Top Custom Metal Mold Solutions for Medical Device Production in 2025?

Medical device makers face strict precision, cleanliness, and regulatory pressure. Poor mold quality risks compliance and patient safety.

Custom metal molds are vital for high-precision, certified medical components. In 2025, accuracy and cleanliness are non-negotiable.

Let’s explore top materials, mold maker demand, manufacturing definitions, and the role of molds in medical device production.

What is the most suitable metal for the medical device?

Choosing the right metal is critical in the medical industry. It must be biocompatible, corrosion-resistant, and high-strength.

Stainless steel (316L), titanium, and aluminum are the most suitable for medical device molds and parts.

Comparison of Medical Metals

| Metal | Key Properties | Common Applications |

|---|---|---|

| 316L Stainless | Biocompatible, corrosion-resistant | Surgical instruments, implant tools |

| Titanium | Light, strong, bioinert | Bone plates, implant prototypes |

| Aluminum | Lightweight, heat conductive | Enclosures, handheld device casings |

| Cobalt-Chromium | High wear, implantable | Knee/hip joints, dental parts |

At Prime, we produce ISO 13485-ready CNC molds for plastic housings and aluminum compression molds for diagnostic tools. For long-life surgical molds, we recommend hardened H13 steel inserts.

Learn more at FDA’s Medical Device Materials Guide.

Are mold makers in demand?

Skilled mold makers are more important than ever, especially in regulated industries like medical.

The global demand for precision mold makers continues to grow, fueled by healthcare, aerospace, and electronics.

Why Mold Makers Matter in 2025

| Reason | Impact on Production |

|---|---|

| Rising regulatory requirements | Tight tolerances, validated tools |

| Increase in device miniaturization | Micro molds, microfluidic channels |

| Shorter product cycles | Faster mold changes and revisions |

| Shift toward cleanroom molding | Mold finish must meet Class 100k+ spec |

Reports from U.S. Bureau of Labor Statistics show steady demand for mold/toolmakers. At Prime, our toolroom supports multi-cavity medical molds, used by clients in the US, Germany, and the Middle East.

We also help clients navigate mold validation steps like IQ/OQ/PQ under ISO 13485 frameworks.

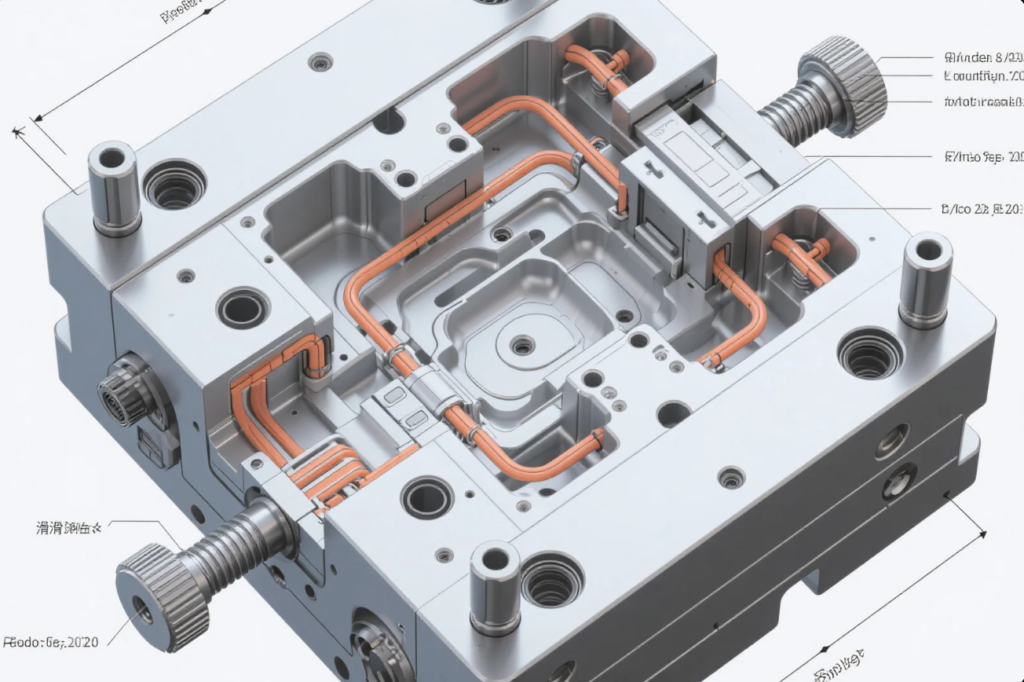

What is a mold in manufacturing?

Many confuse the term “mold” with casting or general shaping.

In manufacturing, a mold is a hollow form used to shape material into a precise structure—most often plastic or metal parts.

What Makes Medical Molds Unique?

| Feature | Medical Mold Requirement |

|---|---|

| Material | Must resist wear and sterilization chemicals |

| Surface Finish | Needs to meet optical-grade or Class A polish |

| Precision | Often ±0.01 mm or tighter |

| Cleanability | Mold must resist bacterial adhesion |

In 2025, most medical device manufacturers use high-cavitation injection molds built with hardened tool steel, laser-polished to avoid contamination zones. At Prime, we deliver molds suitable for ultrasonic cleaning and EO sterilization.

Want to dive deeper? Check out Plastics Technology’s Guide to Injection Molding.

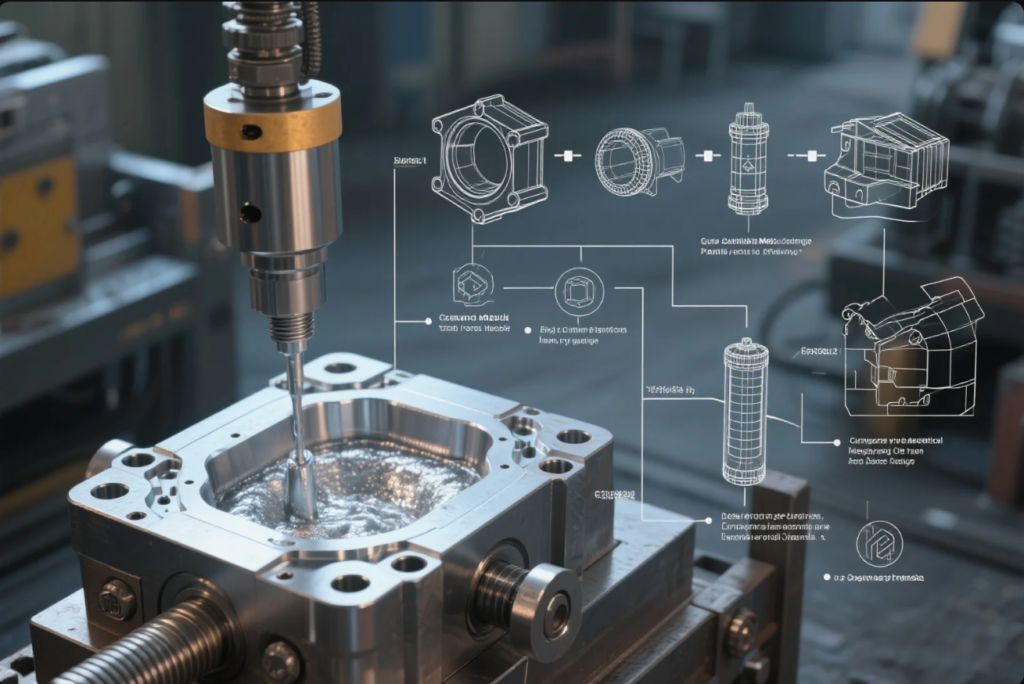

What is mold in metal casting?

Not all molds are injection-based. Metal casting uses heat and gravity or pressure to form components.

In metal casting, a mold is a cavity used to pour molten metal into a specific shape.

Common Medical Casting Use Cases

| Process | Used For |

|---|---|

| Investment Casting | Surgical scissors, orthopedic tools |

| Die Casting | Device casings, power unit brackets |

| CNC Cast/Machined | Custom R\&D lab parts, dental jigs |

Our customers use custom casting molds to produce housings for imaging equipment and aluminum die-cast control units. When finish and strength matter, we often combine casting with CNC to meet both form and function.

Explore further at Wikipedia – Metal Casting.

FAQs

1. What mold types are best for medical devices?

Injection molds with hardened inserts are best for plastic parts. Investment molds suit stainless surgical tools.

2. Can Prime provide FDA-compliant mold documentation?

Yes. We offer mold drawings, material certifications, IQ/OQ checklists, and validation reports.

3. What’s your cleanroom compatibility?

Our molds support Class 100k to Class 10k cleanroom operations. Finish can be optical-grade on request.

4. How many shots does a medical mold last?

H13 steel inserts can exceed 500,000 shots under proper maintenance. We offer mold life tracking charts.

5. Can I request a prototype before full tooling?

Yes. We offer CNC aluminum test molds within 7–10 days to validate part geometry.

Conclusion

Medical molding demands precision, hygiene, and trust. Prime delivers it all—through certified metal mold solutions.

Partner with Prime, your ISO-ready mold supplier for medical device production in 2025 and beyond.

📞 Email: [email protected]

🌐 Website: https://primecustomparts.com

Let’s build medical-grade confidence—mold by mold.