Top Material Selection Strategies to Reduce Costs in Custom Plastic Parts?

Resin prices1 rise fast, and margins shrink. I feel that pressure too. So I cut cost with smarter material choices2.

Pick the lowest total cost polymer1 that meets function. Compare resin price, cycle time, scrap risk, tooling fit, and any finishing steps. Then verify results with dimensional and reliability tests2 before release.

I will share clear steps, field data, and shop stories. And I will show how Prime turns choices into savings1. So you can act now and protect margins2.

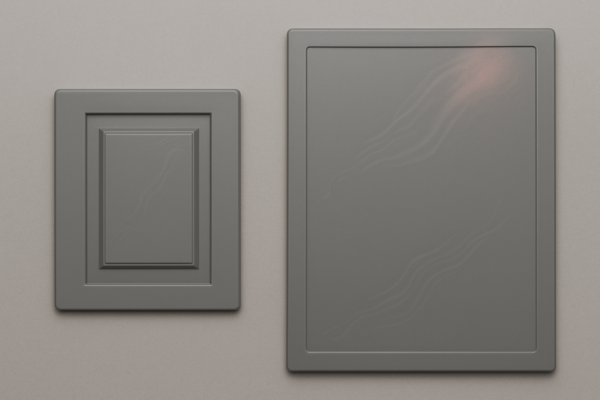

Comparing Common Polymers: ABS, Nylon, Polycarbonate, and Their Cost Benefits?

Many teams choose famous grades first and overpay. I did that before, and I learned. So I compare polymer families1 first, then shortlist grades2.

ABS suits general housings with good flow and finish. Nylon suits wear and heat. Polycarbonate suits high impact or optics. I compare unit price1, shrink, flow, cycle time2, and finishing steps to find the real low cost.

ABS1 wins when impact is moderate and cosmetics matter. It paints well, and it welds cleanly. It often cycles faster, so it cuts cost2.

Nylon wins when friction and heat rise. It brings wear resistance1, and it stays strong. But it absorbs moisture2, so I adjust tolerances.

Polycarbonate1 wins when impact is extreme or windows need clarity. It resists breakage well. But it scratches easily, so I plan hard coats2.

Quick comparison

| Polymer | Typical Use | Strength | Impact | Heat | Finish | Relative Resin Cost | Cycle Time |

|---|---|---|---|---|---|---|---|

| ABS1 | Housings, brackets | Medium | Medium | Medium | Easy | Low | Short |

| Nylon (PA6/PA66)2 | Gears, clips | High | Medium | High | Medium | Medium | Medium |

| PC | Guards, lenses | High | Very High | Medium | Harder | High | Long |

Fast cost levers

- Choose ABS for covers when PC is not required.

- Use PA6 GF1 for stiff clips to replace metal.

- Blend PC with ABS when pure PC is overkill.

- Lock texture early2 to avoid rework and repaint.

- Align gates with flow to cut scrap quickly.

Dive Deeper

Total cost beats resin price alone

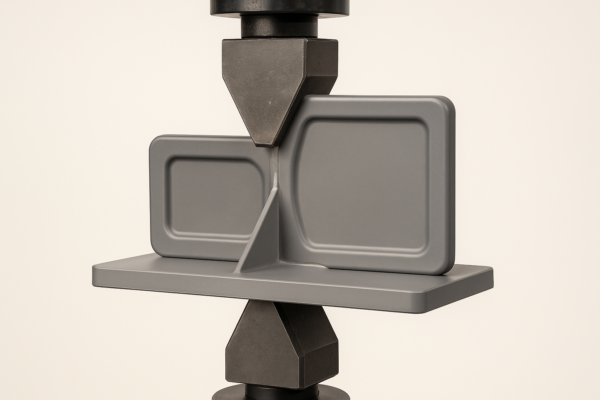

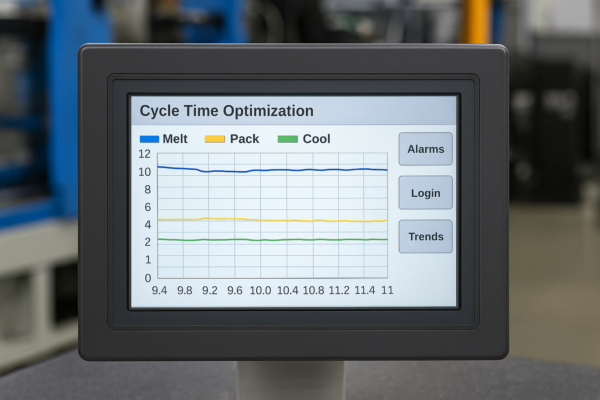

I learned this truth on a handheld enclosure line. The team wanted pure PC for a “premium feel,” and the resin bill climbed. The cycle time1 rose sharply because the melt temperature ran higher, and cooling took longer. The scrap rate also increased because the texture blushed near the gate. So I proposed PC-ABS2 with a micro-bead texture and a gate shift. Impact performance stayed strong, and drop tests passed with margin. The cycle time1 fell by six seconds per shot, and the scrap rate dropped below one percent. We did not change the mold steel, and we kept the same assembly plan. Therefore the total cost per unit improved even with a mid-priced blend. Clients saw no cosmetic loss, and marketing still loved the look. I now run that same checklist on new RFQs, and I spot savings early.

Moisture and tolerances with Nylon

Nylon absorbs water1 and grows slightly, and it can surprise teams. I model that growth in the tolerance stack, and I oversize dry-as-molded press fits by a precise margin. Then I measure parts at ambient, and I also measure at 50% RH. I choose PA662 when I need higher heat deflection, and I keep wall thickness even to control differential shrink. I add small fillets to ease flow and to boost fatigue life around clips and hinges. My team stores Nylon in dry rooms, and we log hopper dew point every shift. We also bag finished parts with desiccants for long sea lanes. So assemblies hold fit in real use, and we avoid late shims and rework. Clients get stable dimensions, and procurement gets stable cost.

Surface finish and secondaries

ABS paints easily1 and needs less primer, and that saves time. PC often needs a hard coat to resist scratches, and I include that step in RFQs. I test ultrasonic weld seams2 early because PC can stress whiten, and I adjust horn profiles. I also polish runners when gloss is critical, and I balance venting to avoid burn marks. These small steps help budgets, and they protect schedules for your launch. I write these notes in the control plan, and I train operators with visual cards. Then the process stays stable, and cosmetic defects stay low.

Balancing Strength, Durability, and Price When Choosing Plastic Materials?

Many buyers chase “maximum strength1” and overspec parts2. I did that once, and I paid double. So I match numbers with real use and geometry.

Define loads, temperatures, chemicals, and life. Set minimum targets1 with safety margin2. Then choose the cheapest grade that meets targets and still runs fast.

My simple scoring model

| Factor | Weight | ABS | PA66 GF30 | PC | PC-ABS |

|---|---|---|---|---|---|

| Tensile/Modulus1 | 0.35 | 3 | 5 | 4 | 4 |

| Impact2 | 0.25 | 3 | 3 | 5 | 4 |

| Heat | 0.15 | 3 | 5 | 3 | 3 |

| Finish/Process | 0.10 | 5 | 3 | 3 | 4 |

| Cost | 0.15 | 5 | 3 | 2 | 3 |

| Total | 1.00 | 3.8 | 4.1 | 3.6 | 3.8 |

Rapid screening

- Quantify load cases, not adjectives.

- Confirm operating and storage temperatures1.

- Check chemicals and UV exposure early.

- Review wall thickness and rib design.

- Add safety factors2 and test quickly.

Dive Deeper

The decision path that saves money

I start with function and exact loads, and I use numbers. I list torque, drop height, and temperature limits with real units. Then I set minimum targets with a safety margin1, and I record pass criteria. Next, I tune geometry before I upgrade resin, and I focus on stiffness by design. Thin walls need high-flow grades, and thick walls need low shrink and strong venting. Ribs add stiffness better than flat plates, and they save weight. So I improve structure first, and I keep the material simple. I audit process speed2 next, because short cycles cut cost fast.

Impact of Recycled and Bio-Based Plastics on Cost and Sustainability?

Many customers want greener parts1 and lower cost2. I support that goal, and I also protect fit, safety, and brand look.

Recycled and bio-based plastics1 can reduce resin cost2 and carbon. They need tight specs, stable sources, and trials. So I qualify them with data and clear limits.

Options and trade-offs

- Post-industrial regrind gives stable quality in most cases.

- Post-consumer resin1 needs stronger screening and additives.

- Bio-based blends2 work in non-structural parts today.

- Hybrids balance stability, strength, and price for covers.

Quick view

| Material Path | Cost Impact | Property Stability | Typical Use |

|---|---|---|---|

| PIR Regrind 10–20%1 | Lowers modestly | High | Housings, trays |

| PCR ABS/PC 20–50% | Lowers or neutral | Medium | Covers, panels |

| Bio-based PLA blends2 | Varies | Medium-Low | Trays, packaging |

| Engineered PCR Nylon | Neutral to higher | Medium | Low load clips |

Dive Deeper

How I qualify recycled content without risk

I align on function and safety class first, and I keep records. If the part is safety-critical1, I keep virgin or tight PCR specs. Then I define “recycled” in writing, and I state percentage, source, and allowed variance. I tie every lot to a COA and a batch label, and I test tensile, impact, MFR, and color delta-E on first shipments. I also log moisture before drying, since PCR often holds more water. I stabilize the process next, and I extend drying times with dew point checks. I open the gate when flow drops, and I raise pack pressure carefully to control sinks. I adjust hold time to avoid voids, and I track results in SPC charts2.

Working with Suppliers: How Bulk Material Sourcing Lowers Expenses?

Many companies buy resin per job and lose leverage. I saw that pattern often, and I fixed it. So I bundle demand1 and plan quarterly with partners.

Bulk sourcing drops unit price, stabilizes lead time, and reduces changeovers. I align forecasts with a trusted factory1. Then I lock tiers, parameters, and safety stock.

Where savings come from

| Lever | Typical Effect | What I Do |

|---|---|---|

| Volume tiers1 | 3–15% lower | Combine SKUs and commit quarterly |

| Pre-dry and silo | Faster cycles | Stage resin and standardize parameters |

| Color masterbatch | Less waste | Color at press, not pre-compound |

| Blanket orders | Short lead time | Hold safety stock with triggers |

| VMI/Consignment2 | Smoother cash flow | Pay as we pull, not on receipt |

Communication that prevents delays

- Share drawings, CTQs, and PPAP or IQC plans early.

- Agree on moisture control1 and packaging.

- Align on INCOTERMS and backups.

- Set plan B for shipping lanes and carriers2.

Dive Deeper

How Prime reduces material cost without quality risk

I run ten production lines at Prime, and I see demand swings. I group programs that use the same resin families, and I book bulk lots with ISO-certified injection molding factory1 sources. We secure price tiers and safer lead times, and we hold safety stock in dry rooms2. So presses keep running, and unit prices stay stable across seasons. I set standard drying, melt, and cooling profiles per resin, and I train operators with simple visual cards. Setup times drop, scrap drops, and cycle times improve across shifts.

FAQs: Smart Plastic Material Choices for Cost and Quality?

What material cuts cost for general housings?

ABS usually wins on value, and it often needs shorter cycles1. It flows well, and it finishes clean2.

When should I choose PC-ABS over pure PC?

I choose PC-ABS when I need high impact1 and shorter cycle2. The blend balances cost, toughness, and cosmetics.

Does Nylon always beat ABS for strength?

Nylon1 wins in wear and heat, and it handles friction. But ABS2 can win on finish and price.

How much recycled content is safe for housings?

I start at 10–30% PCR1 or PIR, and I test welds, impact, color, and MFR2 before release.

Can recycled resin pass ISO audits and PPAP?

Yes, with locked specs, COAs, and traceability. Our ISO-certified plastic parts manufacturer1 team supports audits and documents2.

Do glass fibers reduce cost or only add strength?

Glass allows thinner walls1 and fewer ribs, and it saves weight2. So total part cost can fall.

What if my part needs clarity and scratch resistance?

I use PC with a hard coat1, and I redesign windows2 to protect touch areas. Then wear drops.

How do bulk buys lower my price today?

We bundle SKUs, set tier triggers, and hold safety stock1. So your unit price2 and lead time improve.

Can Prime support metal and plastic in one project?

Yes. We handle CNC parts precision machining1, custom stamping parts supplier2 work, and plastics in one plan.

Conclusion

Smart polymers1, strong trials, and bulk sourcing2 cut costs while keeping strength, finish, logistics, and delivery dates reliable.

Prime is a custom plastic parts supplier in China with ten production lines. We also provide CNC parts precision machining, ISO-certified casting parts manufacturer solutions, fasteners, welding parts, and custom stamping parts supplier services. We sell B2B only, and we ship quickly to North America, Europe, the Middle East, Australia, and more. We keep packaging strict, and we keep communication clear and fast.

Please contact Prime today. Send an inquiry on our website for a free consultation, quote, and custom plan. We move quickly, and we keep quality steady. With our one-stop team, you save time, reduce risk, and protect your margins.

Helpful search phrases: custom plastic parts supplier China, ISO-certified injection molding factory, CNC parts precise machining, ISO-certified casting parts manufacturer, PC-ABS housing cost reduction, bulk resin sourcing China.

-

Explore this link to understand how smart polymers can revolutionize industries with their unique properties. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about bulk sourcing strategies that can significantly lower production costs while maintaining quality. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩