Top-Rated Custom Plastic Fabricators Serving Industrial OEMs in 2025

Top-Rated Custom Plastic Fabricators Serving Industrial OEMs in 2025

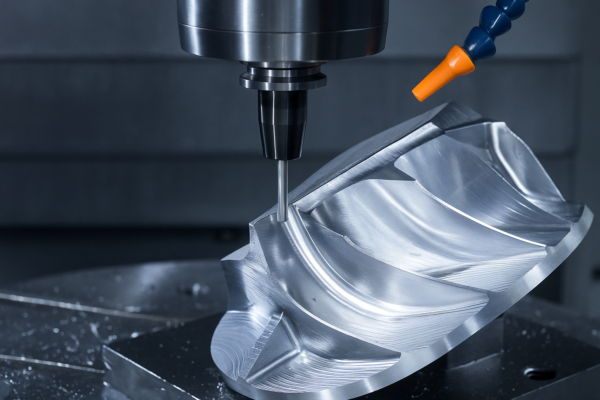

Industrial OEMs require durable, precision-engineered plastic components for everything from enclosures and housings to fluid control parts and high-performance insulators. In 2025, global competition and sustainability goals make it more critical than ever to choose the right custom plastic fabricator.

This guide presents the most trusted plastic fabrication companies and provides insight into material selection, compliance standards, and supplier evaluation.

Which Industries Rely Most on Custom Plastic Fabrication?

Custom plastic fabrication supports a wide range of OEM industries, including:

- 🚗 Automotive – electrical housings, dashboards, fluid system parts

- 🏭 Industrial Equipment – machine guards, gear housings, handles

- ⚡ Energy & Power – insulators, cable brackets, transformer bushings

- 🏥 Medical & Diagnostics – trays, enclosures, sensor housings

- 🚀 Aerospace – lightweight ducting, panels, composite fixtures

- 💧 Water & Fluid Systems – pumps, valves, manifolds

How to Assess Certifications and Compliance for OEM Projects

When selecting a supplier for industrial OEM parts, verify these credentials:

- ✅ ISO 9001:2015 – General quality management

- ✅ IATF 16949 – Automotive OEM parts compliance

- ✅ ISO 13485 – Medical device components

- ✅ UL94 / RoHS / REACH – Material fire resistance and environmental compliance

- ✅ FDA 21 CFR – Medical-grade material validation

- ✅ PPAP / FAI / CPK – Production part approval & statistical process control

Prime Custom Parts complies with major international standards and provides documentation packages tailored to each industry’s compliance demands.

What Materials Are Used in Industrial-Grade Plastic Parts?

Choosing the right material is critical to meeting performance expectations. Commonly used industrial plastics include:

| Material | Properties | Common Uses |

|---|---|---|

| ABS | Tough, cost-effective | Enclosures, panels, brackets |

| Nylon (PA6/PA66) | Wear-resistant, chemical stable | Bushings, gears, cable holders |

| Polycarbonate (PC) | High impact, heat-resistant | Machine covers, light lenses |

| PEEK | High-temp, chemical resistant | Aerospace, medical, electronic insulators |

| Polypropylene (PP) | Lightweight, corrosion-resistant | Water system parts, valves |

| PVC | Flame retardant | Cable ducts, conduits, piping |

📌 Many suppliers also offer filled or reinforced grades, such as glass-filled nylon for structural applications.

Benefits of Partnering with an End-to-End Plastic Manufacturer

OEMs benefit significantly from working with fabricators offering complete services:

- 🔧 Mold Design + Tooling – Ensures design-for-manufacturability

- 🏭 Plastic Injection + Machining – Combines high volume with precision

- 🤝 Assembly + Packaging – Reduces vendor fragmentation

- 📊 Quality Control & Reporting – CPK, SPC, dimensional reports included

- 🌐 Global Export Support – Customs documents, certificates, and logistics

📌 Prime Custom Parts provides all-in-one services across plastic molding, CNC processing, and stamping, tailored for OEM buyers in North America, Europe, and the Middle East.

Top Custom Plastic Fabricators for OEM Projects in 2025

| Company Name | Country | Website | Notable Strength |

|---|---|---|---|

| EVCO Plastics | USA/China | Global high-volume fabrication | |

| Plastikon Industries | USA | Medical and automotive integration | |

| Rosti Group | Sweden/Asia | Tooling, molding, assembly at scale | |

| Stack Plastics | USA | Aerospace and tight-tolerance fabrication | |

| Prime Custom Parts | China | Full-service OEM plastic + metal integration | |

| Technoplast India | India | ODM solutions for industrial plastics | |

| C\&J Industries | USA | Cleanroom molding + device assembly | |

| MGS Manufacturing | USA | High-precision molding + tooling systems |

FAQs About Industrial Plastic Fabrication

Q1: What’s the difference between plastic molding and fabrication?

Molding refers to forming shapes from molten plastic (e.g., injection molding), while fabrication may also involve machining, bending, or welding plastic sheets.

Q2: Can custom plastic parts replace metal components?

Yes. Engineering plastics like PEEK, Nylon, or PC are now used to replace aluminum or steel in many load-bearing or chemical applications.

Q3: How can I validate part quality before mass production?

Use samples, PPAP reports, FAI (First Article Inspection), and SPC (statistical process control) to confirm quality.

Q4: What is the typical lead time for industrial OEM plastic parts?

Tooling may take 3–5 weeks; sample and production parts typically ship in 1–2 weeks post-tooling.

Q5: Can plastic fabricators offer hybrid assemblies with metal inserts?

Yes, advanced providers like Prime Custom Parts specialize in overmolding, insert molding, and post-molding assembly.

Conclusion: Choosing the Right Fabrication Partner

For industrial OEMs, the right plastic fabrication partner must combine technical depth, material knowledge, and scalable infrastructure. The top suppliers not only deliver tight-tolerance parts but also support global logistics, compliance, and customization.

Prime Custom Parts is a top-tier supplier offering injection molding, CNC, casting, stamping, and plastic fabrication for OEM buyers worldwide. With 10+ production lines, ISO-certified processes, and export expertise, they are trusted by leading B2B clients in automotive, medical, and industrial fields.

Contact Us

📞 Have a plastic fabrication project? Contact our team today:

- 🌐 Website: https://primecustomparts.com

- 📩 Email: [email protected]