Top Custom Forged Parts Suppliers for Automotive and Aerospace Industries

Which is the world’s largest forging company?

Bharat Forge, headquartered in Pune, India, is the globe’s largest forging enterprise. Established in 1961, the company has 14 plants worldwide and over 17,000 employees. In 2024, Bharat Forge generated roughly \$1.5 billion in revenue. The company supplies automotive crankshafts, aerospace discs, industrial shafts, and more. It operates high-capacity presses up to 12,000 kN, top-tier CNC machining, ring rolling mills, metallurgical labs, and NDT facilities. Bharat Forge holds major certifications including ISO 9001, IATF 16949, and NADCAP ([linkedin.com][1], [marketresearch.com][2], [precedenceresearch.com][3]).

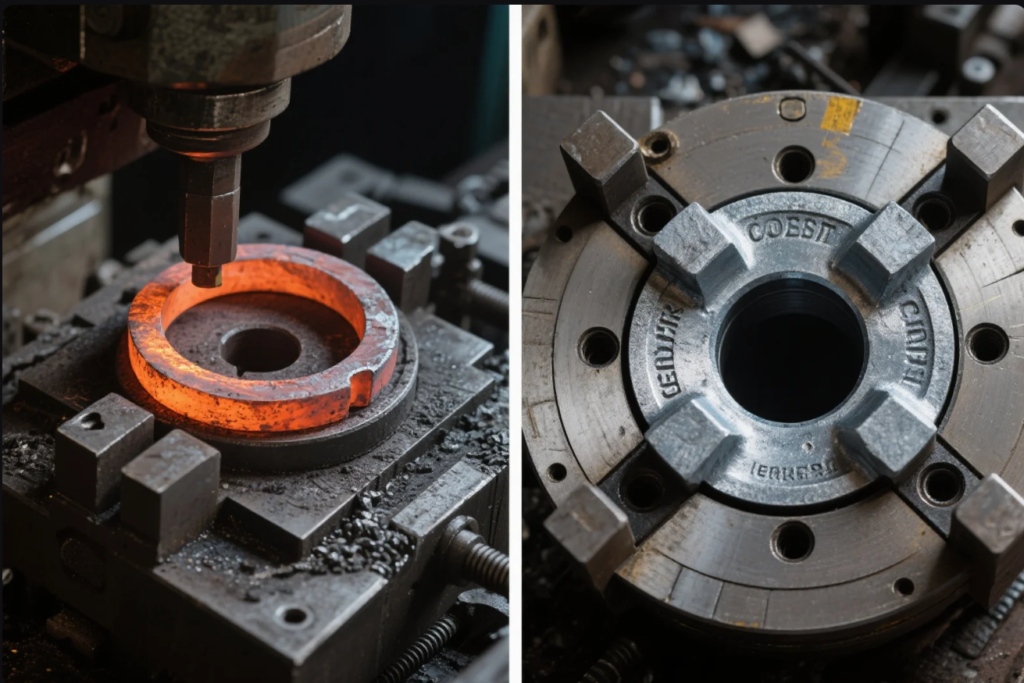

What are the 4 types of forging?

Forging uses different methods depending on the part design, material, and required precision:

- Open‑Die Forging – Used for large shafts & billets; typical tolerance ±0.5 mm.

- Closed‑Die Forging – Best for high volume gears & hubs; tolerance ±0.1 mm.

- Rolled‑Ring Forging – Ideal for rings and flanges; tolerance ±0.3 mm.

- Press/Precision Forging – High-precision parts like aerospace components; tolerance ±0.05 mm.

These definitions align with standard industry practice ([en.wikipedia.org][4], [en.wikipedia.org][5], [thebusinessresearchcompany.com][6], [globalgrowthinsights.com][7]).

What is aerospace forging?

Aerospace forging involves creating components that meet stringent quality, traceability, and performance standards. Typically made from high-performance alloys like Ti-6Al-4V, Inconel, or aluminum 7075, aerospace forgings include turbine discs, rotor shafts, landing gear parts, and structural fittings. They demand processes like closed-die and press forging under NADCAP approval, guaranteeing consistency and fatigue resistance ([ajaxerie.com][8]).

Suppliers such as Farinia Group and Kobe Steel specialize in aerospace-grade forging, backed by rigorous quality management and precision manufacturing.

What is custom forging?

Custom forging covers end-to-end services: customer-designed parts tailored to precise specs. This includes DFM review, CAD simulation, alloy sourcing, and die design. It often incorporates services like trimming, heat treatment, CNC machining, coating, and traceability. Companies such as Shandong Prime International provide complete turnkey solutions for automotive and aviation markets.

Custom forging ensures high margins by reducing scrap, shortening lead times, and delivering precise parts without over-engineering the process.

Top Custom Forged Part Suppliers for Automotive & Aerospace

1. Bharat Forge (India)

World leader with global reach, NADCAP certification, and mega-press capabilities.

2. Thyssenkrupp Forging (Germany)

Specializes in industry‑4.0 forging, smart press automation, and aerospace-grade tools.

3. Scot Forge (USA)

High-precision aerospace forgings with in-house machining, alloy expertise, and NADCAP compliance.

4. Kobe Steel (Japan)

Precision forging of titanium and nickel alloys for aircraft and industrial applications.

5. Farinia Group (France)

Aerospace-grade precision forging with IIoT control and digital twin integration.

6. Shandong Prime International (China)

ISO‑certified turnkey forging with low MOQ, rapid delivery, and global shipping.

Industry Marketplace & Market Size Insights

The global forging market size is projected to grow rapidly:

- USD 86.3 billion in 2024, rising to USD 90.9 billion in 2025, and expected to reach USD 137.4 billion by 2033 at CAGR 5.3% ([arxiv.org][9], [globalgrowthinsights.com][7]).

- Another source reports growth from \~USD 93.9 billion in 2024 to USD 147.3 billion by 2033 at 5.2% CAGR ([businessresearchinsights.com][10]).

- A third forecast shows growth from USD 102.3 billion in 2025 to USD 199.7 billion by 2034 at 7.7% CAGR .

Aerospace Forging Segment:

- Valued at \~USD 33.7 billion in 2024, expected to rise to USD 36.3 billion in 2025, reaching USD 49.7 billion by 2029 (8.1% CAGR) .

- U.S. led the aerospace forging market with \~32% share (\~USD 10.8 billion) ([globenewswire.com][11]).

Key Demand Drivers:

- Electric vehicle drivetrains (automotive forging \~45% share)

- Aircraft engine and structural parts (aerospace growth \~8%+ CAGR)

- Heavy machinery and energy sector

Asia-Pacific dominates with \~50% market share, North America \~20–25%, and Europe \~20% ([globalgrowthinsights.com][7], [thebusinessresearchcompany.com][6]).

Emerging Trends & Technology Adoption

Digital & AI Enhancements:

- Integration of IIoT sensors plus MES delivers real-time monitoring and predictive maintenance (+30% yield) ([globalgrowthinsights.com][7]).

- Digital twin platforms—e.g. DeepForge research—provide microstructure optimization via AI ([arxiv.org][12]).

Industry 4.0 & Robotics:

- Robotic press handling, flash trimming, and defect detection reduce scrap and labor, as seen in LinkedIn’s coverage of North American facilities .

Advanced Materials:

- Titanium, aluminum, and superalloy forging is on the rise—especially for EV, aerospace, and industrial applications.

Green Manufacturing:

- Induction heating, solar frameworks, and scrap loops are cutting energy use by \~20–30% .

- Accountability to climate targets inspires eco-friendly practices across forging operations.

Hybrid & Near-Net Forming:

- Forging + CNC/3D printing combos reduce post-machining; research into flashless forging (IPH Hannover) is ongoing ([en.wikipedia.org][5]).

Supplier Selection Checklist

| Focus Point | Evaluation Guidance |

|---|---|

| Certification | Check for ISO, IATF, NADCAP approval |

| Forging Technology | Confirm press capacities and finishing |

| Alloy Handling | Ensure capability with relevant aerospace/auto alloys |

| Tolerance & Precision | ±0.05 mm for aerospace, ±0.1 mm for powertrain |

| Digital / Data Access | Real-time dashboards, traceability logs |

| Customization Services | CAD optimization, tooling, heat treatment |

| ESG Practices | Induction heating, recycling, energy benchmarks |

| Logistics & Delivery | Confirm export compliance, scheduling, tracking |

Conclusion & Call to Action

Custom forging is vital to chest high-performance automotive and aerospace components—where safety, weight, and precision matter most. The top suppliers identified here excel in scale, innovation, and compliance. Shandong Prime International offers a compelling turnkey solution: precision forging, low MOQ, rapid delivery, and global service.

📧 Email Shandong Prime International for a quote or CAD review: [email protected]

🌐 Visit: https://primecustomparts.com

Get your free technical consultation today—ensure your next project meets industry-leading standards with cost efficiency and global delivery support.