bumpers, engine covers, and air vents. These components must withstand heat, impact, and wear—every time.

Tolerances are non-negotiable

At Prime, we work with Tier 1 automotive suppliers who demand molds that run 24/7 with ±0.01mm precision. Materials like H13 steel and copper inserts handle high pressure and fast cycles.

| Component | Mold Type | Mold Feature |

|---|---|---|

| Bumper Brackets | Die-cast mold | High impact resistance |

| Dashboard Panels | Injection mold | Texture finish, heatproof |

| Gear Housing | CNC machined inserts | Tight tolerances |

2. Aerospace: Lightweight and High-Strength Components

Weight-to-strength ratio is critical in aviation.

Molds for aerospace parts must accommodate exotic alloys like titanium and aluminum-lithium. Accuracy is key for wings, brackets, housings, and sensors.

Aerospace clients expect excellence

We use 5-axis machining and thermal flow analysis to meet standards set by companies like Boeing and Airbus. Internal cooling systems prevent hot spots during casting.

| Part | Requirement | Prime Solution |

|---|---|---|

| Wing Bracket | Lightweight, strong | Aluminum mold, low-porosity |

| Actuator Housing | Vibration resistant | Fine-grain alloy, EDM finish |

| Sensor Baseplate | Thermal stable | Multi-cavity, CMM verified |

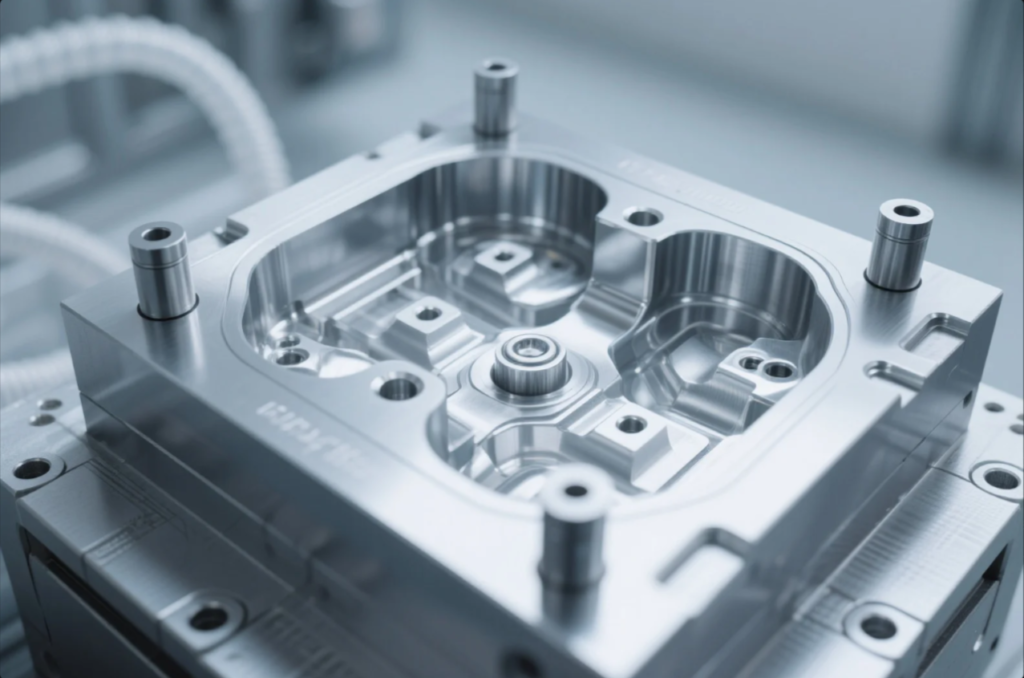

3. Medical Devices: Micro Tolerances, Cleanroom Molds

Patient safety starts with precision tools.

Medical injection molds must be contaminant-free, ultra-precise, and made in certified environments. Common applications include syringes, implants, tubing connectors, and device housings.

Every micron counts

Prime molds medical parts with tolerances as tight as ±0.005mm using materials like S136 stainless steel. We support ISO 13485 compliance and cleanroom-compatible finishes.

| Product | Mold Requirement | Prime Approach |

|---|---|---|

| Syringe Barrel | Crystal clear, no flash | Mirror-polished cavity |

| Implant Shell | Biocompatible, accurate | Stainless steel, micro-CNC |

| Device Clip | Snap-fit, high volume | Multi-cavity hot runner |

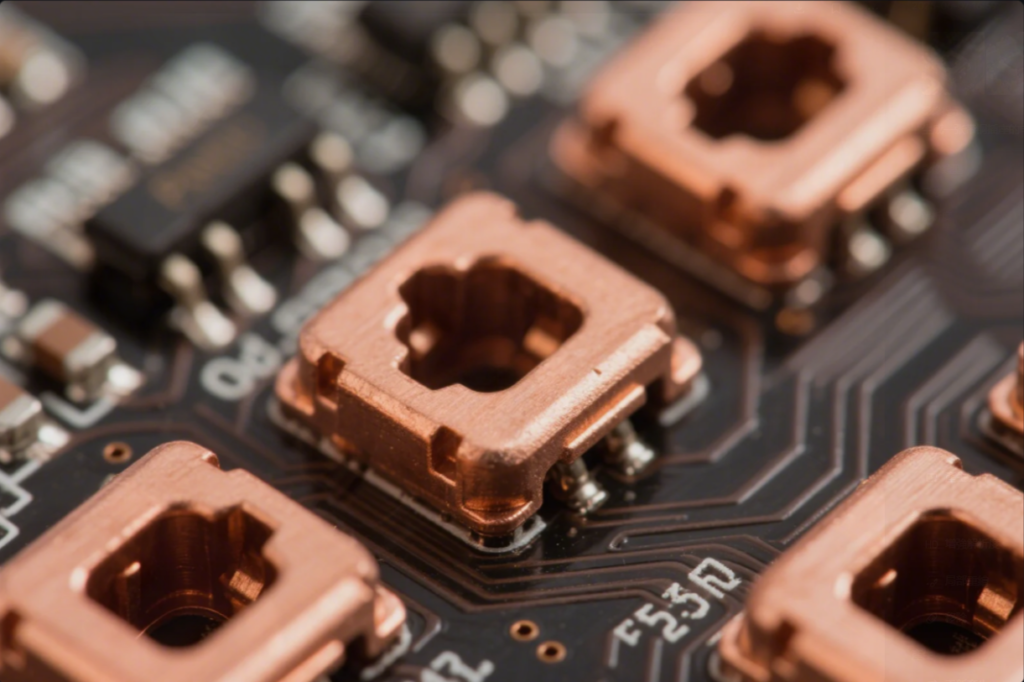

4. Electronics: Heat-Sensitive, High-Volume Molding

Phones, laptops, and EV components need complex molds.

Electronic housings require precise venting, material flow control, and heat-dissipating designs. Volume runs into millions.

Mold performance = product reliability

We’ve built molds for Foxconn suppliers, especially for smartphone frames and cable overmolds. Beryllium copper is often used to dissipate heat in tight spaces.

| Component | Challenge | Prime Feature |

|---|---|---|

| USB Connectors | Tight insert fit | EDM machined cavities |

| Battery Casings | Thermal control | Copper-cooled inserts |

| Touch Panel Frames | Smooth edge, no flash | Slide cores, gas vents |

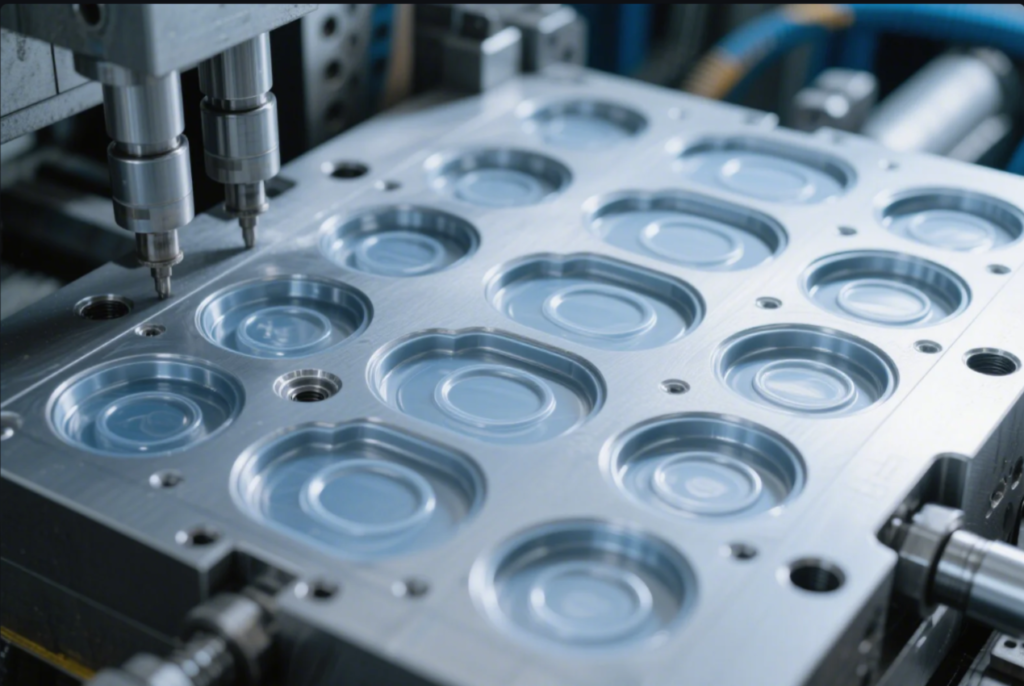

5. Packaging: Speed and Scalability

Fast-moving consumer goods need fast mold cycles.

Plastic caps, trays, containers, and wraps require cycle times under 3 seconds. Mold design must minimize wear and maximize ejector efficiency.

Every second matters

For packaging clients like Nestlé, we build 16–64 cavity molds with hot runners and quick-change inserts. Hardened steel guarantees long life even after 1 million cycles.

| Package Type | Volume Level | Prime Design Element |

|---|---|---|

| Water Bottle Caps | High-speed | Balanced runner, auto-eject |

| Food Trays | Thin-wall, large surface | Flow simulation tested |

| Cosmetic Closures | Tight tolerances | Polished multi-cavity |

6. Home Appliances: Durable, Complex Shapes

Appliance casings, knobs, and brackets must combine strength and beauty.

Molds for home appliances handle thick-wall parts with textured surfaces. Mold life and appearance consistency are key.

From design to performance

We’ve supported projects for Whirlpool and Haier. Molded parts require complex undercuts and multiple ejection systems.

| Appliance Part | Mold Functionality | Prime Technology |

|---|---|---|

| Control Panel | Aesthetic surface | Texture-etched molds |

| Handle Brackets | Load bearing | Reinforced insert molding |

| Internal Covers | Electrical safe | Flame-retardant design |

FAQs

Who is the father of injection molding?

John Wesley Hyatt, who invented the injection molding process in the late 1800s.

Are mold makers in demand?

Yes. According to U.S. Bureau of Labor Statistics, skilled mold makers remain in high demand due to the rise in precision manufacturing.

Which country is best for injection molding?

China leads in both price and production capacity. However, Germany, the USA, and Japan are top for precision.

What companies do injection molding?

Some top mold makers include Husky Injection Molding Systems, RJG Inc., and Prime Custom Parts.

Conclusion

Custom metal molds are vital for high-performance industries—from automotive to aerospace and beyond.

Need ISO-certified, high-precision molds for your industry?

📩 Contact us: [email protected]

🌐 Learn more: https://primecustomparts.com

At Prime, we deliver consistent results, competitive pricing, and quick lead times—globally.