Top 8 Injection Mold Techniques Used in Metal Part Manufacturing Today: What Works Best in 2025?

Manufacturers today face tighter tolerances, shorter lead times, and stricter performance specs. Choosing the right injection molding technique can reduce costs and ensure part consistency.

This guide explores the top 8 injection mold techniques used in metal part manufacturing. From high-pressure die casting to metal injection molding (MIM), we compare each method’s process, pros, and best-use scenarios.

If you’re sourcing high-strength components or building molds for CNC-compatible geometries, understanding your options helps you get it right the first time.

What are the molding techniques used to manufacture a metal-based component?

Modern metal manufacturing involves several precision molding methods.

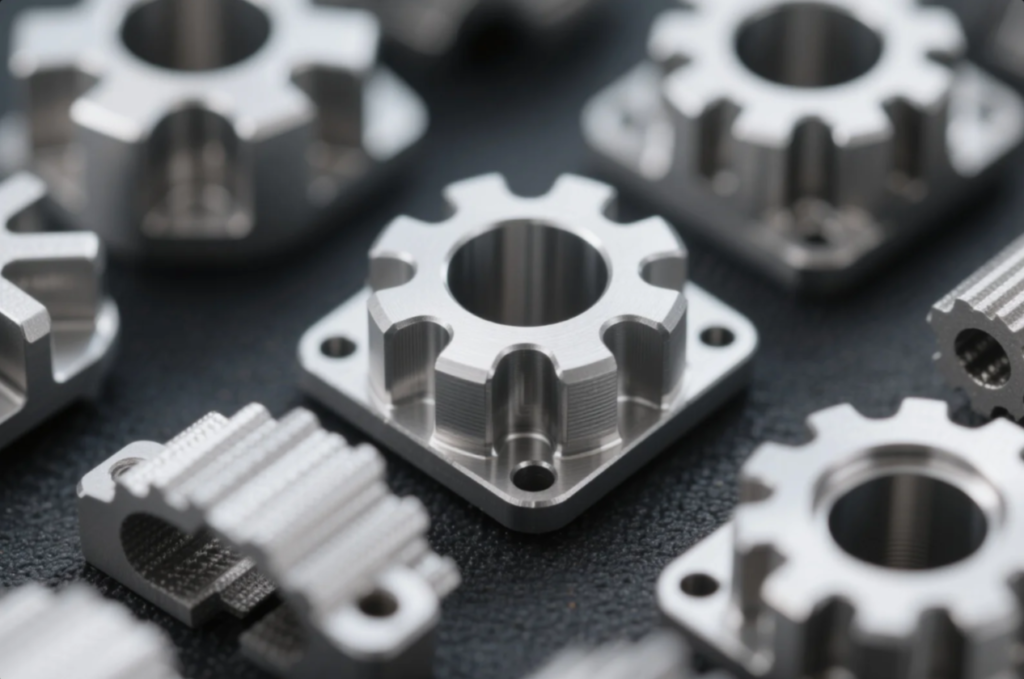

The most common techniques for producing metal parts via molding include Metal Injection Molding (MIM), die casting, centrifugal casting, investment casting, and insert molding.

Comparison of Metal Molding Methods

| Technique | Material State | Main Benefit | Ideal Applications |

|---|---|---|---|

| MIM | Fine powder | High precision, fine detail | Medical, aerospace, gears |

| Die Casting | Molten | High-speed production | Automotive, electronics |

| Investment Casting | Molten | Complex internal geometry | Valves, pumps, blades |

| Centrifugal Casting | Molten | High integrity cylinders | Pipes, rings, bushings |

| Insert Molding | Hybrid | Metal + plastic in one step | Connectors, handles, tool housings |

Prime supports global buyers with all major mold types, helping optimize tooling for product goals and batch size.

Which metal casting process is most like injection molding?

For high-volume runs with repeatable accuracy, one method stands out.

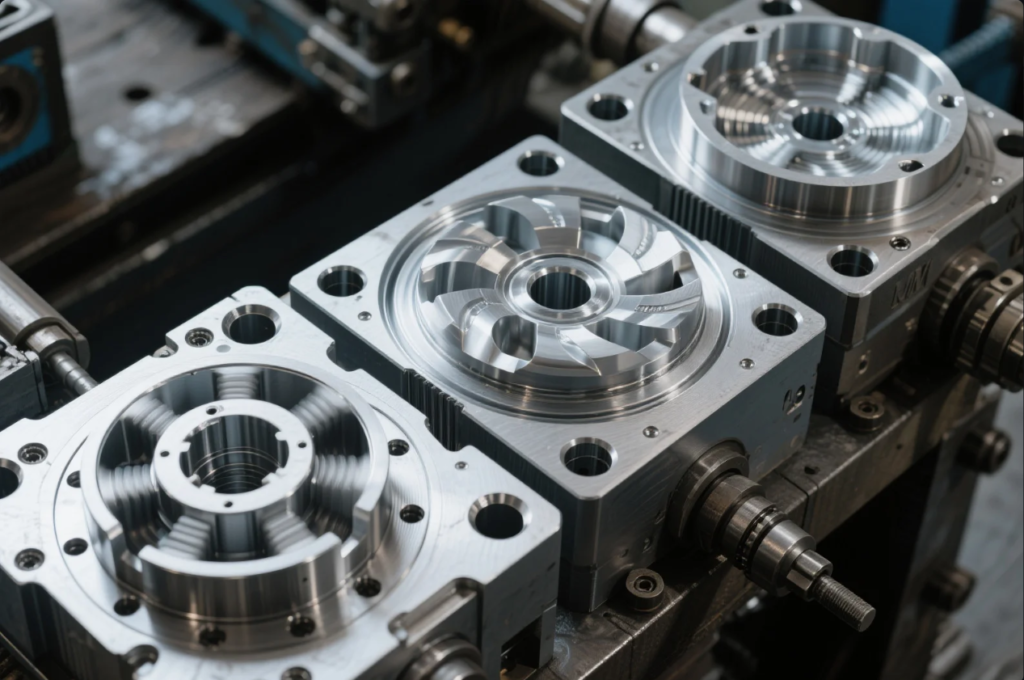

Die casting is most similar to plastic injection molding, as both processes use permanent molds, high pressure, and fast cycle times.

Injection Molding vs. Die Casting

| Feature | Die Casting | Injection Molding |

|---|---|---|

| Material | Molten metal (Al, Zn) | Thermoplastics/resins |

| Tooling | Steel mold (H13, P20) | Steel or aluminum mold |

| Pressure Range | 10,000–30,000 psi | 10,000–20,000 psi |

| Cooling Time | Longer (high temp) | Shorter (plastic flow) |

Learn more from Dynacast’s technical library.

At Prime, we build custom die casting molds with in-house H13 tooling and support both high-pressure and low-pressure aluminum/zinc processes.

What are the methods of injection molding?

Not all molds are made the same. Choosing the right method can simplify tooling and reduce part cost.

Common injection molding methods include standard injection molding, overmolding, gas-assisted molding, insert molding, and micro-injection molding.

When to Use Which Injection Method

| Method | Description | Best For |

|---|---|---|

| Standard Molding | Single-shot fill into steel mold | High-volume, general parts |

| Overmolding | Layers a second material over core | Grips, soft-touch, dual-color |

| Gas-Assisted Molding | Gas forms hollow features inside mold | Handles, frames, large covers |

| Insert Molding | Inserts metal part before injection | Connectors, bushings, switches |

| Micro Molding | Micron-scale part production | Sensors, medical implants |

Prime provides hybrid molding solutions with multi-material injection, custom insert fixtures, and precision cavity design for small-run and high-volume production.

Can injection molding be used for metals?

Absolutely. Metal injection molding has changed the game for high-precision, low-cost metal part production.

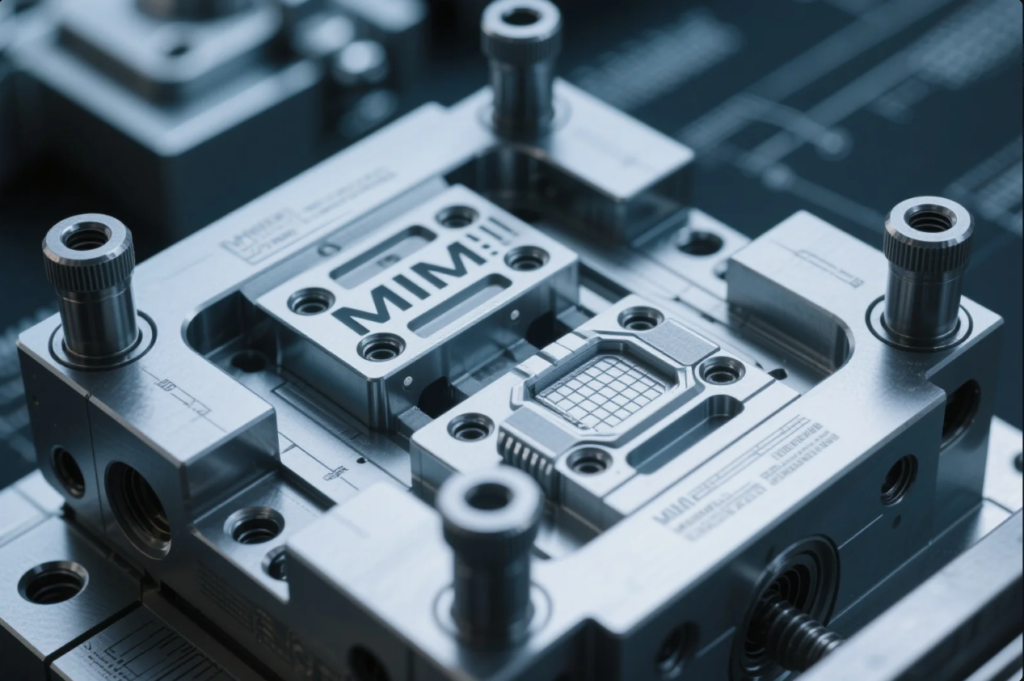

Metal Injection Molding (MIM) uses fine metal powder mixed with a binder to form a plastic-like feedstock. This material is injection molded, debound, and sintered to form solid metal parts.

Why MIM Works for Metal Components

| Advantage | Description |

|---|---|

| Small Part Precision | Tolerances as fine as ±0.01 mm |

| Complex Shapes | Internal holes, threads, logos |

| High Strength | Comparable to machined metal |

| Batch Scalability | Suitable for 1,000–1,000,000 parts/year |

Prime delivers MIM molds, debinding fixtures, and post-sintering CNC operations under strict quality standards. Our MIM customers include buyers in the medical, automotive, and aerospace sectors.

FAQs

Q1: Is MIM cheaper than CNC machining?

A1: Yes—for small, complex parts. After tooling, per-part costs are lower than CNC.

Q2: What metals are used in injection molding?

A2: Stainless steel (316L, 17-4PH), titanium, copper, tungsten, and more.

Q3: What is the minimum batch for MIM?

A3: Generally 1,000 pieces. Prime supports trial runs as low as 200 pcs with shared tooling.

Q4: Is die casting better than MIM?

A4: For large parts or low-complexity shapes, yes. For fine details and hardness, MIM wins.

Q5: Can you mold threaded holes?

A5: Yes. Both MIM and insert molding support internal and external threads.

Contact Information

Need help selecting the right injection mold process?

- 🌐 Website: https://primecustomparts.com

- 📧 Email: [email protected]

We offer:

- Mold design and material consulting

- Tooling for die cast, MIM, and insert molding

- Short-run and mass production options

- ISO-certified QA and international shipping

Get the right mold. Choose the right process. Build with Prime.

Whether you’re building for automotive, aerospace, or precision electronics—our team delivers global injection mold support with fast lead times and consistent quality.