Top Material Selection Strategies to Reduce Costs in Custom Metal Stamping Parts?

I lose money when parts are overbuilt. You do too. The fix starts with material choices that match real loads, not wishful thinking.

Pick the lowest-cost metal grade that still meets strength, formability, corrosion, and electrical needs. Verify with simple tests and standards. Then lock specs to stop drift and “gold plating.”

I learned this the hard way. I once approved an expensive alloy because a customer’s drawing felt vague. We stamped and plated beautiful parts. They worked, but margins died. I now use a short, disciplined checklist tied to published standards. I pick a metal and finish that hit the numbers with no fat. I update the drawing so later buyers do not drift back to thicker or shinier. If you want a quote with the same discipline, send prints through our Contact page or attach them to an RFQ from our Stamping Parts page so I can respond with data, not guesses.

Comparing Common Metals: Steel, Aluminum, and Copper for Cost-Performance Balance?

When budgets are tight, people default to “what we used last time.” That habit quietly taxes every order.

Start from loads and environment. Use low-carbon steel for strength at lowest price, aluminum 5xxx when weight or corrosion demand it, and copper only where conductivity is essential. Tie each choice to a published standard.

How I decide in practice (with sources you can cite)

- Low-carbon cold-rolled steel is my default for most brackets and housings. I call out ASTM A1008/A1008M or EN grades under EN 10130 DC01–DC06 so the mill chemistry, surface class, and formability are controlled. These standards are stable and widely available.

- Aluminum 5052-H32 is my first stop for formed aluminum parts that need corrosion resistance without plating and tight bends. The Aluminum Association’s open resources support recycled content and alloy performance; start at their Recycling hub and Policy Agenda for energy and circularity context.

- Copper (C110/C102) I only choose when I need high conductivity or EMI gasketing. Conductivity is measured against IACS 100%; copper.org explains the baseline and how alloys compare in the [IACS primer](https://www.copper.org/applications/industrial/DesignGuide/selection/elect02.html).

- When strength-to-thickness matters, I test HSLA before jumping to stainless. HSLA 340–420 can allow a 10–20% thickness drop if bend radii and weld specs permit. I keep bend radii ≥ 1.5×t on first trials and verify with coupons.

If you want me to compare these choices against your geometry, drop the STEP file via our Quality Control page and I will return a thickness and grade recommendation with forming notes.

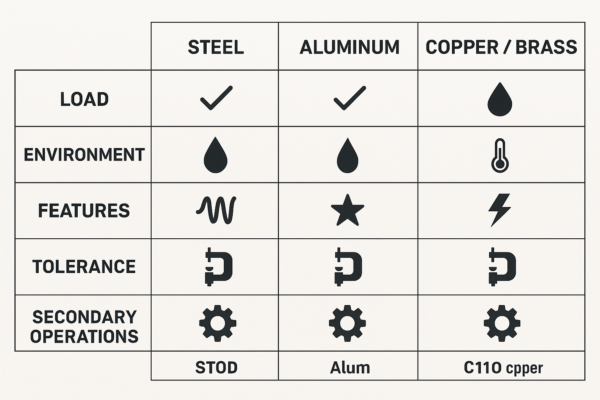

Quick orientation table I use on day one

| Factor | Low-Carbon Steel (A1008 / DC grades) | Aluminum (5052-H32, 5754) | Copper/Brass (C110/C260) |

|---|---|---|---|

| Relative \$/kg | Low | Medium | High |

| Strength-to-cost | High | Medium | Low (unless conductivity needed) |

| Formability | Good (DQ/BH/HSLA options) | Good (5052 best) | Good (brass) to medium (pure copper) |

| Springback | Medium | High | Low-Medium |

| Corrosion bare | Low | Good (5052) | Good (brass), copper tarnishes |

| Weldability | Good | Good (alloy dependent) | Variable; many brasses braze well |

| Conductivity | Low | Low | Very high |

| EMI/RFI | Medium with plating | Low | Very high |

| Tool wear | Low | Low | Medium (oxides) |

| Scrap value | Medium | Medium-High | High |

Optimizing Thickness and Coatings: Avoiding Over-Engineering and Extra Expenses?

I see drawings that double thickness “just to be safe.” That doubles cost too.

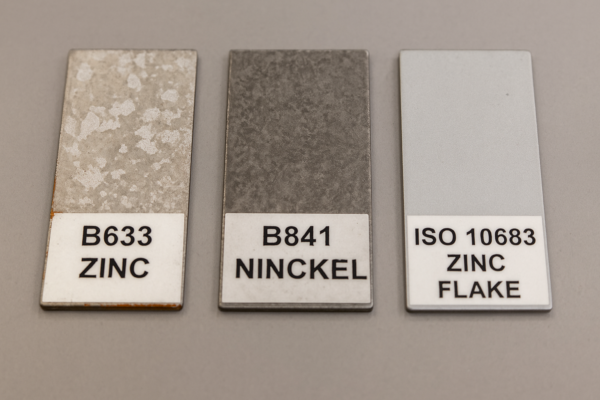

Size sheet thickness to stiffness and dent resistance, not fear. Use bend-radius charts and press feedback. Call coating classes from standards like ASTM B633 (zinc), ASTM B733 (electroless Ni-P), ASTM B841 (Zn-Ni), and ISO 10683 (zinc-flake). Validate corrosion with ASTM B117 or ISO 9227.

My simple math and tests (you can copy them)

- Stiffness scales with t³. Going from 1.0 mm to 1.2 mm raises stiffness \~73% [(1.2³ / 1.0³) ≈ 1.728], but adds 20% mass and material spend. I share this math on quotes so we decide with eyes open. Instead of up-gauging, I add a shallow rib, hem, or hat feature to raise moment of inertia without permanent cost in every kilogram.

- Bendability depends on alloy, temper, and grain. For aluminum, 5052-H32 bends much tighter than 6xxx tempers. For steel, DC04/DC05 or A1008 CS Type B bend cleaner than high-carbon variants. I confirm radii and springback with a coupon set and a quick calculator, for example SSAB’s BendCalc.

-

Coatings should be classes, not adjectives.

- Zinc on steel: specify ASTM B633 Type and thickness class, then state the corrosion test and hours using ASTM B117 or ISO 9227.

- Zinc-nickel: move to ASTM B841 when heat or salts demand it.

- Electroless nickel: ASTM B733 for uniform coverage in recesses.

- Zinc-flake (fasteners): ISO 10683 avoids hydrogen embrittlement risk.

- Paint/E-coat: measure dry film with ASTM D7091 (magnetic/eddy), and check adhesion with ASTM D3359 cross-hatch. If you need a paint system guide for outdoor steel structures, EN ISO 12944 is a helpful framework.

- Compliance matters. I keep RoHS 2011/65/EU on drawings so passivations stay compliant.

| Function | Typical Finish | Why | Primary Reference |

|---|---|---|---|

| Indoor steel brackets | Zinc per ASTM B633 | Lowest cost; conductive | B633 + B117/ISO 9227 |

| Harsh road/engine | Zn-Ni per ASTM B841 | Longer life at heat | B841 + B117/ISO 9227 |

| Fasteners / H₂ risk | Zinc-flake per ISO 10683 | No hydrogen embrittlement | ISO 10683 |

| Wear & recess coverage | EN per ASTM B733 | Uniform deposit; wear | B733 |

Go Deeper: Formability and Edge Quality (n-value, r-value, HER)

I reduce forming risk and scrap by checking three simple material indicators that many RFQs ignore.

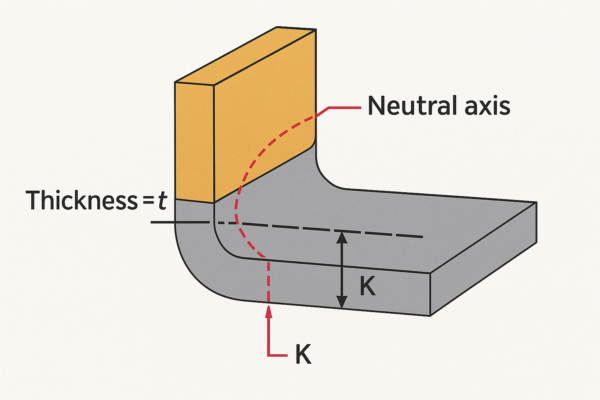

n-value, r-value, and hole expansion ratio (HER) tell me how far I can push stretch and draw, and how clean edges must be before forming.

- n-value (strain hardening): higher n means better stretch-formability and a wider safe window. Tensile test standards ISO 6892-1 or ASTM E8/E8M provide the method; ISO 10275 covers n-value.

- r-value (Lankford): higher r reduces thinning in draws. ISO 10113 defines the calculation.

- HER (hole expansion): a conical punch expands a pre-pierced hole; higher % means better edge stretch resistance. ISO 16630 is the standard.

I ask mills or service centers for these values on new grades. If they cannot share, I run quick shop tests. I log the numbers in our Quality Control file so future coils match behavior.

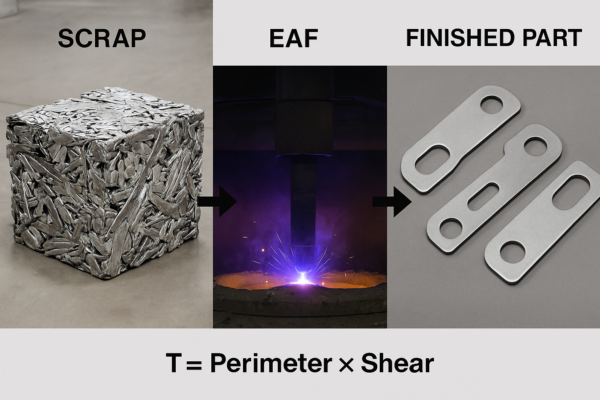

Process Math That Keeps Quotes Real (Tonnage, Draw Reductions, BHF)

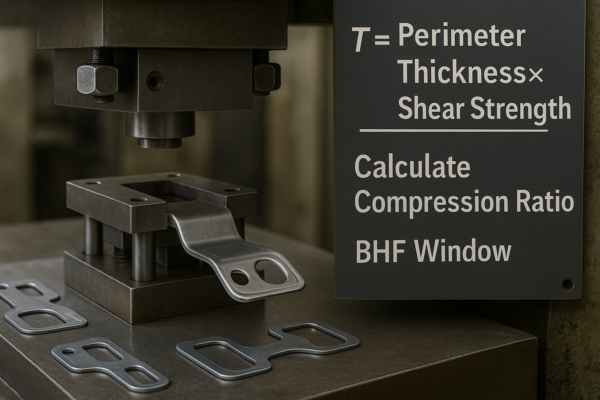

I do not guess at tonnage or draw feasibility. I write three numbers before I quote.

Shear tonnage, draw reduction per stage, and blankholder force (BHF) keep me honest about press choice, die life, and scrap risk.

- Shear tonnage:

T ≈ Perimeter × Thickness × Shear strength.

For low-carbon steel, I use 250–350 MPa shear as a first pass. I size press capacity with 20–30% headroom. - Draw reduction per stage: I keep first draws below ≈ 45% diameter reduction on mild steel and adjust for alloy and lube. If I must exceed, I add draw beads or an intermediate anneal.

- Blankholder force (BHF): too low causes wrinkling; too high causes tearing. I start with 0.2–0.4 × punch force for mild steel cups and tune in trials.

I choose tool steels based on wear and edge quality needs. For long runs in mild steel, D2/SKD11/DC53 with TiCN/TiAlN coatings is my default. For copper/brass, I often add a light polish and a different lube to fight galling.

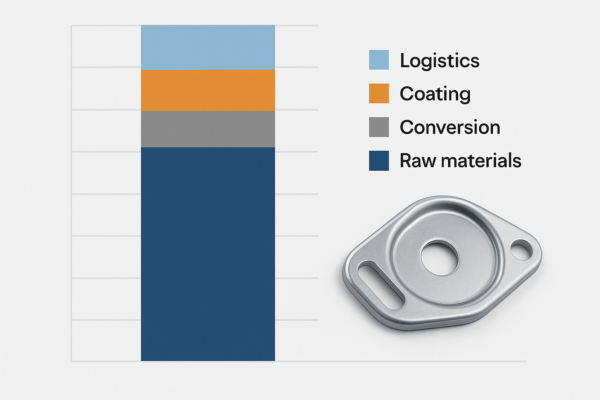

Recycled and Eco-Friendly Metals: Cost and CO₂ Wins (With Proof)

I do not buy “green” labels without numbers. Recycled content and EAF steel can be real cost and CO₂ wins, but only if specs allow.

Use EAF steel and recycled aluminum where surface and strength allow. Cite credible bodies so purchasing and sustainability teams are aligned.

- Steel: worldsteel explains the circular role of scrap and the impact of EAF routes; see their circular economy overview and the scrap fact sheet. When cosmetic class allows, I specify EAF-sourced coils and ask for recycled % on mill certs.

- Aluminum: the Aluminum Association shows recycled aluminum saves \~95% of the energy vs. primary production; see their Recycling hub. For formed panels in 5052-H32, I skip plating and use conversion coat + paint if appearance matters.

- Copper: conductivity is set by IACS; the Copper Development Association’s design guide is where I confirm trade-offs when moving to brass or plated steel for cost.

If you want CO₂ reporting with your quote, I add a simple “route delta” note in the PDF and link the source. I keep that record under Blog case studies so your team can share it upstream.

Bulk Purchasing and Supplier Partnerships: Lowering Raw Metal Risk

Material price is a rollercoaster. If we ride it without seatbelts, quotes explode or stall.

I separate base-metal price risk from value-add. I link coil costs to public indices (LME for aluminum, CME HRC for steel), wrap them with caps/floors, and use VMI or blankets for stable flow.

- Index the metal: use LME Aluminium with the Official Price methodology, and CME U.S. Midwest HRC (CRU) for steel. We fix a monthly average window.

- Fix the processing: stamping, coating, and packing are fixed. Only metal floats. This matches how we present costs in How Much Does Metal Stamping Cost?.

- Blankets and VMI: a blanket sets the framework; VMI smooths releases and reduces stockouts. See CIPS’s overview of inventory types & costs (includes VMI) and Berkeley’s note on Blanket POs. If you use SAP, this SAP VMI explainer aligns with what your procurement team expects.

- ISTA-based packaging: I set pack rules and test by ISTA 3A/3B/3E so we do not over-pack or ship dents. We file the test record in your FA report under Quality Control.

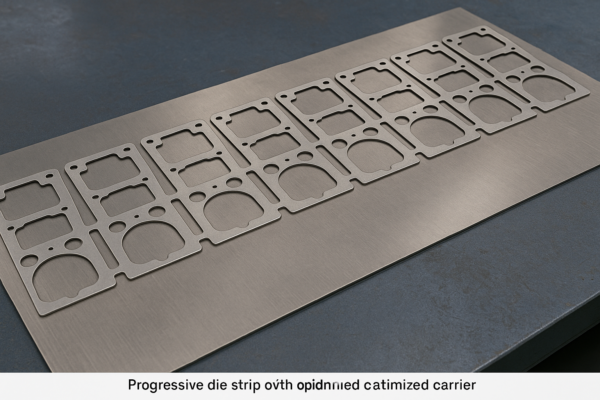

DFM That Cuts Cost: Tolerances, Radii, Features, and Nesting

Design drives cost more than purchase timing. Small print changes save more than big price fights.

I widen tolerances where fit allows, choose sane bend radii, simplify features, and align design with coil and die limits. I show nesting proof with real strip layouts.

- Tolerances: use ISO 2768-m as default unless a feature is functional. Move holes away from bends ≥ 2×t. Round internal corners to ≥ 0.5–1.0×t.

- GD\&T where it matters: use ASME Y14.5 position on mating holes and datum surfaces; gauge functional faces rather than raw bend angles.

- Nesting: match strip width to common slit sizes; rotate parts if grain allows; share webs in progressive dies; align pierce patterns to common pitch. I include a nest snapshot in your Stamping Parts quote to show yield.

- Edge quality: if HER is low, I switch to fine-blanking on critical edges or add a pre-pierce + resize pierce station to raise edge quality.

| Print Item | Common Problem | Simple Change | Why It Saves |

|---|---|---|---|

| Hole ±0.05 mm | Unneeded tightness | Move to ±0.15–0.20 mm | Faster hits, less rework |

| Sharp internal corner | Crack starter | Add 0.5–1.0×t radius | Stops cracks, longer die life |

| PEMs everywhere | High hardware cost | Use tabs/lances where non-structural | Less cost, faster assembly |

| Deep draw in hard temper | Tearing | Form softer temper or add draw bead | Stable forming, lower scrap |

| Random hole pattern | Poor nesting | Align to common pitch | Better nesting, faster pierce |

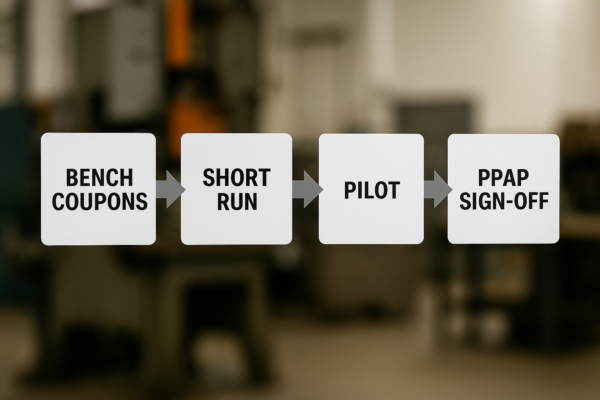

Validation Flow: Prove the Material Swap Fast (PPAP-Ready)

A cheaper material is useless if field returns jump. I validate fast, cheap, and with the right tests.

I follow bench tests → short-run trial → customer pilot. I choose tests that match risks and file results into PPAP/APQP so purchasing and quality can sign off.

- Bench tests: bend coupons (target radius), hole expansion (ISO 16630), Z-bend for springback, salt spray (ASTM B117/ISO 9227), and simple wear checks (ASTM D4060 Taber if painted). Tensile per ISO 6892-1 or ASTM E8/E8M as needed.

- Short run: track scrap, burr height, press speed, and tool wear; compare to baseline. Measure plating thickness (magnetic per ASTM D7091 or XRF per ASTM D3359).

- Pilot: ship 50–300 parts; get assembly feedback; confirm Cpk/Ppk ≥ 1.33 on critical dims; submit FAIR with certs. We keep FMEA, Control Plan, and MSA light but complete.

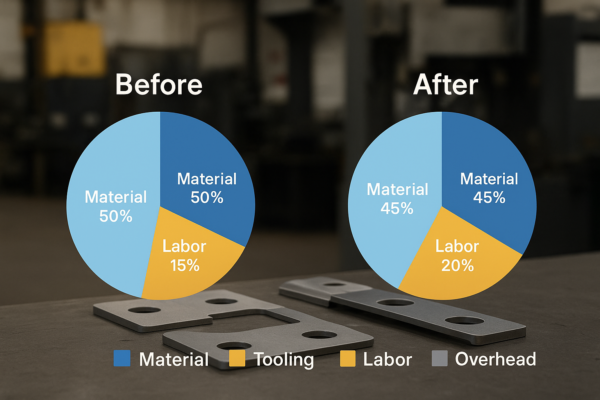

Real Cases From My Desk (Numbers and Lessons You Can Re-Use)

Case 1 — Indoor bracket, high volume

We moved from 1.2 mm A1008 to 1.0 mm DC03 plus a shallow rib. Finish: zinc per ASTM B633 with clear passivate. Corrosion target: ISO 9227 240 h. Cost result: −8% material, −4% cycle time. Pack tested to ISTA 3A; damage claims fell to zero. We documented the approach under Blog.

Case 2 — Outdoor telecom door

We replaced 1.6 mm steel + powder with 2.0 mm 5052-H32 + conversion coat + paint (no plating). Weight: −32% vs. steel. Field corrosion: clean after a season. Hardware remained plated steel per ASTM B633. Details live in Surface Treatment.

Case 3 — Fasteners near brakes

We switched from bright zinc to zinc-flake per ISO 10683 on 10.9 bolts and springs. Salt spray: ISO 9227 720 h. No hydrogen embrittlement risk. Warranty corrosion passes. QC data is attached in the Quality Control pack.

RFQ and Drawing Notes That Prevent Cost Creep (Copy-Ready)

You can paste these lines, as is, into your drawing or RFQ. They keep costs down without risk and help us quote faster.

- Material: “Steel, cold-rolled, ASTM A1008 CS Type B or EN 10130 DC03, t = 1.0 mm ± 0.05. Alternates allowed if equal or better in yield, elongation, n/r values, and die formability.”

- Aluminum alternate: “5052-H32 1.2 mm ± 0.05 if weight/corrosion justify; form across grain.”

- Finish: “Zinc per ASTM B633 Type [ ], Class [ ]; NSS per ISO 9227 [240/480] h. RoHS (2011/65/EU) compliant.”

- Critical features: “Bend IR ≥ 1.0×t (steel) / 1.5–2.0×t (Al). Holes ≥ 2×t from bends. Internal radii ≥ 0.5×t.”

- Measurement: “FAI w/ thickness, hardness, plating thickness (ASTM D7091/D3359).”

- Packaging: “ISTA 3A/3B/3E method per lane; edge guards; VCI for sea freight.”

- Pricing: “Raw metal indexed to LME (Al) / CME HRC (steel) monthly avg; conversion fixed 6–12 months.”

FAQs (Focused on the choices that move cost)

How do I know if A1008/DC grades will bend without cracking at my radius?

Check supplier bend tables or run coupons. SSAB’s BendCalc is a good quick check. I confirm with a trial before cutting full dies.

Is 5052-H32 always better than 6061-T6 for stamped parts?

No. 5052-H32 bends tighter and resists corrosion, so it wins for most stampings. If you need stiffness or machining, 6061 can work, but form in soft temper (T4/O) then age if necessary.

What salt-spray hours should I specify?

Pick hours that mirror your environment and warranty using ASTM B117 or ISO 9227. Overspeced hours waste money.

When should I pick zinc-nickel over bright zinc?

When you face heat, road salts, or long warranties. The deposit is defined by ASTM B841. Use it where duty cycle or temperature justifies it.

Will zinc-flake pass RoHS?

Yes. Modern ISO 10683 systems are hex-Cr-free. Keep RoHS on the drawing so the coater uses compliant passivation.

Is VMI just consigned stock?

No. In Vendor-Managed Inventory, the supplier plans replenishment by your demand signals; ownership terms vary. VMI reduces stockouts and improves turns on steady programs.

My Quick Cost-Sanity Checklist Before I Quote

- Base metal standard set? (A1008 / EN 10130 / 5052-H32)

- Thickness justified with t³ math or reinforcement?

- Bend trials logged with photos? (see BendCalc)

- Finish class by standard? (B633 / B841 / B733 / ISO 10683)

- Corrosion test hours realistic? (B117 / ISO 9227)

- RoHS note present? (2011/65/EU)

- Index clause for raw metal? (LME / CME HRC)

- ISTA packaging method matched to route? (3A/3B/3E)

- Internal hand-off ready? (FMEA, Control Plan, PPAP folder in our Quality Control)

Conclusion

Choose the cheapest metal and coating that pass real tests. Lock specs to standards. Index the metal, fix processing, validate with coupons and pilots, then ship on time with less scrap.

About the Author

I am the lead manufacturing engineer at Prime — One-Stop Metal Custom Parts Factory. I have spent over 30 years building stamped, welded, cast, and fastened assemblies for global clients. We founded Prime in 1993 and hold ISO international quality certification. My work bridges design and the pressroom. I run material trials, review die design, and negotiate index-linked purchases, so your drawings become safe, reliable parts without bloat. Our mission is simple: provide top-notch industrial hardware and support global industrial growth. We ship fast, customize logos, and stand behind consistent quality. If you buy Siemens electronic parts, brackets, shields, or precision stampings, I understand your pain points: strict packaging, volatile seasons, and inconsistent quality. I write these guides in the first person because I own the outcomes; learn more on our About page, reach me via Contact, and browse related work in our Blog.

Brand: Prime — One-Stop Metal Custom Parts Factory · Website: https://primefabworks.com/ · Focus: stamping, welding, casting, fasteners, CNC, plastic parts · Strengths: ISO-certified quality, fast delivery, custom logos, exhibition and Alibaba presence.