Top Trends in Custom Metal Mold Fabrication for High-Volume Production?

Outdated mold techniques hinder production efficiency and profitability.

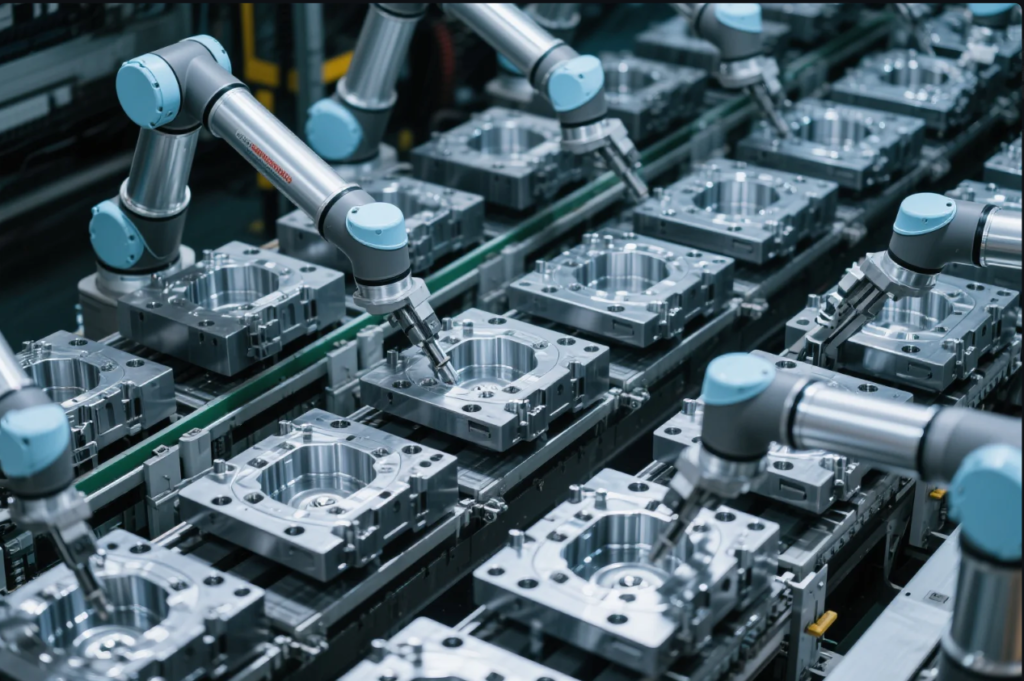

Custom metal mold fabrication is rapidly evolving. Key trends include automation, modular design, and sustainable materials. These advancements enhance production speed, reduce costs, and ensure consistent quality. Companies relying on outdated methods risk falling behind.

What is the future of metal fabrication?

Traditional methods are becoming inefficient due to complexity and slow output.

The future lies in digital manufacturing. CNC machining and additive manufacturing improve mold design speed, flexibility, and quality. These technologies are crucial for high-volume fabrication.

Modular molds speed up production

Modular fabrication systems save time and cut costs. At Prime, we’ve adopted 5-axis CNC centers to deliver tight tolerance parts for various industries.

| Feature | Traditional Mold | Modular Mold |

|---|---|---|

| Replacement Time | 3–5 days | Same-day |

| Cost | High | Lower long-term |

| Customizability | Limited | High |

| Maintenance | Complex | Simple |

What is the future of metal casting?

Old methods create too many flaws. The future focuses on consistency and sustainability.

Metal casting is now cleaner and smarter. Vacuum casting, real-time monitoring, and 3D printed molds are helping reduce waste and defects.

Eco-standards drive the industry

We’ve added low-waste casting lines to meet ISO certifications and EU compliance. This matters for clients in the aerospace and automotive sectors.

| Casting Method | Use Case | Prime Application |

|---|---|---|

| Sand Casting | Large parts | Heavy machinery bases |

| Die Casting | Tight tolerances | Automotive parts |

| Investment Casting | Complex shapes | Aerospace brackets |

| Vacuum Casting | Bubble-free electronics | Electronics enclosures |

What was the most popular process of metal casting?

Sand casting continues to dominate for cost and versatility.

It works well for many applications and has the lowest setup cost. But it isn’t always the best fit for tight tolerances.

Choosing the right method matters

Our clients in HVAC and agriculture often need lighter, thinner parts. We help them compare processes for best outcomes.

| Process | Pros | Cons | Best For |

|---|---|---|---|

| Sand Casting | Cheap, flexible | Lower precision | Simple, large parts |

| Die Casting | Precise, efficient | High tooling cost | Mass production |

| Investment Casting | Complex detail | Time-consuming | Small, precise parts |

What are the two types of molds used in metal casting?

Wrong mold choice increases cost and risk. Know the difference first.

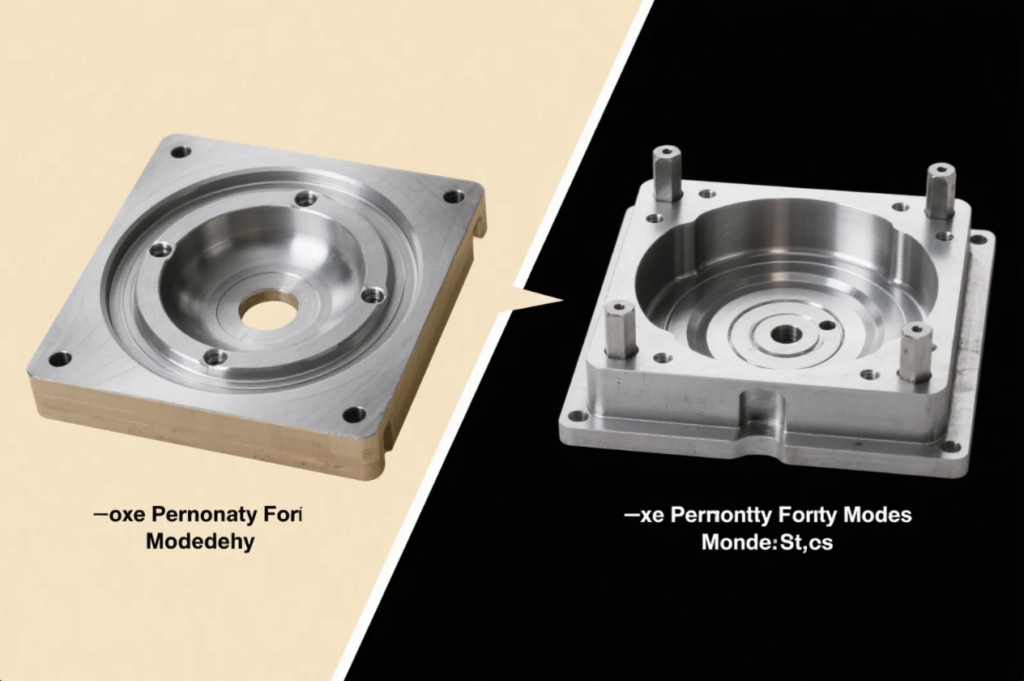

Expendable molds and permanent molds serve different needs. One is ideal for prototypes, the other for mass production.

Choose based on volume and lifespan

At Prime, we help clients pick the right mold based on expected part life, size, and surface finish.

| Mold Type | Material | Lifespan | Applications |

|---|---|---|---|

| Expendable | Sand, Plaster | One-time | Prototypes, large castings |

| Permanent | Steel, Iron | 10,000+ uses | Automotive, Industrial |

FAQs

What materials are used in custom mold fabrication?

Common choices include steel, aluminum, and zinc alloys.

What is the benefit of automated mold manufacturing?

It reduces human error, ensures high consistency, and enables 24/7 operation.

Does Prime offer rapid prototyping?

Yes. We use 3D printing and CNC milling to produce functional prototypes fast.

Which industries use custom metal molds?

Aerospace, automotive, medical, and consumer electronics rely heavily on precision molds.

Is Prime ISO certified?

Yes. We comply with international standards to guarantee product quality and traceability.

Conclusion

Custom metal mold trends enhance speed, cost control, and production consistency across global industries.

Looking for a reliable custom mold fabrication supplier with rapid delivery and ISO certification?

Visit our official website: https://primecustomparts.com

Email us at: [email protected]

We respond fast, deliver faster, and ensure every part meets your expectations.