Top Uses of Custom Metal Molds in Aerospace, Medical, and Energy Sectors?

Precision and consistency define high-stakes sectors like aerospace, medical, and energy. Generic molds can’t meet their tolerances or performance demands.

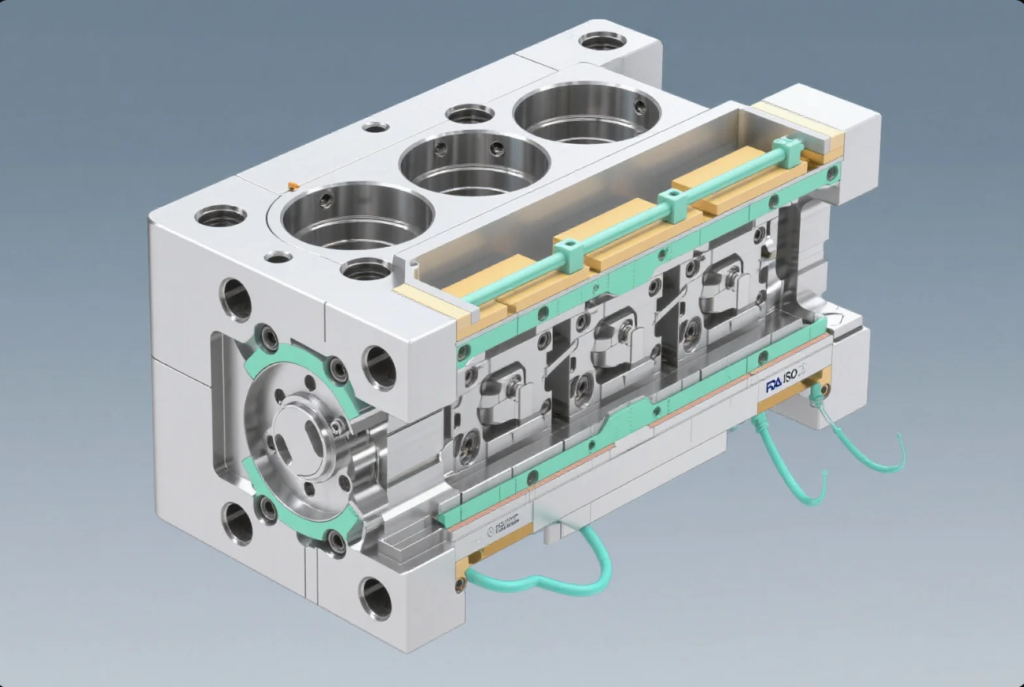

Custom metal molds ensure part uniformity, structural integrity, and regulatory compliance in these mission-critical industries.

This guide explores how precision mold technology supports advanced manufacturing across space systems, surgical tools, and power components.

Why Custom Tooling Matters in Regulated Industries

Sectors like aerospace and medical can’t afford production flaws. A microscopic defect could cause failure in the sky or in surgery.

Custom metal molds meet strict safety, cleanliness, and repeatability standards that generic molds simply can’t achieve.

Key Requirements for Regulated Manufacturing

| Requirement | Why Custom Molds Help |

|---|---|

| Tight Tolerance Fit | Ensures compatibility and no leakage |

| ISO/FDA Compliance | Materials and design meet documentation |

| Consistent Surface Finish | Prevents microbial growth (medical) |

| Lightweight Geometry | Supports fuel efficiency (aerospace) |

At Prime, we provide validated molds for ISO 13485 and AS9100-certified manufacturers. We integrate DFM and risk management during mold design for complete traceability.

Dive into tooling requirements at FDA Medical Device Manufacturing Guide and SAE Aerospace Standards.

Top Aerospace Mold Applications

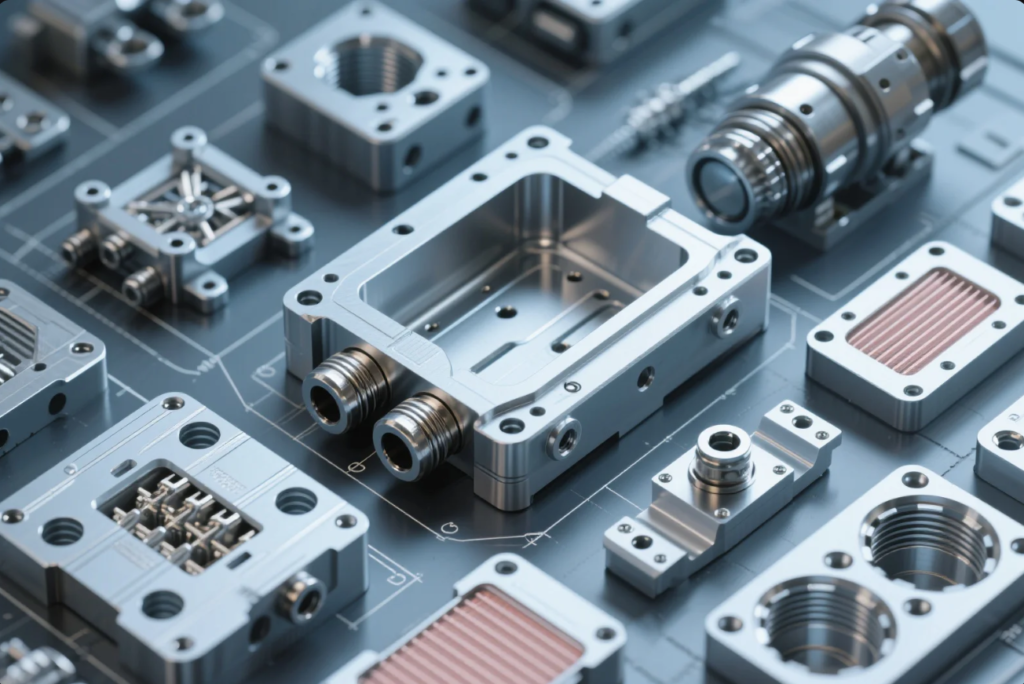

Aerospace parts must be strong, lightweight, and resistant to extreme environments. Molds must deliver micron-level tolerances over long production runs.

From cabin components to engine mounts, custom molds ensure uniformity, weight reduction, and zero-defect output.

Common Molded Parts in Aerospace

| Component Type | Mold Application |

|---|---|

| Composite Brackets | Precision matched aluminum molds |

| Cable Routing Clips | High-heat resistant thermoplastic inserts |

| Ducting Connectors | Multi-cavity high-temp tooling |

| Valve Bodies (Metal) | Investment casting molds with fine detail |

Our aerospace clients use Prime’s 5-axis milled titanium molds for high-pressure sensor frames and lightweight cabin latches. Each mold includes certified steel, CMM reports, and compliance docs.

See more aerospace mold cases at Aviation Week’s Advanced Manufacturing Section and NASA Materials Data.

Custom Molding for Medical Devices

Medical device parts must meet bio-compatibility, sterilization, and particle-free production criteria.

Custom molds provide exact cavity designs, medical-grade surface polish, and modular inserts for cleanroom-compatible production.

Molded Medical Products

| Device Part | Molding Type |

|---|---|

| Syringe Barrels | High-precision multi-cavity injection mold |

| Catheter Hubs | Transparent polycarbonate tooling |

| Surgical Instrument Handles | Stainless steel insert molding |

| Inhaler Casings | FDA-grade resin molding with polishing |

We designed Class III medical molds with Ra<0.05 µm polish, 420SS steel, and modular inserts. One European client increased yield by 41% while passing all EU MDR audits.

Refer to ISO 13485:2016 Summary and MedTech Dive’s Manufacturing Insights.

Metal Mold Uses in the Energy Sector

Energy equipment demands durability, corrosion resistance, and dimensional precision for field reliability and efficiency.

Metal molds support the mass production of turbine parts, battery system frames, thermal housings, and electrical connectors.

Applications in Energy Systems

| Industry Focus | Molded Components |

|---|---|

| Renewable Energy | Wind turbine connectors, PV inverter casings |

| Battery Systems | Heat sink modules, lithium shell parts |

| Power Distribution | Electrical housings, terminal guards |

| Oil & Gas | Valve seats, pressure-resistant fittings |

We built custom aluminum casting molds for a wind energy client, increasing part lifespan by 27% under outdoor exposure. Using anodized finish and tight-fit ejectors improved sealing performance.

Explore more at Energy.gov Manufacturing Innovation and IEA Clean Energy Reports.

FAQs

1. Do you support cleanroom-grade mold polishing?

Yes. We offer SPI-A1 polishing and laser texturing for medical and semiconductor applications.

2. What documentation do you provide for regulated sectors?

We provide FAI, COC, CMM reports, steel certificates, and design validation per client specs.

3. Can you use titanium or stainless steel in mold base?

Yes. We machine with 5-axis CNC and EDM using 420SS, titanium, and other tool-grade metals.

4. Do you support low-volume precision runs?

Yes. We provide prototype mold services with quick-change inserts and aluminum tools.

5. What CAD files are accepted?

STEP, IGES, Parasolid, SolidWorks, and DXF are all accepted for full toolpath generation.

Conclusion

Aerospace, medical, and energy industries demand zero-failure tooling. At Prime, we deliver certified custom molds for mission-critical parts.

We combine 20+ years of experience, ISO-certified systems, and global logistics to support high-performance production.

📞 Email: [email protected]

🌐 Website: https://primecustomparts.com

Let’s shape your next innovation—with precision, speed, and trust.