Top Industrial Applications of Metal Parts in Automotive and Aerospace 2025?

As automotive and aerospace industries advance toward electric vehicles, unmanned aircraft, and supersonic travel, demand for high-precision, lightweight, and durable metal parts has surged. In 2025, these parts are essential for performance, safety, and innovation.

This guide covers:

- What metals are used in aerospace and automotive

- Key applications across both industries

- Why custom machining is essential

- How Prime supports critical production needs

I’ll share technical insights, real use cases, and actionable takeaways for engineers and procurement managers evaluating suppliers.

1. What Metals Are Used in the Aerospace Industry?

Aerospace thrives on materials that offer superior stiffness, high-temperature strength, and corrosion resistance under extreme conditions. Let’s examine:

1.1 Titanium (e.g., 6Al-4V)

- Properties: Excellent strength-to-weight (< 4.5 g/cm³), corrosion-resistant, biocompatible

- Uses: Engine blades, airframe elements, landing gear pivots

1.2 Aluminum Alloys (e.g., 2024, 6061, 7075)

- 2024: strong, good fatigue resistance;

- 6061: weldable, machinable;

- 7075: high strength, used in aircraft structure

1.3 Nickel-based Superalloys (e.g. Inconel 718)

- Maintain strength at >700 °C

- Used for turbine discs, combustion chambers, exhaust systems

1.4 Stainless & Specialty Steels (e.g. 17-4PH, 15-5PH)

- Provide fatigue strength and dimensional precision

- Used in fasteners, shafts, sequence disc assemblies

Why These Metals?

- They comply with standards: AS9100, ISO 9001, AMS…

- NASA and SAE outline material Grades: NASA materials and SAE Standards

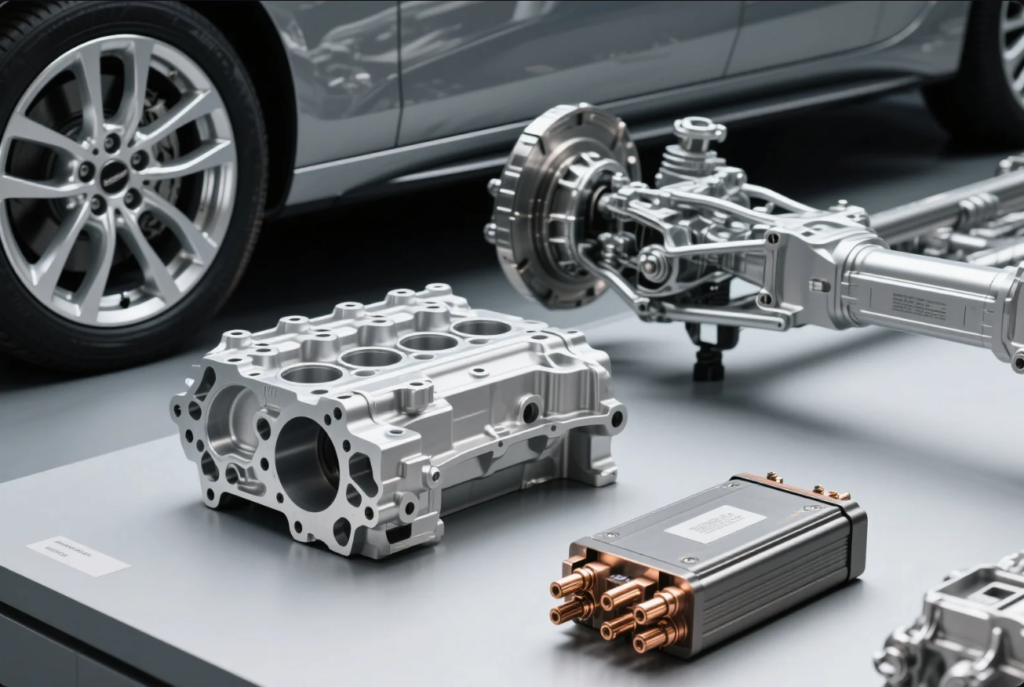

2. What Metals Are Used in the Automobile Industry?

Automotive is fueling innovation through lightweighting, electrification, and increased crash performance. Materials play a key role:

2.1 High-Strength / Advanced High-Strength Steel (AHSS)

- Yields 450–1500 MPa;

- Critical for structural brackets, safety cell, chassis cross-members

2.2 Aluminum Alloys (6XXX & 7XXX series)

- Used in engine compartments, EV housings, body panels

- Offers lightness and cost efficiency

2.3 Magnesium Alloys

- About one third the density of aluminum

- Ideal for housings, structural brackets

2.4 Copper & Copper Alloys

- Key for EV motors, wiring harnesses, thermal management systems

Trends:

- EV platforms boost usage of thermal copper parts

- Body structure transitions to hybrid aluminum-steel construction

Sources overview: WorldAutoSteel & AutomotiveWorld

3. What Is Steel Used for in Aerospace?

Though lighter metals dominate primary structures, the aerospace industry relies on steel for strength and precision in key systems:

3.1 Landing Gear

- Steel 300M, 4340M

- High resistance to tensile stress, load cycles, impact

3.2 Actuator Shafts & Valve Pins

- Made from 17‑4PH, 15‑5PH stainless

- Excellent fatigue resistance

3.3 Fasteners, Brackets, Interfaces

- Stainless or alloy steel with surface, process certifications

- Critical in cabin doors, safety systems, control linkages

3.4 Steel Tolerates

- Temperature up to 600 °C;

- Surface hardness and finish to microns

Refer to material references at ASM Aerospace Spec Metals & AircraftMaterials

4. What Are the Applications of Metal Parts Across Industries?

Metal parts drive critical industries thanks to their mechanical, thermal, and electrical properties.

4.1 Aerospace

- Engine and structural components, actuators, landing gear, fasteners

4.2 Automotive

- Crash structures, housings, wheel hubs, suspension subframes

4.3 Medical

- Surgical tools, implants (Ti/SS), sterilizable housings

4.4 Energy

- Heat exchangers, wind turbine brackets, steam turbine rotors, battery modules

4.5 Electronics & Telecom

- EMI shielding, housing, connectors

4.6 Industrial & Infrastructure

- Valves, hydraulic components, custom fittings

These parts leverage CNC machining, casting, stamping, or welding, designed for volume, cost, or complexity requirements.

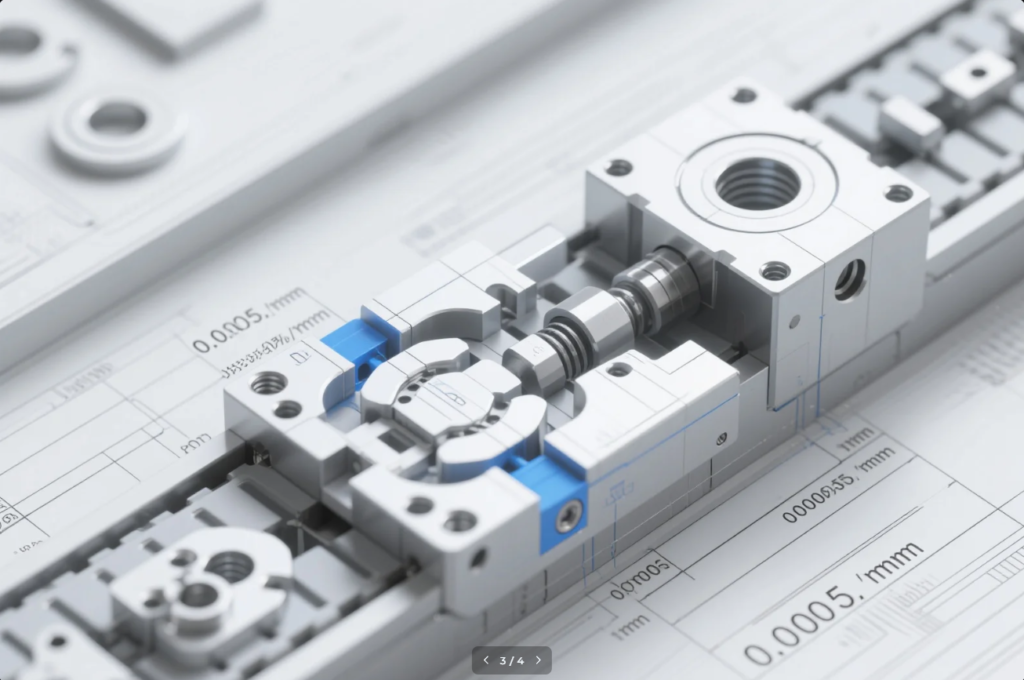

5. Benefits of Custom Metal Parts in Critical Sectors

Off-the-shelf parts can’t meet the tolerance and performance demands of aerospace and new-gen automotive systems.

Key Advantages:

-

Precision & Consistency

- Guaranteed to ±0.005 mm

-

Design Flexibility

- Optimized geometry, weight reduction, heat control

-

Material Traceability

- Full certification from steel mill to CNC part

-

Durability & Lifespan

- Optimized surface coatings, treatments

-

Assembly Simplification

- Fit-first, no rework

-

Service & Maintenance Ready

- Modular inserts ease maintenance

Prime’s clients saved \~45–55% scrap by switching to custom CNC parts over die-cast alternatives.

6. Prime’s Capabilities & Solutions

6.1 Infrastructure

- Ten dedicated CNC and EDM lines

- 200T+ Stamping presses

- Production capacity 10M+ parts/year

6.2 Material Expertise

- Aluminum, Steel, Titanium, Nickel, Copper alloys

- P20, H13, NAK80, 17‑4PH, 7075, 6Al‑4V, Inconel

6.3 Process Capabilities

- CNC 3/4/5-Axis Machining

- Wire / Sinker EDM

- Precision Grinding

- Die Casting & Investment Casting

- Stamping & Automated Welding

- Surface Treatment: Anodizing, Passivation, Cerakote

6.4 Quality Assurance

- ISO 9001 certified

- AS9100, IATF 16949 support

- CMM reports, FAI, PPAP, traceability

6.5 Delivery & Service

- 7‑15 day production lead times

- ISPM-15 export packaging

- After-sales: tool life tracking, inserts & wear maintenance

7. Manufacturing Workflow at Prime

-

Inquiry & Quotation

- Submit CAD, choose materials, propose quantities

-

Design for Manufacturability (DFM)

- Free DFM review, gate, cooling, wall thickness for molds

-

Material Procurement

- Full-traceable certification and lab testing

-

CAM & Simulation

- Moldflow, Moldex3D, NC programming

-

Tooling & Machining

- CNC → EDM → Grinding → Polishing

-

Assembly & Trial Runs

- T0/T1 shots, CMM feedback, optimization

-

Inspection & Documentation

- CMM, FAI reports, steel certificates, packaging

-

Shipping & Lifecycle Support

- ISPM crates, CE/CoC, spare parts, after-sales

8. Quality & Certification Standards

- ISO 9001: Global quality system

- AS9100: Aerospace-specific QA

- IATF 16949: Automotive QMS

- NADCAP: Specialty process accreditation

- ROHS / REACH / CE: Regulatory compliance

- MTR, PMI, FAI, PPAP, CMM Reports

Prime supports OEM documentation including electrostatic sensitive packaging (ESD) and CoC.

9. Case Studies

9.1 Automotive EV Battery Tray

- 7075 aluminum with threaded steel inserts

- ±0.004 mm planar accuracy in 32-seat CNC machining

9.2 Aerospace Engine Bracket

- Titanium 6Al4V

- 5-axis CNC, heat-treated, custom anodizing

9.3 High-Speed Valve Body

- Inconel 718

- Investment casting, 200 µm wall, polishing, NDT inspection

10. Selection & Cost Optimization Guidance

| Part Period | Material | Process | Supplier Tip |

|---|---|---|---|

| Prototype | Aluminum | Machining | Use soft tools for fast delivery |

| Short run | Stainless | CNC | No cast needed, accuracy prime |

| Long run | Titanium/Al-Ni | Casting + finish | Balance cost & complexity |

| Lightweight Needed | Mg alloy | CNC + plating | Safety and handling design important |

For budget planning, use Xometry Mold Cost Estimator

11. FAQs

- What tolerances are possible? ±0.005 mm trackable

- Do you offer first article inspection? Yes; FAI, PPAP included for key industries

- What delivery times? 7‑15 days; expedited options available

- Can you manage complex metal types? Yes; Titanium, Inconel, Mg alloys

- Is custom packaging included? Yes; ISPM-15 safe export crates

12. Conclusion

Custom metal parts define advanced manufacturing in 2025. From EV frames to jet engine components, precision parts ensure innovation, performance, and ROI.

Prime delivers:

- Certified precision machining

- Engineering collaboration and DFM support

- Fast lead times and complete documentation

📞 Email: [email protected]

🌐 Website: https://primecustomparts.com

Let’s build the future together—one precision part at a time.