Top Custom Plastic Parts Suppliers for Industrial Applications: A Comprehensive Guide?

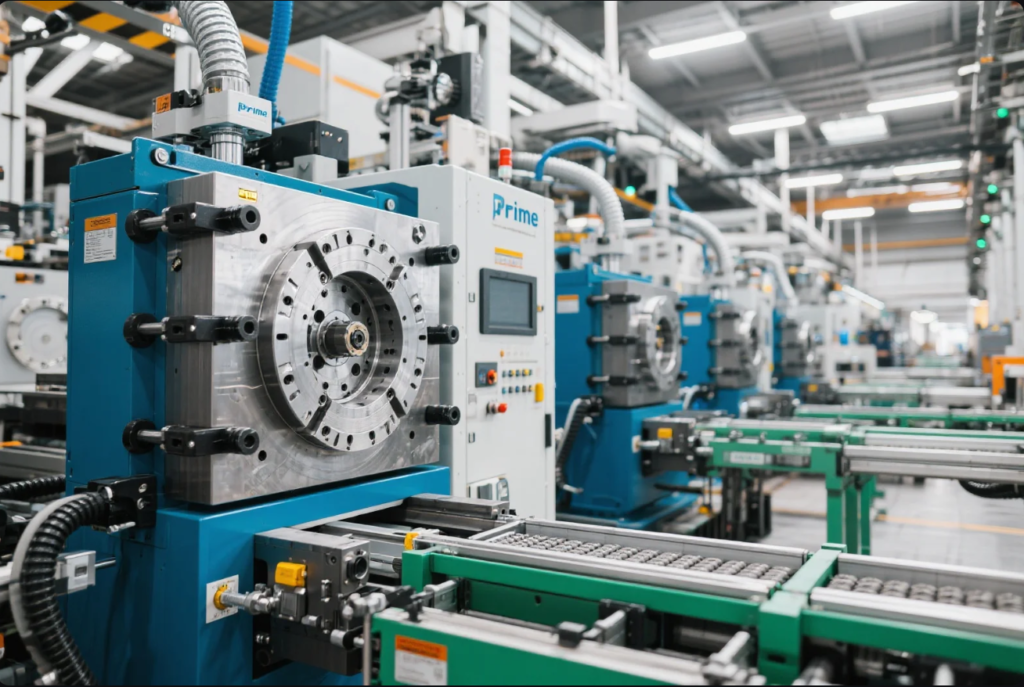

Every industrial project demands plastic parts that are accurate, durable, and delivered fast. Choosing the right supplier is critical to ensuring project success, minimizing costs, and maintaining production schedules. This guide will help you identify the world’s top plastic suppliers, understand the manufacturing process, and navigate custom sourcing.

Who is the biggest manufacturer of plastic?

Global resin leaders set the foundation for plastic manufacturing. Their output volume impacts global pricing and availability.

The top three resin manufacturers globally include:

These corporations produce tens of millions of metric tons of plastic annually. However, they mainly supply raw materials to processors and converters. For companies seeking finished, custom injection-molded components, smaller specialized firms like Prime Custom Parts offer far more agility and personalized service.

Which company is best for plastic?

The best plastic supplier is not just about size or reputation—it’s about consistent quality, speed, flexibility, and service.

Key traits of an ideal plastic parts supplier:

- ISO Certification (e.g., ISO 9001 for quality systems)

- Full in-house mold-making

- Diverse plastic material support (ABS, PP, PC, POM, PA, TPU, PET)

- Fast lead time (7–15 days for most orders)

- Strict quality control (SPC, CMM)

- Professional engineering support

Prime Custom Parts meets all the above standards, with over 20 years of experience exporting to North America, Europe, and the Middle East.

How do you get a plastic part manufactured?

Here’s a simplified workflow:

- Submit your CAD files – Preferably in STEP or IGES format.

- Receive a DFM report – Manufacturers analyze the design for manufacturability.

- Select resin materials – Based on mechanical and environmental needs.

- Tooling/mold production – Usually aluminum or steel molds.

- T1 sampling and approval – First article inspection and revisions.

- Mass production – After confirmation, production begins.

- QC and packing – Visual, dimension, and mechanical checks.

- Delivery – Via air, sea, or express based on urgency.

A good supplier like Prime will walk you through each phase and offer transparent communication throughout.

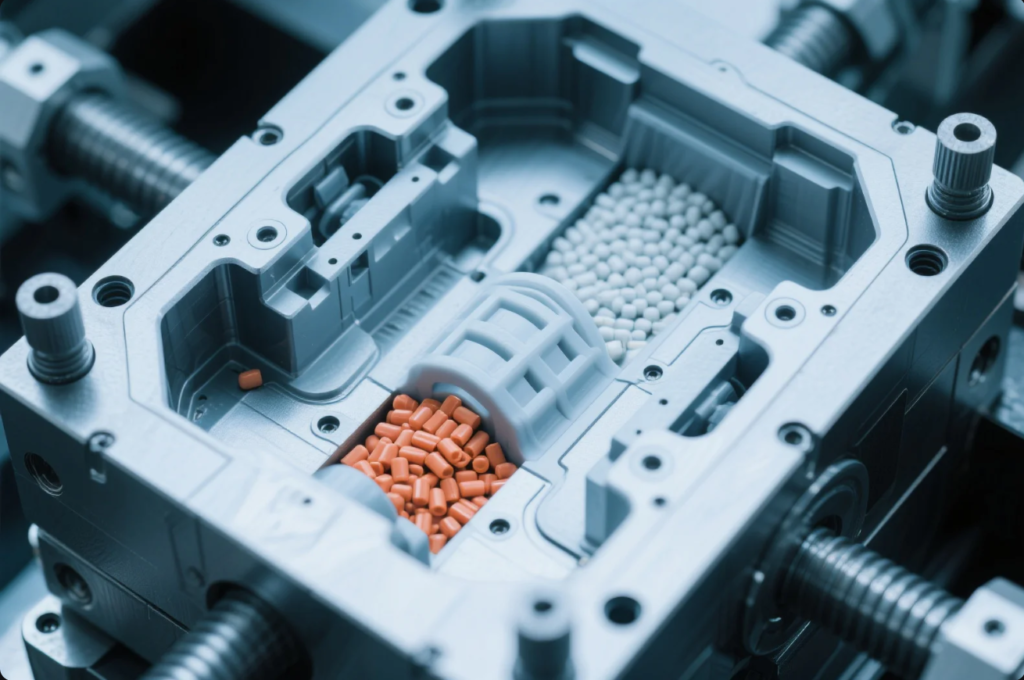

What is the plastic injection molding process?

Plastic injection molding involves:

- Clamping: Mold halves are locked in position.

- Injection: Molten plastic is injected into the mold cavity.

- Dwelling: Pressure holds the plastic to ensure cavity fill.

- Cooling: Resin solidifies while inside the mold.

- Ejection: Part is pushed out after mold opens.

This process is widely used because it:

- Produces parts with high repeatability

- Supports tight tolerances (±0.05mm typical)

- Handles complex geometries

- Enables overmolding and insert molding

For more detail, see Protolabs’ Guide to Injection Molding.

What industries rely on custom plastic parts?

Plastic parts are essential across industries:

| Industry | Common Plastic Parts Used |

|---|---|

| Automotive | Clips, fasteners, housings, fluid reservoirs |

| Medical | Diagnostic housings, test kits, enclosures |

| Consumer Goods | Appliance parts, handles, packaging components |

| Electronics | Connectors, casings, insulators |

| Agriculture | Sprayers, pumps, seed bins |

| Construction | Spacers, anchors, pipes |

Prime Custom Parts has served all of the above markets, with expertise in both commodity and engineering-grade materials.

What makes a good custom plastic supplier?

Not all suppliers are created equal. Consider these selection criteria:

- In-house Tooling – Reduces lead time and cost.

- Material Range – Should include commodity (PP, PE) and engineering (PA, POM) plastics.

- Certifications – ISO 9001, RoHS, REACH, UL where required.

- Global Export Experience – Ensures proper packaging, documentation, and shipping.

- Engineering Team – Offers feedback and design improvements.

Suppliers like Prime Custom Parts are built for industrial clients who need reliability, precision, and responsiveness.

FAQs

Q1: What’s your typical production lead time?

For most molds, 7 days. For mass production, 10–15 days after approval.

Q2: What tolerances can be held?

±0.05mm for most applications. Tighter tolerances upon request.

Q3: Can you do insert molding?

Yes, including brass inserts, magnets, threaded fasteners.

Q4: What plastic grades do you support?

More than 15 resins including PC+ABS, Nylon 66, TPE, HDPE, and flame-retardant grades.

Q5: Do you support eco-friendly plastics?

Yes. We offer bio-based, recyclable, and food-safe options. Contact us for specifics.

Q6: How can I get a quote?

Visit primecustomparts.com or email [email protected].

Conclusion

Choosing the right plastic part supplier makes all the difference. Industrial clients need partners who are certified, responsive, and technically capable.

Prime Custom Parts offers all of the above—with proven export experience, rapid prototyping, and full-scale production.

📩 Contact us today for a free quote at [email protected] or visit primecustomparts.com