Top 7 Custom Metal Mold Design Tips for Precision and Durability: Boost Performance and Reduce Rework

Even the most advanced mold shop can’t fix poor design.

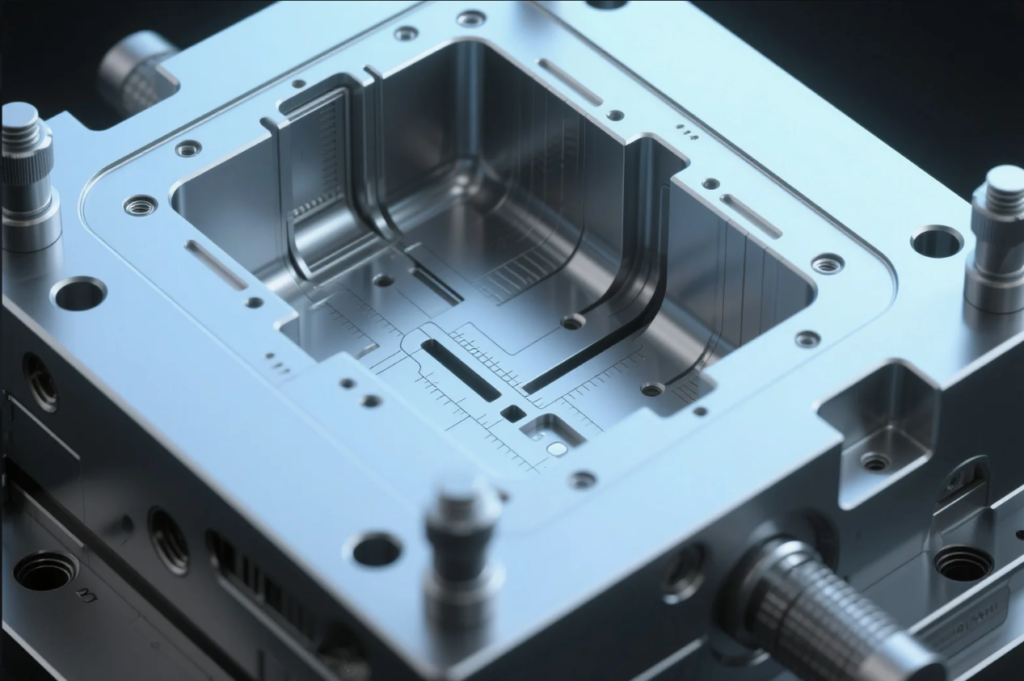

This article covers 7 expert-level custom metal mold design tips to ensure part accuracy, extended mold life, and efficient production. These practices are essential for engineers and buyers sourcing molds for CNC machining, die casting, MIM, or stamping.

By applying these proven mold design principles, you can save cost, prevent defects, and accelerate delivery—all while improving part performance.

What is the rule of thumb for injection molding?

Design affects cycle time, part strength, and mold life.

The top design rule of thumb is to maintain even wall thickness—usually between 1–3 mm. Use 1–2° of draft on vertical faces, add corner radii of at least 0.5 mm, and avoid sharp transitions that cause internal stress or warping.

Key Guidelines

| Feature | Best Practice |

|---|---|

| Wall Thickness | 1.5 mm (standard for MIM) |

| Draft Angles | 1–2° minimum |

| Radii | 0.5 mm internal corners |

| Gate Placement | Closest to thickest sections |

Visit Protolabs’ design guide for more.

Prime uses Moldex3D to simulate and optimize every mold before cutting steel.

What is the best steel for molds?

Your mold’s lifespan depends on your steel choice.

H13 is the best steel for molds exposed to heat and pressure—especially in die casting and metal injection molding. P20 is used for low-volume plastic or soft metal molds. S7 is preferred for stamping dies due to its impact resistance.

Steel Comparison Table

| Steel Type | Hardness (HRC) | Best Used For |

|---|---|---|

| H13 | 48–52 | Die casting, MIM, high-wear |

| P20 | 28–32 | Plastic molding, prototyping |

| S7 | 54–58 | Stamping, shear-heavy dies |

| SKD61 | 50–55 | Precision tools, Asia market |

For in-depth selection, see Bohler Steel’s datasheets.

Prime selects steels based on cycle count, part material, and corrosion risk.

How much do mold designers make in the US?

Tooling design remains one of the most in-demand specialties.

Mold designers in the U.S. make \$55,000 to \$100,000 annually. Salaries vary by industry (automotive, aerospace, medical), software skills (SolidWorks, NX, CATIA), and region. Demand for high-tolerance design continues to rise.

Salary Averages (2025)

| Position | Annual Salary (USD) |

|---|---|

| Entry-Level Designer | \$55,000 |

| Experienced Designer | \$75,000 |

| Senior/CAM Programmer | \$90,000+ |

Visit Glassdoor or Talent.com for real-time updates.

Prime’s in-house design team specializes in complex mold geometries, undercuts, and dual-material designs.

What is the minimum thickness for metal injection molding?

Too thin, and the metal won’t flow. Too thick, and you waste material.

The minimum wall thickness for MIM parts is 0.3 mm. However, for best sintering outcomes and consistent shrinkage, walls are typically kept between 0.8–1.5 mm. Thin walls must be uniform and properly supported.

MIM Thickness Guidelines

| Feature | Recommendation |

|---|---|

| Thin Walls | ≥ 0.3 mm |

| Optimal Range | 0.8–1.5 mm |

| Wall Variance | Keep ≤ 20% variation |

| Rib Design | Max 60% of wall size |

For guidelines, check INDO-MIM’s design resources.

At Prime, Top 7 Custom Metal Mold Design Tips for Precision and Durability,we apply sintering simulations to predict warping in advance—saving your first-shot success.

FAQs

Q1: Can undercuts be designed into metal molds?

A1: Yes, but they need lifters or slides, which increase cost and complexity.

Q2: What surface finishes can be applied to metal molds?

A2: EDM texturing, SPI finishes, mirror polishing, or bead blasting.

Q3: Can you mold threads directly?

A3: Internal threads can be molded with cores; external threads often need post-machining.

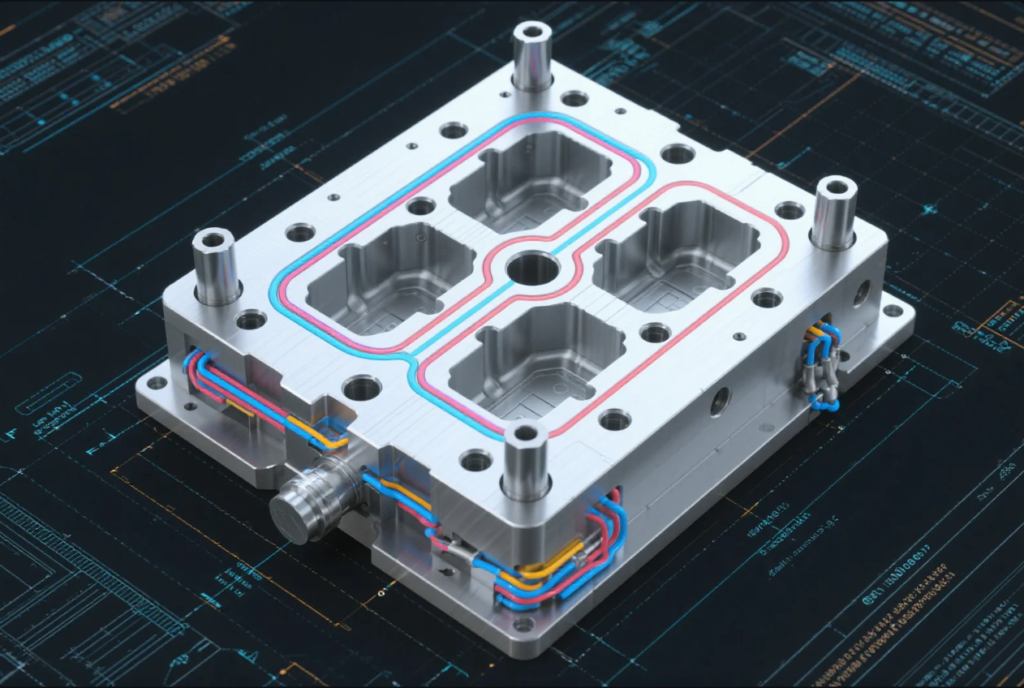

Q4: Does Prime provide conformal cooling?

A4: Yes, for select high-volume molds using 3D-printed inserts or laser sintered cores.

Q5: What certifications does Prime hold?

A5: ISO 9001 for quality management, and CE-compliant packaging for export markets.

Contact Information

Let Prime help you design custom metal molds with real precision.

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

Our Services:

- Full CAD/CAM mold design with DFM

- ISO-certified mold fabrication

- Custom solutions for MIM, stamping, casting

- On-time delivery to 30+ countries

Get your custom mold built right from the start.

Partner with Prime for smarter designs, longer tool life, and faster time-to-market.