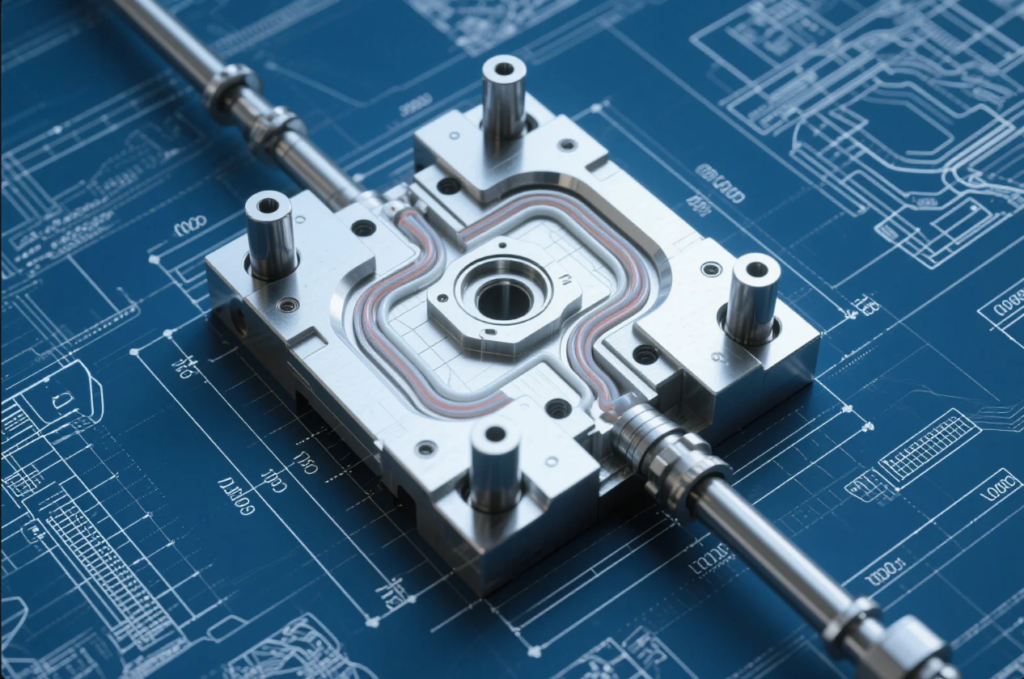

Top 7 Factors to Consider When Designing Custom Molds for Metal Parts: How to Get It Right from the Start?

Many molds fail not because of tooling—but because of poor design.

This article outlines the 7 key factors you must consider when designing custom molds for metal parts. From draft angles to gating, we cover what matters most for durability, efficiency, and part quality.

Avoid costly rework, reduce lead time, and improve tooling ROI by applying these proven design principles before you start cutting steel.

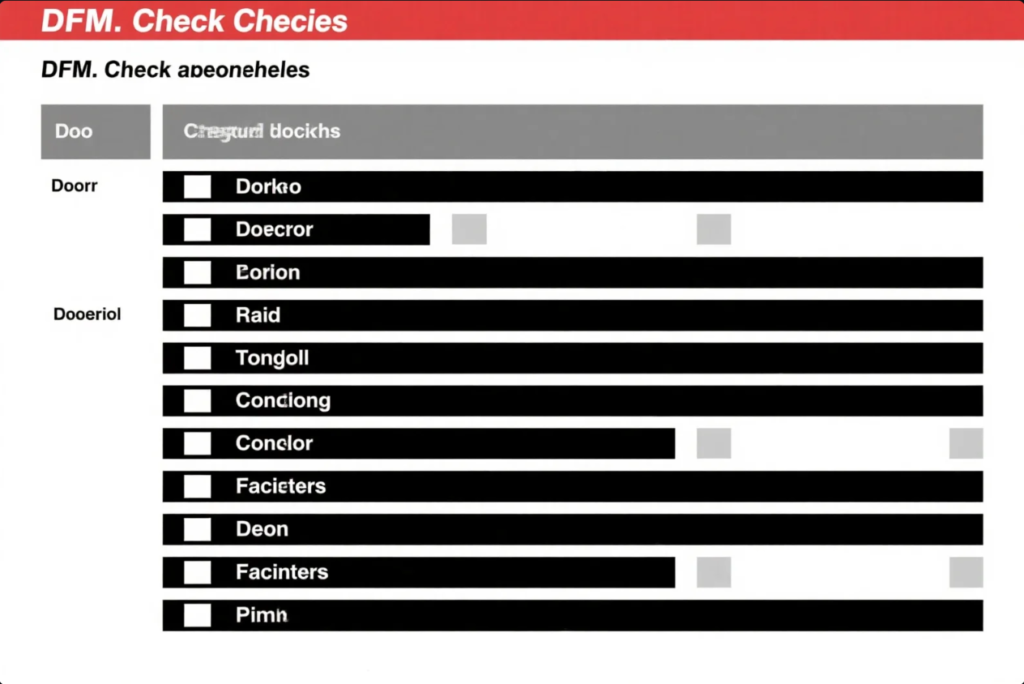

What are the factors which should be considered before designing a casting?

A good mold starts with the right casting design. Ignoring early factors leads to uneven filling, defects, or expensive revisions.

Before designing a casting, you must consider part geometry, shrinkage, flow pattern, wall thickness, and ejection needs. A detailed DFM (Design for Manufacturing) review is essential.

Key Pre-Design Considerations

| Factor | Why It Matters |

|---|---|

| Part Geometry | Complex shapes increase mold complexity |

| Shrinkage | Metal contracts differently per alloy |

| Wall Thickness | Non-uniform walls cause warping |

| Draft Angles | Needed for smooth part ejection |

| Parting Lines | Affects flash and tooling alignment |

At Prime, every custom mold starts with a full DFM analysis—including warpage simulation, flow path testing, and cost-risk tradeoffs.

What are the points which a designer should consider when going for a casting process?

Metal casting isn’t just about filling a cavity—it’s about controlling cooling, flow, and shrink.

A designer must focus on mold layout, alloy selection, cooling strategy, gating and runner system, and post-processing allowances. These influence cost, quality, and lead time.

Top Design Points to Remember

- Choose an appropriate casting process (sand, die, investment)

- Design for smooth metal flow with fillets and rounded edges

- Maintain uniform wall thickness where possible

- Add machining or finishing allowances to final dimensions

- Place ejector pins and vents strategically

Use the NADCA die casting design guide to check standards by part size and weight.

Prime engineers apply these rules on every mold project. We ensure your design isn’t just printable—it’s castable.

What are the five-five metal casting processes?

With so many casting methods, which one fits your part?

The 5 most common metal casting processes include sand casting, die casting, investment casting, centrifugal casting, and permanent mold casting. Each suits different shapes, metals, and tolerances.

Metal Casting Comparison Table

| Process | Mold Type | Best For | Key Advantage |

|---|---|---|---|

| Sand Casting | Expendable | Large, low-precision parts | Cheap tooling |

| Die Casting | Reusable | Aluminum/zinc parts, high volume | Tight tolerance, smooth surface |

| Investment Casting | Ceramic (lost wax) | Complex shapes, stainless steel | Excellent detail, no flash |

| Centrifugal Casting | Rotational mold | Cylindrical parts, pipes | High density, no voids |

| Permanent Mold Casting | Steel/aluminum | Medium volume, aluminum | Stronger parts than sand casting |

At Prime, we help clients pick the right process based on design geometry, metal type, and budget. We produce both prototype and mass production molds.

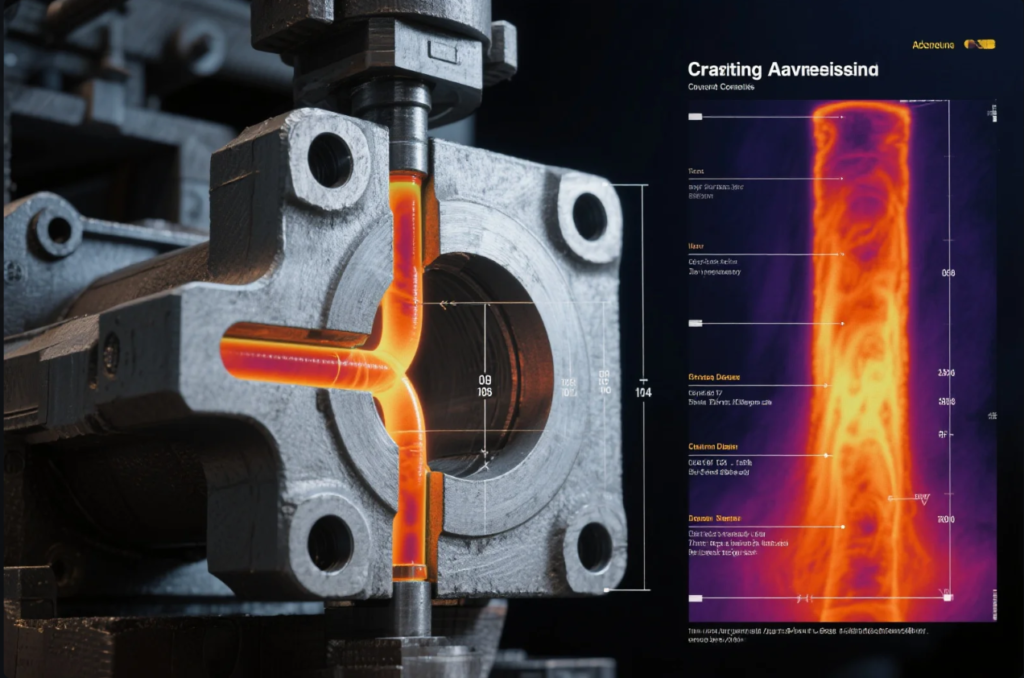

What are the considerations of casting design?

Even after choosing the method, smart casting design makes the difference between success and scrap.

Key considerations in casting design include draft angles, fillets, risers, mold material compatibility, and thermal behavior. Each factor impacts mold life and casting quality.

Advanced Design Considerations

| Consideration | Why It’s Important |

|---|---|

| Risers & Gating | Controls metal flow and shrinkage |

| Fillets & Corners | Prevents stress concentration and cracking |

| Core Placement | Enables hollow or internal geometry |

| Venting Strategy | Avoids gas entrapment |

| Thermal Gradients | Ensures even cooling and part integrity |

Check out EngineeringToolBox’s casting calculators to plan gates and wall thickness.

At Prime, we simulate all these elements using Moldflow and SolidWorks Flow Sim tools before production, minimizing the chance of defects or costly tool revisions.

FAQs

Q1: How much draft should I include in my casting design?

A1: Typically 1–3°, but more is needed for textured surfaces or deep cavities.

Q2: Can you design molds for die casting and MIM?

A2: Yes. We specialize in both high-pressure die and metal injection molding tools.

Q3: What’s the tolerance achievable in metal casting?

A3: Depends on the method—die casting can achieve ±0.05 mm, while sand casting is ±0.5 mm.

Q4: Can I rework an existing mold to improve performance?

A4: Yes, we offer mold refurbishment and design upgrades for older tooling.

Q5: How fast can Prime deliver a mold?

A5: Simple aluminum molds: 10–15 days; full steel or MIM molds: 25–30 days.

Contact Information

Need expert support for designing your next metal mold?

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

We provide:

- Full DFM and casting analysis reports

- Mold design and production in-house

- MIM, die cast, and sand cast mold expertise

- Fast lead times and ISO 9001 QA documentation

Avoid costly mistakes—design your mold right with Prime.

With 20+ years of tooling experience, we help global manufacturers design high-performance molds that meet specs and exceed expectations.