Top 8 Custom Plastic Parts Manufacturers for High‑Performance Components in 2025

Who is the biggest plastic manufacturer in the US?

Leading U.S. resin suppliers shape the raw material market:

- Berry Global Group – A global leader in engineered packaging and injection-molded products.

- Formosa Plastics USA – Produces polypropylene, polyethylene, and PVC at scale.

- Westlake Corporation – America’s top LDPE and LLDPE producer.

- Inteplast Group – Specialist in films, sheets, and compounds.

These giants supply resin but rely on custom processors for finished parts.

What company is the largest plastic producer in the world?

2025 global resin rankings:

- Dow Inc. – Polyolefins, advanced resins across industries.

- LyondellBasell – PE/PP leader with tech licensing.

- ExxonMobil Chemical – Major petrochemical supplier.

- SABIC – Powerhouse in global polymer markets.

- Eastman Chemical – Specialty and additive materials.

- Westlake – Significant North American resin capacity.

- Amcor – PET packaging leader.

Recent industry reports show Dow posted \$51 billion in 2024 revenue .

Which plastic brand is best?

Leading Resin Brands

- Dow – Known for materials like DOWLEX™ and STYRON™ used in automotive and electronics.

- LyondellBasell – Provides PRO-fax® and MILLENNIUM™ resins.

- SABIC – Offers LEXAN™, ULTRASON™ flame-retardant resins.

- ExxonMobil Chemical – Supplies polyolefins under the brand name EXACT™, VISTAMAXX®.

Custom Manufacturer Highlights

- Prime Custom Parts (china-based) – Innovative, in-house tooling in 5–7 days, extensive export network.

- Xometry – Frictionless quote-to-order platform.

- ProtoLabs – Rapid prototyping and low- to mid-volume production.

- Fictiv – Transparency-focused contract manufacturer.

- Protolux Plastics – Specializes in aerospace-certified production.

- FormFit Plastics – Cleanroom medical molding expert.

- TechSource Molding – Micro-molding and tight tolerance experts.

- ProMold Solutions – Engineering-grade industrial plastics.

How do you get a plastic part manufactured?

Follow this comprehensive 8-step process:

- Submit 3D CAD with annotations (STEP, IGES, JST).

- Provide specifications like usage conditions, finish, and certifications.

- Request DFM & material proposal, including resin recommendations.

- Tooling: begin with prototype tooling, advance to production molds.

- Receive first article parts (T0/T1) for validation.

- Conduct pilot production (50–500 pcs) for testing.

- Scale up to mass production, tracking SPC data.

- Package & ship with documentation – FAI, COC, SPC, export compliance.

All top suppliers offer end-to-end support and consultation.

What industries use high-performance custom plastic parts?

- Aerospace – Lightweight, advanced composites, flame resistance (Certified to FAR 25.853).

- Medical Devices – FDA and ISO 13485 standard compliance.

- Automotive – Heat-resistant and impact-resistant components.

- Electronics – EMI shielding, insulating solutions.

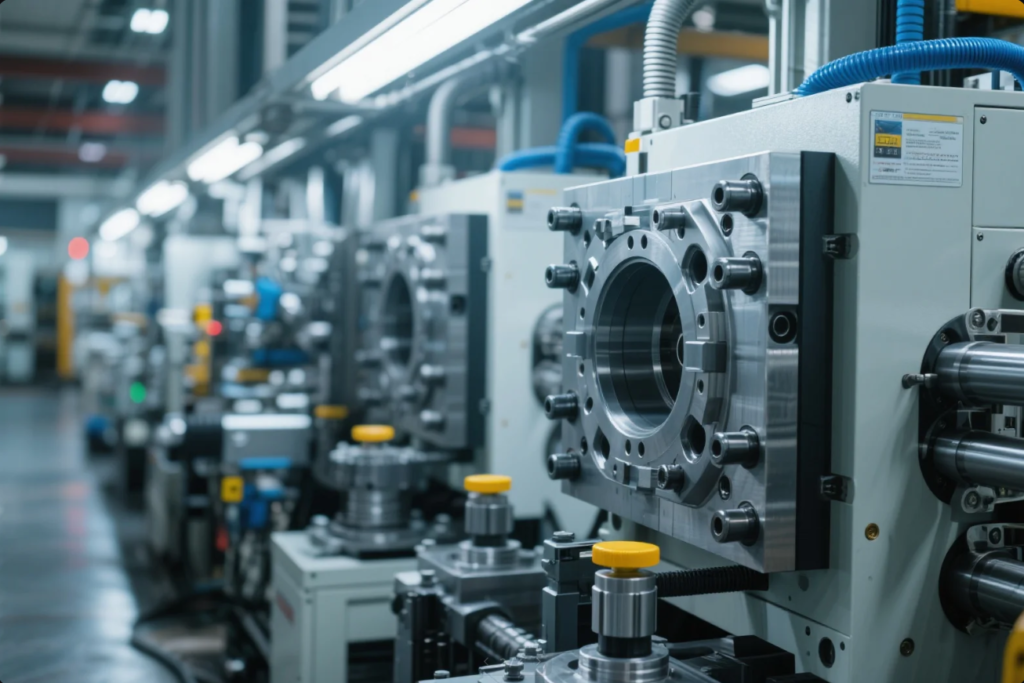

- Industrial Machinery – Durable gears, fluid systems, safety parts.

- Energy/Oil & Gas – Chemically resistant valves and connectors.

See OEM case studies on Dow and SABIC.

What makes a supplier ideal for high-performance parts?

- Certifications: ISO 9001, 14001, 13485, UL, RoHS, FDA.

- High-end materials: PEEK, PPS, PVDF, medical-grade polymers.

- Precision tooling: Tight tolerance (±0.01 mm) hardened steel molds.

- Advanced quality controls: Controlled SPC, full CMM inspections, FAI.

- Post-production services: Overmolding, assembly, insert molding.

- Smart factory tools: IoT sensors, real-time dashboards.

- Export infrastructure: Crates, bonded warehouses, customs agreements.

- Sustainability programs: Recycling, PCR materials, energy-efficient plants.

Best practices when sourcing custom plastic parts

- Provide complete CAD details and materials conditions.

- Describe the technical application environment.

- Request DFM and moldflow analysis from suppliers.

- Start with pilot runs before large-scale production.

- Audit facilities or conduct virtual inspections of mold and QC areas.

- Ask for quality documents (ISO, FAI, SPC).

- Confirm export packaging and compliance—wood packaging certificates, fumigation, incoterms.

- Negotiate volume and pricing agreements.

- Assess supplier’s resilience, mold storage, raw material backup.

- Ensure continued post-production support—spare parts, tooling maintenance.

Industry adoption of ISO 9001:2015 facilitates seamless quality synchronization across global suppliers .

Sustainability and the Future of Plastics

- Strong push for post-consumer resin (PCR) and bio-based alternatives.

- Increasing investment in end-of-life recycling systems by resin giants.

- Lightweight designs reduce carbon footprint—smithing tools with recycled plastic variants.

- EU REC Directive and US EPA pushing bio-content mandates by 2028.

- Tech-forward plants using renewables and circular manufacturing.

Dow, SABIC, and ExxonMobil report active eco-resin development and closed-loop pilot projects.

FAQs

-

Can resin giants produce finished parts?

No–they sell resin only; all parts are molded by processors or custom molders. -

How fast can molds be delivered?

Fast-turn tooling is 5–7 days in-house; outsourcing doubles lead time. -

What tolerances are possible?

±0.05 mm standard; down to ±0.01 mm with precision tooling and climate control. -

Are high-performance resins available?

Yes, including medical-grade, bio-based, flame-retardant, and PCR materials. -

Can suppliers ship internationally?

Yes—global support with export packaging, logistics, and customs compliance.

Conclusion

Resin powerhouses like Dow, ExxonMobil, and SABIC dominate base materials, but top-tier components emerge from the best molders. In 2025, leaders like Prime Custom Parts, Xometry, ProtoLabs, Fictiv, Protolux, FormFit, TechSource, and ProMold excel with advanced engineering, fast service, sustainability, and global reach.

👉 Connect with Prime Custom Parts today at [email protected] or through their website for expert help and a free quote.