Top 7 Precision Forging Manufacturers for OEM and Heavy‑Duty Applications?

Which is the largest forging company in the world?

Bharat Forge stands as the world’s largest forging firm, headquartered in Pune, India. With 14 plants and over 17,000 employees, Bharat Forge generated approximately \$1.5 billion in revenue in 2024, serving sectors like automotive, aerospace, energy, and defense.

Capabilities & Highlights:

- Hydraulic presses up to 12,000 kN

- Ring rolling, CNC finishing, NDT labs

- Certifications: ISO 9001, IATF 16949, NADCAP

- Advanced R\&D and 100+ global patents

What is another name for precision forging?

Precision forging is also known as “near‑net‑shape forging” or “closed‑die precision forging.” When performed under synchronized temperature control, it’s sometimes called “isothermal forging.” These terms denote processes delivering ±0.05 mm tolerance and aiming for minimal or no machining post-forging.

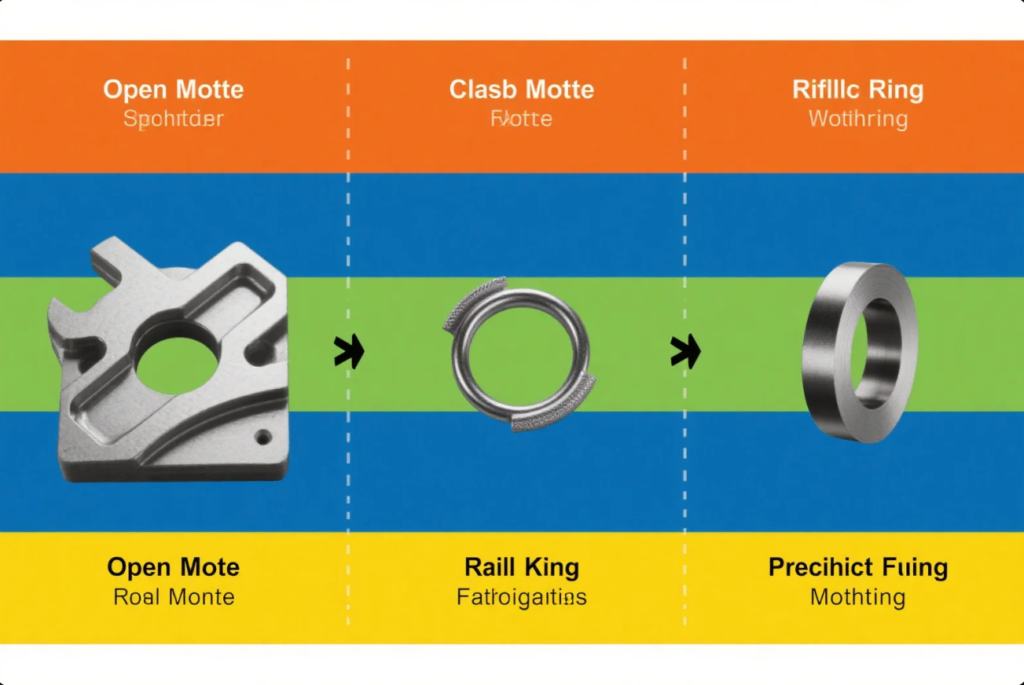

What are the 4 types of forging?

Below are the four primary forging techniques used in heavy-duty and OEM component production:

-

Open‑Die Forging

- Used for large parts like gears & shafts

- Tolerance: ±0.5 mm; flexible, low tooling cost

-

Closed‑Die Forging

- Ideal for high-volume, high-precision components

- Tolerance: ±0.1 mm; higher tooling cost

-

Rolled‑Ring Forging

- Produces rings for turbines and flanges

- Tolerance: ±0.3 mm; excellent grain structure

-

Press/Precision Forging

- Uses high-speed presses for tight tolerance parts

- Tolerance: ±0.05 mm; suitable for aerospace-engine parts

What is DFM for forging?

Design for Manufacturability (DFM) in forging helps optimize parts for cost, quality, and manufacturability.

Key DFM Guidelines:

- Maintain uniform wall thickness

- Avoid sharp corners; use fillets

- Incorporate draft angles for mold release

- Use ribs judiciously for strength

- Simplify geometry to reduce machining

Optimized design reduces tool wear and production time, saving up to 30% of cost and post‑machining efforts.

Top 7 Precision Forging Manufacturers

1. Bharat Forge (India)

Largest global capacity, comprehensive closed‑die and ring‑rolling expertise, NADCAP approved, heavy-duty OEM focus.

2. Thyssenkrupp Forging (Germany)

Advanced automated forging lines and smart factory integration. Learn more: thyssenkrupp.com/en/forging.

3. Finkl / Worthington Forged Steel (USA)

Exceptional open‑die and closed‑die capabilities in tool steel and alloy forgings for energy and aerospace.

4. Scot Forge (USA)

High-precision forging with custom alloy solutions, extensive heat-treatment and machining services.

5. Shandong Prime International (China)

Prime delivers full-service forging, CNC machining, and stamping. With ISO certification, 10 automated lines, low MOQ, and rapid delivery, it serves global OEMs.

6. Kobe Steel (Japan)

Forging specialist in high‑precision titanium and nickel alloys for aerospace sectors.

7. Farinia Group (France)

Integrates precision forging and digital control systems, with aerospace-grade production standards.

Future Trends & Buyer Checklist

Key Industry Trends:

- Factory automation with robots and smart presses

- IIoT performance sensors and AI fault prediction

- Use of specialty alloys (Ti, Al 7075, super‑duplex steel)

- Green forging via induction heating and solar plants

Buyer’s Sourcing Checklist:

✅ Confirm forging type aligns with part design

✅ Validate ISO 9001, IATF 16949, NADCAP certifications

✅ Inquire about automation and data-tracing capabilities

✅ Validate alloy range, heat‑treatment, and NDT capacity

✅ Check export packaging quality and delivery timelines

Conclusion & Call to Action

Precision forging ensures reliability in critical OEM and heavy-duty applications. The top seven manufacturers described here lead in technology and quality—especially China’s Shandong Prime International, offering turnkey precision forging with fast responses and global logistics support.

📧 Contact Prime Today: [email protected]

🌐 Visit Website: primecustomparts.com

Request quotes, submit CAD files for DFM review, and secure reliable execution with packaging and delivery tailored to your industrial needs.

One Response