Top Global Forging Companies Specializing in Custom Metal Components?

Which is the World’s Largest Forging Company?

Bharat Forge is currently the world’s largest forging company, based in Pune, India. It leads in size, global presence, and technical capabilities.

Highlights:

- Revenue: Over \$1.5 billion

- Facilities: 14 across India, USA, UK, Germany

- Industries Served: Automotive, Aerospace, Oil & Gas, Defense

- Certifications: ISO 9001, IATF 16949, NADCAP

Their focus on R\&D, high-tonnage presses, and global logistics makes them a top choice for large-volume and mission-critical parts.

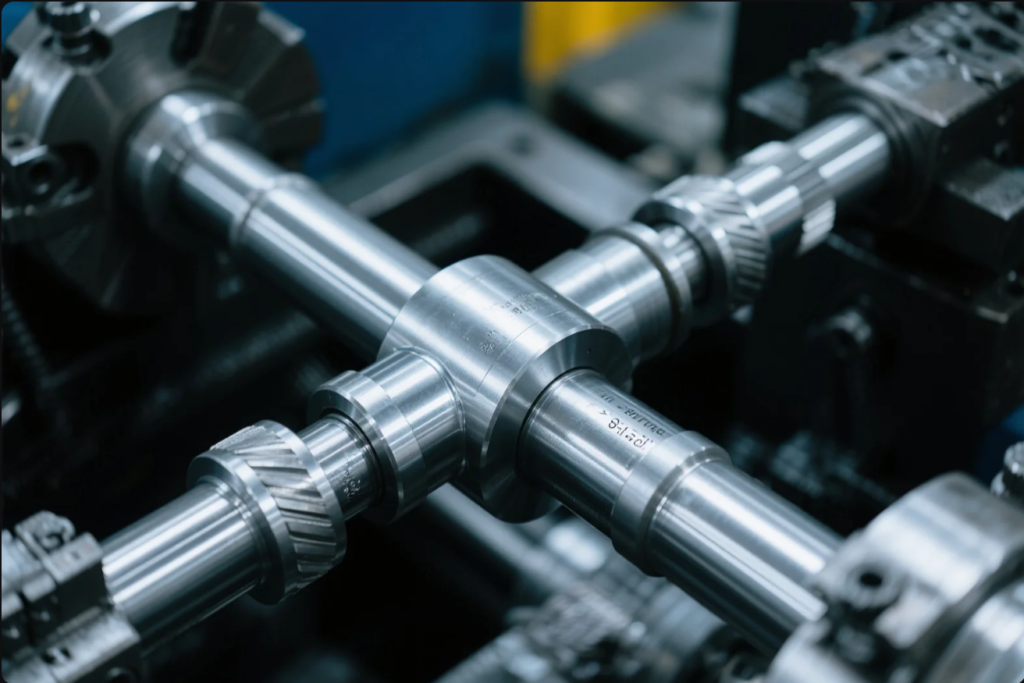

What Are the 4 Types of Forging?

Forging methods vary by size, precision, and cost. Here’s how to choose:

1. Open-Die Forging

- Tolerance: ±0.5 mm

- Ideal for large shafts, blocks

- Flexible and low tooling costs

- Suited for energy and heavy machinery

2. Closed-Die Forging

- Tolerance: ±0.1 mm

- Suitable for gears, brackets, couplers

- High volume and consistent shape

- Used in automotive and general machinery

3. Rolled-Ring Forging

- Tolerance: ±0.3 mm

- For bearings, turbine rings, flanges

- Strong grain alignment

- Common in aerospace and energy sectors

4. Press Forging

- Tolerance: ±0.05 mm

- Uses hydraulic/mechanical presses

- High precision for engine, aerospace parts

- Most suitable for tight-tolerance parts

| Type | Applications | Tolerance | Tooling Cost |

|---|---|---|---|

| Open-Die | Shafts, blocks | ±0.5 mm | Low |

| Closed-Die | Gears, levers | ±0.1 mm | High |

| Rolled-Ring | Bearings, flanges | ±0.3 mm | Medium |

| Press Forging | Aerospace, EV parts | ±0.05 mm | High |

How Big is the Global Forging Market?

As of 2024, the global forging market was valued at \$80 billion and is expected to reach \$105 billion by 2030, according to Grand View Research.

Major Drivers:

- EV component demand

- Aerospace reindustrialization

- High-strength steel for renewable energy

- Precision parts for medical and military sectors

Regional Shares:

- Asia-Pacific: 40% (China, India)

- North America: 25% (US, Canada)

- Europe: 20% (Germany, France)

- ROW: 15% (Middle East, LATAM)

China and India remain global leaders in volume. However, Europe and North America focus on quality-critical industries like defense and aerospace.

What is the Future of Forging?

Forging is evolving into a smarter and more sustainable industry driven by four core trends:

1. Automation

Modern forging lines use robots, automatic trimmers, and force-correcting presses.

Example: Thyssenkrupp Forging Group implements smart press technology to optimize gear forging with real-time pressure control.

2. Digitalization

IIoT systems track force, temperature, die condition, and production metrics:

- Real-time dashboards

- Traceability logs

- Predictive maintenance

- Digital twin simulations

Farinia Group uses data analytics for process stability and zero-defect forging.

3. Lightweight Materials

High-strength and corrosion-resistant alloys are rising:

- Ti-6Al-4V Titanium for aircraft

- 6061/7075 Aluminum for EVs

- Duplex Stainless Steel for subsea and valves

These require special dies and strict temperature control.

4. Sustainability

Forging shops now focus on eco-friendly solutions:

- Induction heating saves 20–30% energy

- On-site scrap recycling

- Solar power and carbon offsetting programs

As Forbes reports, smart plants reduce waste by 20% and increase uptime by 15%.

Conclusion & Next Steps

The future of forging depends on adaptability, precision, and reliability. For B2B buyers, especially in automotive, energy, and aerospace sectors, supplier selection now involves more than cost.

Selection Checklist:

✅ Confirm forging method matches design

✅ Demand ISO, IATF, NADCAP certifications

✅ Ensure automated lines and digital quality controls

✅ Assess sustainability capabilities

✅ Validate export experience and delivery timelines

Why Choose Prime?

Shandong Prime International is a leading manufacturer in custom metal components, serving B2B clients worldwide since 1993.

Key Offerings:

- CNC Parts, Forged Parts, Stamping Parts

- Plastic and Fastener Assemblies

- Customized Packaging & Labels

- ISO 9001, RoHS Certified

- 10 production lines for short lead times

- Global shipping & English-speaking support

📧 Contact us: [email protected]

🌐 Visit: https://primecustomparts.com

✅ Get a Free Quote

✅ Upload your drawings

✅ Receive expert alloy advice

✅ Request packaging samples

Let Prime help you reduce costs, improve delivery reliability, and grow your industrial supply chain.