Top 8 Custom Metal Mold Applications for High-Volume Manufacturing in 2025?

Manufacturers in 2025 face growing pressure: more output, less waste, and tighter tolerances. For that, they need custom molds designed for efficiency.

Custom metal molds are the foundation of high-volume production. They enable fast, repeatable, cost-effective manufacturing across industries.

In this guide, I’ll share the top applications, latest materials, cost structures, and machines shaping the future of mold-making.

What is the future of injection Moulding?

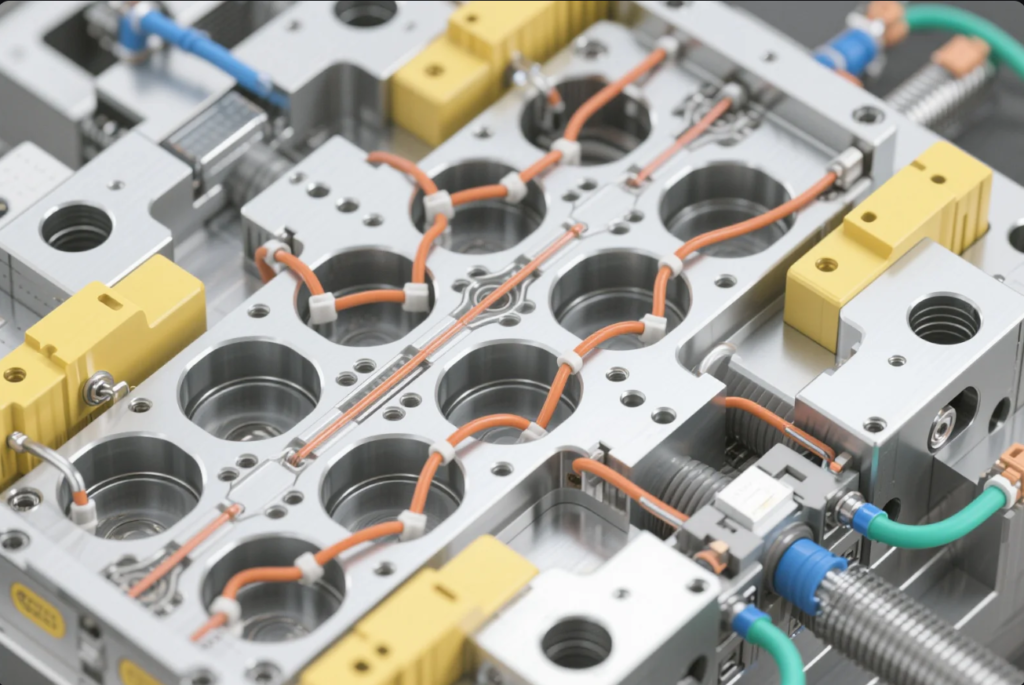

Injection molding is no longer just about cavities and cycles. It’s entering a digital, data-driven phase where molds are smart, connected, and optimized in real time.

In 2025, injection molding is shaped by automation, real-time monitoring, and zero-defect goals.

Major Trends Driving Change

| Trend | Impact |

|---|---|

| Smart Molds with Sensors | Live data on pressure, temp, and fill balance |

| AI-Based Predictive Systems | Anticipate defects before they happen |

| Closed-Loop Automation | Robots + vision systems = lights-out production |

| Micro-Injection Molding | For sensors, connectors, and wearables |

| Sustainability Engineering | Focus on recyclable tools and low-energy cycles |

At Prime, we produce high-cavitation injection molds with built-in thermocouple ports and sensor channels. One electronics client in South Korea achieved 98.5% first-pass yield after integrating our molds with ENGEL e-motion series.

For more on the tech shift, see Plastics Today’s 2025 injection forecast.

What are the new materials being used to make Moulds nowadays?

High-volume molds face immense heat, pressure, and abrasion. That’s why new alloys and composites are redefining tool steel.

Today’s mold makers use materials engineered for longevity, thermal performance, and tight tolerances.

Popular Mold Materials in 2025

| Material | Key Features | Ideal For |

|---|---|---|

| H13 Tool Steel | Heat-resistant, long cycle life | Industrial, automotive molds |

| Maraging Steel | Ultra-strong, easy to machine, no distortion | Aerospace-grade components |

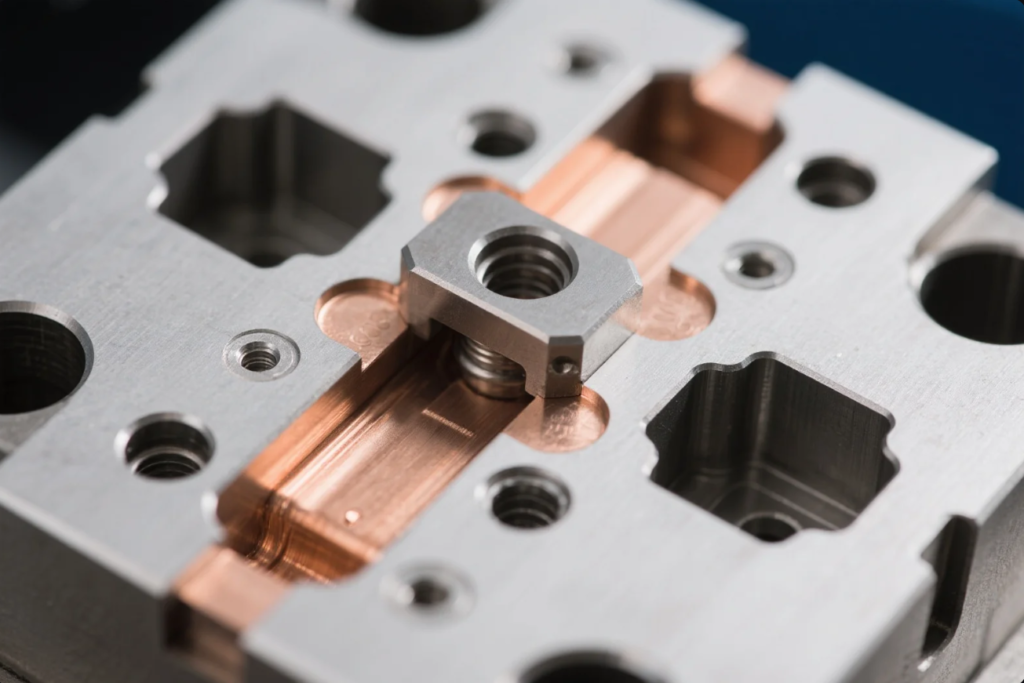

| Beryllium Copper | Rapid cooling, high thermal conductivity | Sliders, inserts, micro-tooling |

| Tungsten Alloys | Wear-proof under high pressure | Powder injection, glass-filled resin |

| Stainless 420 | Corrosion-resistant, easy to polish | Medical & food-grade parts |

We source from top-grade material suppliers like ASSAB and recommend insert modularity for maintenance flexibility. Our clients save 30–50% in total mold lifecycle cost with modular tool systems.

How much does it cost to mold a product?

Tooling costs can be intimidating—but they amortize quickly in mass production.

Custom mold pricing in 2025 ranges from \$1,000 to over \$150,000, based on size, material, finish, and volume.

Sample Pricing Breakdown

| Mold Type | Cost Range (USD) | Best Use Case |

|---|---|---|

| Prototype CNC Mold | \$1,000 – \$4,000 | Functional testing, R\&D |

| Single-Cavity Steel Mold | \$5,000 – \$15,000 | Consumer electronics, small appliances |

| Multi-Cavity H13 Mold | \$20,000 – \$100,000+ | High-speed caps, medical parts |

| Insert Molds | \$8,000 – \$30,000 | Overmolded connectors, hybrid units |

We helped a German home appliance client reduce their per-unit cost by \$0.22 by shifting from 4-cavity to 16-cavity tooling—fully recovered mold cost in under 3 months.

Try the Xometry mold cost calculator to forecast your ROI.

What machine makes molds?

Mold building is a blend of art and machine precision. From rough machining to final finishing, multiple machines ensure micron-level detail.

Top machines for mold making include CNC mills, EDM machines, high-speed drills, and wire cutters.

Equipment Lineup in Modern Mold Shops

| Machine Type | Role in Mold Making |

|---|---|

| CNC 3/5-Axis Milling | Core/cavity shaping, insert milling |

| EDM Sinker | High-precision ribs, logos, sharp features |

| Wire EDM | Cutting hard electrodes and fine contours |

| Surface Grinder | Achieving mirror-flat plate contact surfaces |

| Coordinate CMM | Ensuring ±0.005 mm part accuracy |

Prime’s mold division includes 15+ CNC machines and 8 EDM centers, operating 24/7 for global clients. We also run pre-cut simulations using CAM software to eliminate first-article surprises.

Learn more about mold machinery on Modern Machine Shop.

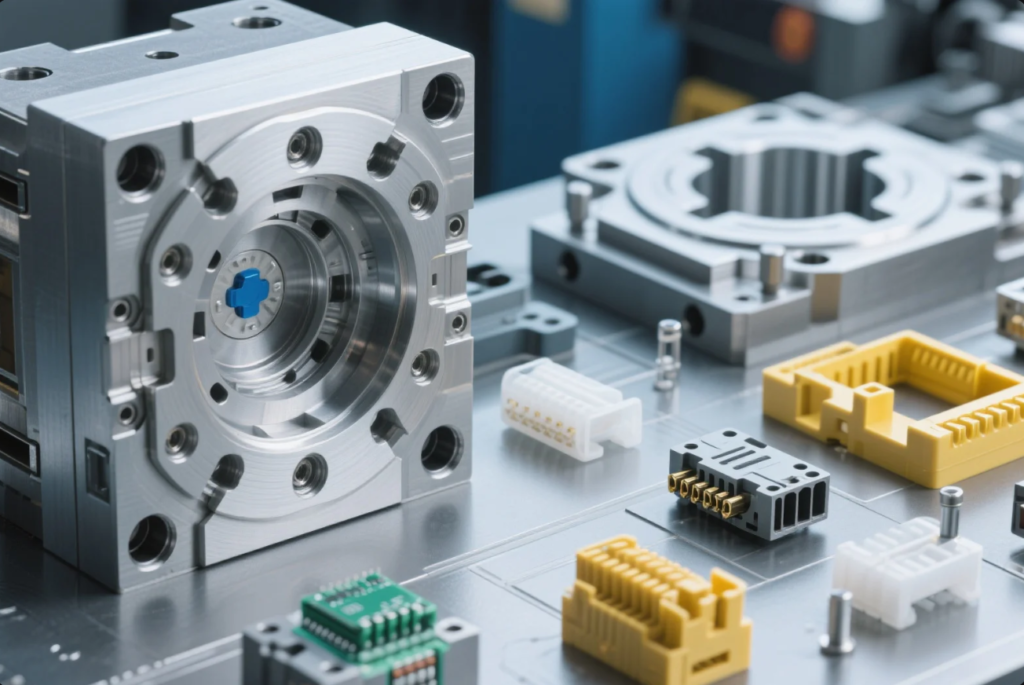

Top 8 Custom Mold Applications in 2025

Custom metal molds aren’t just for plastic spoons. In 2025, they’re shaping critical components across multiple sectors.

Top Applications

- Medical Devices – Syringe barrels, implant tools, inhaler casings

- Consumer Electronics – Power bank enclosures, button modules

- Automotive Connectors – ECU housings, cable harness clips

- Household Appliances – Water filter parts, gear housings

- Packaging Closures – Bottle caps, dispenser valves

- Smart Wearables – Watch cases, sensor covers

- Industrial Tools – Safety lock handles, switch covers

- Telecom Components – Antenna bodies, optical frames

We helped a U.S.-based wearable tech brand scale from 50 to 500,000 smartwatch parts per quarter—using a modular H13 multi-cavity mold with quick ejector pins.

FAQs

1. What’s the typical lead time for a custom mold?

Rapid molds: 7–10 days. High-cavity steel molds: 20–40 days, including testing.

2. Do you offer post-delivery support?

Yes. Our team provides lifetime technical guidance, re-polishing, and repair parts.

3. Can Prime handle RoHS, CE, and ISO-compliant exports?

Yes. We support global certification standards and ship to 30+ countries.

4. Do you provide mold flow and cooling analysis?

Absolutely. We run Moldex3D and Autodesk Moldflow for every DFM package.

5. What file formats do you support for mold design?

STEP, IGES, Parasolid, SolidWorks, DXF—and we also help optimize poor CAD files.

Conclusion

High-volume manufacturing success starts with mold quality. At Prime, we engineer molds that last, scale, and pay back fast.

🔧 Over 20 years of B2B metal mold experience

🚀 Rapid lead time + global logistics

📊 Free consultation + DFM reports

📞 Email: [email protected]

🌐 Website: https://primecustomparts.com

Let’s scale your production—one precision mold at a time.