Top Welding Methods for High-Strength Custom Metal Assemblies in 2025?

I once faced welds that didn’t meet strength needs. Then I researched best methods. This guide helps you pick methods for durable assemblies.

Snippet paragraph:

You need welds that resist fatigue, stress, and corrosion. This guide compares MIG vs TIG, explains joint‑strength factors, covers fixture design, and describes finishing options. I also include real examples and sources.

Read on to learn practical methods, design advice, and finishes for assemblies built to endure.

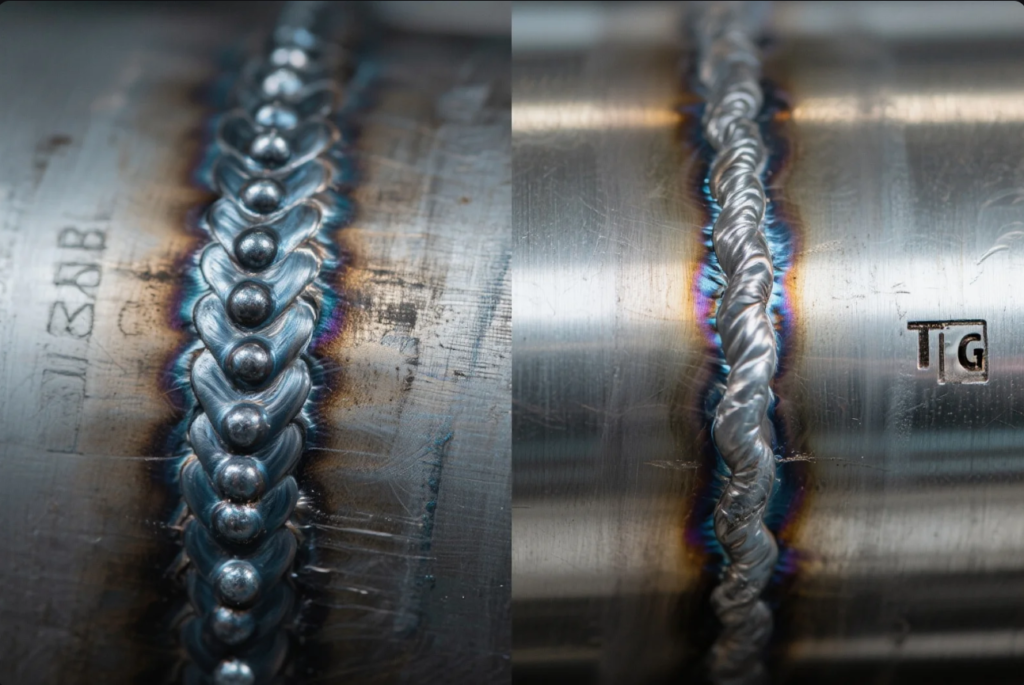

MIG vs TIG: Which Welding Process Suits Your Application?

I had to choose between MIG and TIG for structural steel. So I tested both.

Snippet paragraph:

MIG welding offers high speed and deposition rate. But it creates spatter and needs cleanup. TIG produces precise, clean seams. But it runs slower and needs skilled operators.

Welding Methods Overview

| Method | Benefits | Limitations | Best Applications |

|---|---|---|---|

| MIG Welding | Fast, efficient, great for thick metals | More spatter, less precision | Fabrication, structural steel |

| TIG Welding | Clean welds, precise, low spatter | Slower, requires skill | Thin metals, aerospace, medical |

🛠️ Learn more from the American Welding Society MIG/TIG comparison.

Global method definitions: IIW – International Institute of Welding.

Key Factors That Affect Weld Joint Strength and Durability

I once had welds fail fatigue tests. That pushed me to study weld mechanics.

Snippet paragraph:

Joint strength depends on geometry, heat input, base material, filler choice, preheat, and post-weld treatment. Ignoring even one factor can lead to early failure.

Core Factors That Matter

| Factor | Impact | Tip |

|---|---|---|

| Bead Geometry | Avoids stress points | Smooth transitions, no undercut |

| Heat Input | Affects HAZ and grain | Use low amps, water-cooled jigs |

| Filler Metal | Ensures weld strength | Match to base metal; see AWS A5.18 spec |

| Pre/Post Heat | Prevents cracking | 200–300°C stress relief for carbon steels |

| Surface Prep | Removes contaminants | Acetone wipe + brushing |

🧪 Check material compatibility with Total Materia and use NACE guidelines for corrosion-sensitive parts.

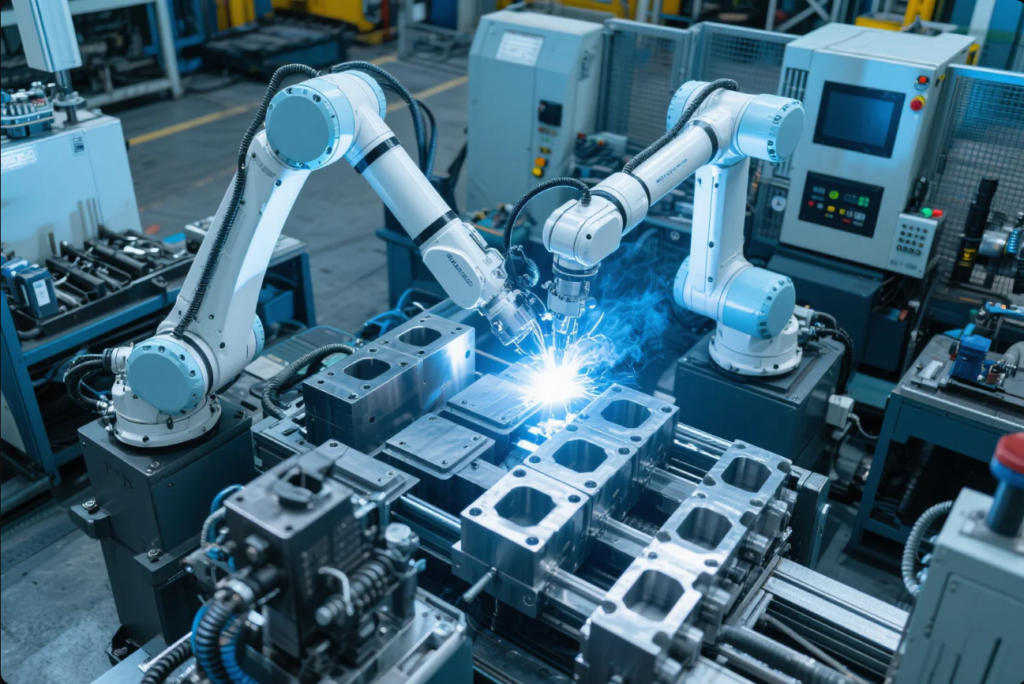

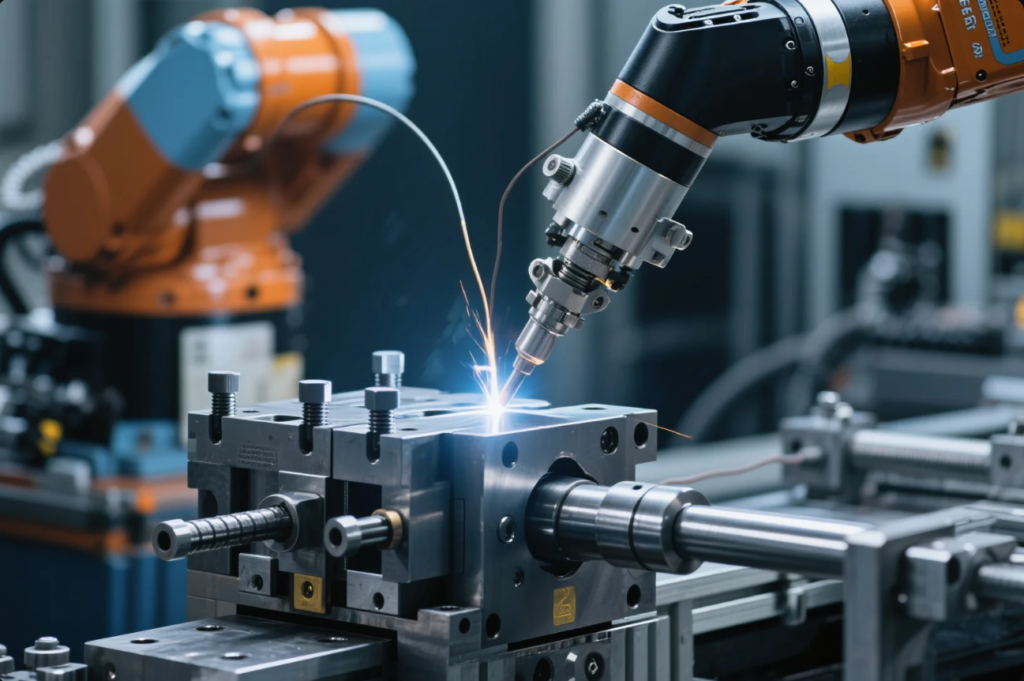

The Role of Fixture Design in Automated Welding Precision

I used to get inconsistent results until I redesigned my fixtures.

Snippet paragraph:

Fixtures control alignment, repeatability, and heat distortion. They enable robots to deliver consistent welds with minimal defects.

Key Fixture Design Guidelines

| Element | Why It Matters | How to Implement |

|---|---|---|

| Pins & Clamps | Locks parts in position | Use hardened steel for repeatability |

| Cooling Channels | Prevents warping | Especially in aluminum or thin plates |

| Quick Change Base | Speeds production | Use modular rails with quick releases |

| Grounding Design | Arc stability & safety | Connect all fixture surfaces properly |

👷 OSHA’s Welding Safety Guide includes fixturing safety advice.

🧰 Lincoln Electric’s fixture resources offer in-depth videos and design tips.

Surface Finishing Options for Welded Metal Parts

Welds should be tough and look good. Surface finishing helps with both.

Snippet paragraph:

Polishing, blasting, passivation, and coating improve durability, appearance, and corrosion resistance. Choose based on metal type and usage.

Popular Finishes for Welded Assemblies

| Process | Benefits | Ideal Metals | Tip |

|---|---|---|---|

| Grinding | Removes excess welds | All | Use flap disks under 500 RPM |

| Polishing | Smooth, shiny finish | Stainless | Progress grits from 80 to 600 |

| Sandblasting | Matte uniformity | Carbon steel | Match grit size to hardness |

| Passivation | Stops rust | Stainless steel | Use citric acid process |

| Powder Coating | Color + corrosion shield | Steel | Use zinc-rich primer underneath |

| Zinc Plating | Galvanic corrosion block | Carbon steel | Clean thoroughly before coating |

💡 Learn about passivation and powder coating processes on Wikipedia.

📘 See finishing specs at SSINA (Stainless Steel Industry Association).

FAQs

Q: Which welding method suits structural frames?

A: MIG with ER70S-6 wire offers speed and strength.

Q: Can surface treatment extend weld life?

A: Yes. Passivation, painting, or plating improve corrosion resistance.

Q: Are fixtures required for robotic welds?

A: Absolutely. They stabilize parts, reduce scrap, and save time.

Q: Is post-weld heat treatment necessary?

A: For thick or alloyed parts, yes. It reduces cracking and residual stress.

Q: What’s a good coating for marine parts?

A: Zinc plating with epoxy topcoat provides high salt spray resistance.

📞 Contact Prime

We help you create high-strength, precision-welded parts with speed and consistency.

Reach out for a free consultation or quotation.

🌐 Website: https://primecustomparts.com

📧 Email: [email protected]

Conclusion

Choose the right welding method based on your part’s geometry and strength needs. Manage heat and joint design carefully. Use smart fixtures and apply finishing for long-term performance.

Partner with PrimeCustomParts.com — a trusted supplier delivering reliable, ISO-certified welded assemblies worldwide.