Top-Rated Custom Forging Service Providers in 2025: B2B Buyers’ Ultimate Guide

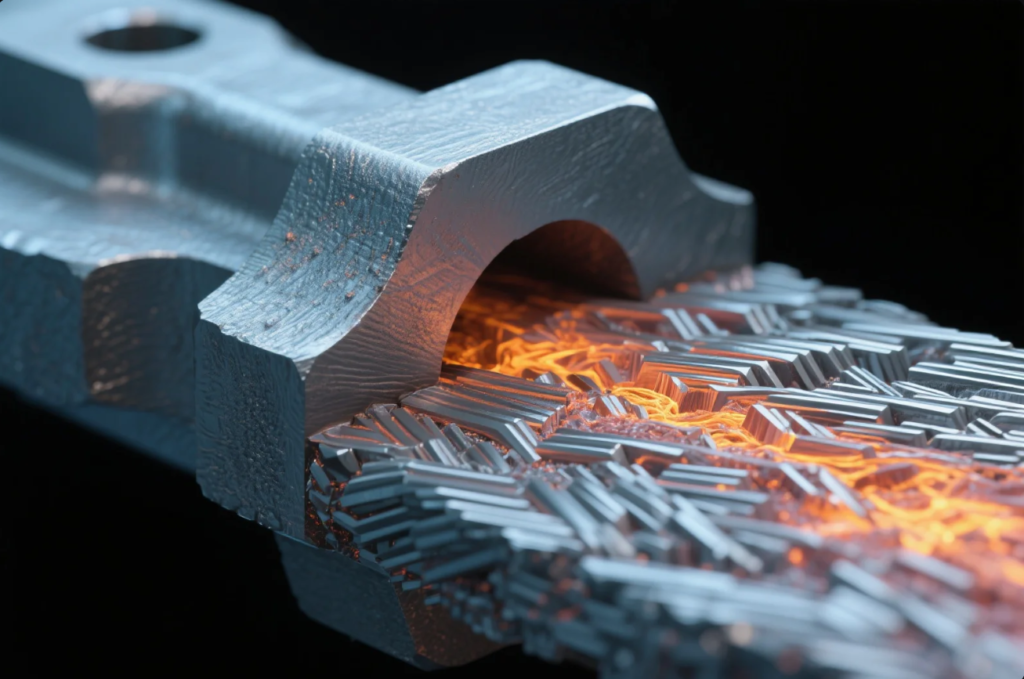

How Custom Forging Enhances Strength and Performance in Metal Parts

Custom forging is the process of shaping metal under high pressure to achieve high strength, structural integrity, and fatigue resistance. Unlike casting or machining from bar stock, forging improves grain flow, removes voids, and aligns internal structure with external load paths.

Benefits of Forged Parts:

- Superior tensile and yield strength

- Greater impact resistance and shock load endurance

- Tighter dimensional accuracy and reduced porosity

- Ability to customize shapes, materials, and tolerances

Whether for automotive suspension or industrial machine arms, forged components consistently outperform other manufacturing methods in high-stress applications.

What to Look for in a B2B Forging Partner: Certifications, Tolerances & More

Choosing the right B2B forging supplier means balancing technical capability, certifications, and communication.

Key Evaluation Criteria:

| Attribute | What to Check | Why It Matters |

|---|---|---|

| Certifications | ISO 9001, IATF 16949, AS9100 | Ensures quality control and traceability |

| Tolerances | ±0.05mm typical, tighter with CNC | Affects part interchangeability |

| Tooling Support | CAD + DFM, custom die making | Lowers errors, speeds up development |

| Materials | Steel, aluminum, brass, specialty | Allows flexibility across industries |

| MOQ & Lead Time | Customizable MOQ, 2–4 week lead | Adapts to scaling projects |

Top Global Forging Partners to Consider:

- Prime Custom Parts – Flexible MOQ, full CNC, ISO 9001, rapid shipping

- Scot Forge – USA-based, defense-grade certified

- KOBE Steel – High-tolerance Japanese forging for EVs

- Bharat Forge – Leading Indian OEM tier-1 supplier

Good partners provide design feedback, precise measurement reports, and multilingual support teams.

Top Industries Using Custom Forged Parts in 2025 and Their Suppliers

In 2025, demand for forged parts has expanded beyond automotive into aerospace, energy, robotics, and medical sectors.

Industry-Wise Application Table:

| Industry | Forged Components | Sample Supplier |

|---|---|---|

| Automotive | Control arms, axle shafts, wheel hubs | Prime Custom Parts |

| Aerospace | Landing gear, turbine disks | Scot Forge |

| Oil & Gas | Flanges, valves, connectors | Larsen & Toubro |

| Construction | Hydraulic linkages, crane parts | Bharat Forge |

| Robotics & AI | Joint housings, actuators, aluminum arms | KOBE Steel |

| Medical Devices | Titanium surgical tools, implant bases | POSCO |

The need for ISO-class quality with custom engineering is leading buyers to rely on suppliers with multi-process integration.

Insider Tips to Get the Best Quote from Global Custom Forging Experts

Many buyers overpay for forgings due to unclear drawings, missed specs, or poor tooling planning. Here’s how to avoid it:

B2B Sourcing Tips:

- Send clear 2D + 3D drawings: Include material, finish, tolerances

- Specify usage scenario: Structural vs cosmetic affects price

- Request shared tooling: Save mold cost on grouped parts

- Be flexible on packaging: Neutral options lower fees

- Use supplier’s stock alloys: Avoid importing exotic materials

- Plan orders with buffer: Air freight adds up, use sea when possible

- Ask for sample with inspection report: Ensure specs before mass run

Prime Custom Parts and others offer free DFM feedback and weekly updates — leverage that early to avoid issues later.

FAQs

-

What’s the lead time for forged parts?

Usually 2–5 weeks depending on volume and post-processing. -

What’s the MOQ?

100–500 pcs for most alloys and sizes. -

Do you provide finish treatments?

Yes — anodizing, phosphating, zinc plating, powder coating. -

Can I order by annual contract?

Yes. Forecast orders reduce unit price and secure priority production slots. -

How are parts packed for export?

Anti-rust bag, foam wrap, ISPM-15 pallets. Custom barcode labeling is optional. -

Do you support urgent orders?

Yes. Prime and others can ship samples in 7 days and mass batches by air. -

Can you provide testing reports?

Yes. Reports include CMM, hardness, tensile, and ultrasonic inspection. -

How long do forging dies last?

5,000–50,000 uses depending on alloy and part complexity. -

Are forged parts more eco-friendly?

Yes. Forging has lower scrap rates and often reuses recyclable alloys. -

Can I visit your factory?

Yes. Prime welcomes visits or third-party inspections.

Contact Us

🌐 Website: https://primecustomparts.com

📩 Email: [email protected]

Submit your drawings or project inquiry now. Our engineers will respond within 12 hours with a professional quote, timeline, and support plan.

Conclusion

Forging remains the top choice for strength-critical, performance-driven components. In 2025, B2B buyers should prioritize certified suppliers with advanced forging lines, responsive teams, and global logistics capabilities.

Partner with Prime Custom Parts — your one-stop custom metal component expert. Get started today with a free consultation, rapid sample, and tailored quote.