Understanding Metal Parts: A Comprehensive Guide to Materials, Manufacturing, and Applications

Metal parts form the backbone of modern industry, powering everything from vehicles to buildings. These components, crafted from various metal materials through specialized manufacturing processes, play a crucial role across diverse sectors. Understanding the fundamentals of metal parts is essential for businesses seeking quality components for their products and projects.

Metal parts are essential in nearly all industries. Choosing the right material and process affects quality, performance, and cost.

Metal selection and production processes may seem complex. But a clear understanding helps reduce mistakes and improve outcomes. Let’s explore key materials, processes, and application sectors of metal components in detail.

What Are the Common Materials for Metal Parts?

Metal material choice often causes confusion. Picking the wrong one results in poor durability or higher costs.

Different alloys serve different needs. Engineers must evaluate strength, corrosion resistance, and cost when selecting materials.

Ferrous Alloys

Carbon Steel

Carbon steel remains one of the most widely used materials due to its versatility and affordability. Its properties change based on carbon content and heat treatment.

Stainless Steel

Stainless steel resists rust due to chromium content. It’s widely used where hygiene or chemical exposure matters.

Cast Iron

Includes grey, ductile, and white iron, each with specific features. Ductile iron is often used when strength and vibration damping are needed.

Non-Ferrous Alloys

Aluminum Alloys

Aluminum alloys offer excellent weight-to-strength ratios. They work well in aerospace and automotive.

Copper Alloys

Brass and bronze are useful for their conductivity and machinability.

Nickel and Titanium Alloys

Titanium alloys provide top corrosion resistance and strength. They are widely used in aerospace and medical implants.

Material Selection Checklist

- Will the part face heat or chemicals?

- Does the application require lightweight?

- What are budget limits?

- Will the part be machined, cast, or stamped?

- Are certifications like ISO 9001 required?

What Are the Key Manufacturing Methods for Metal Parts?

Using the wrong production method often leads to longer lead times and higher defect rates.

Casting, forging, stamping, and machining each offer different precision, cost, and strength.

Casting Processes

Sand Casting

Ideal for large parts, sand casting offers flexibility and low cost.

Investment Casting

Known for high precision. Used in medical and aerospace.

Learn more about investment casting

Die Casting

For high volumes and tight tolerances, die casting is widely preferred in automotive.

Forming Processes

Forging

Creates strong, fatigue-resistant parts. Common in tools and engines.

Stamping and Pressing

Best for high-volume, thin-metal parts.

Tip: Use ISO-certified stamping suppliers to reduce quality risks

Machining Processes

Turning and Milling

Used for detailed, precise components. CNC-controlled processes allow consistent quality.

Understand CNC machining processes

Advanced Methods

Metal 3D Printing

Enables lightweight structures and custom geometries.

EDM

Works on hard materials. Ideal for precision die-making.

Compare Process Capabilities

| Process Type | Cost Efficiency | Precision | Surface Finish | Volume |

|---|---|---|---|---|

| Sand Casting | High | Low | Rough | High |

| CNC Machining | Medium | High | Fine | Low |

| Die Casting | High | Medium | Good | Very High |

| 3D Printing | Low | Very High | Excellent | Low |

What Key Properties Should I Look for in Metal Parts?

Without knowing required properties, selecting parts becomes trial and error.

Strength, hardness, corrosion resistance, and ductility define part performance under real-world use.

Key Property Categories

- Mechanical: Hardness, strength, ductility

- Thermal: Conductivity, resistance to heat

- Chemical: Corrosion and oxidation resistance

- Electrical: Conductivity, especially for copper-based alloys

Which Industries Use Metal Parts the Most?

Understanding usage helps predict wear, environmental conditions, and required standards.

Different industries need different combinations of performance, safety, and reliability.

Industry-Specific Examples

- Automotive: Engine, suspension, battery enclosures

- Aerospace: High-temp turbine parts, lightweight frames

- Medical: Titanium implants, stainless surgical tools

- Energy: Pressure-resistant casings, corrosion-proof tubing

Certifications Often Required

How Should I Select a Metal Parts Supplier?

Poor supplier selection leads to late delivery, inconsistent quality, and wasted cost.

A good supplier understands engineering needs, meets international standards, and communicates clearly.

Key Factors When Choosing

- Check ISO certification

- Inspect manufacturing capacity

- Evaluate communication effectiveness

- Request samples and test results

- Confirm packaging and logistics capability

- Ask for RoHS or REACH compliance if needed

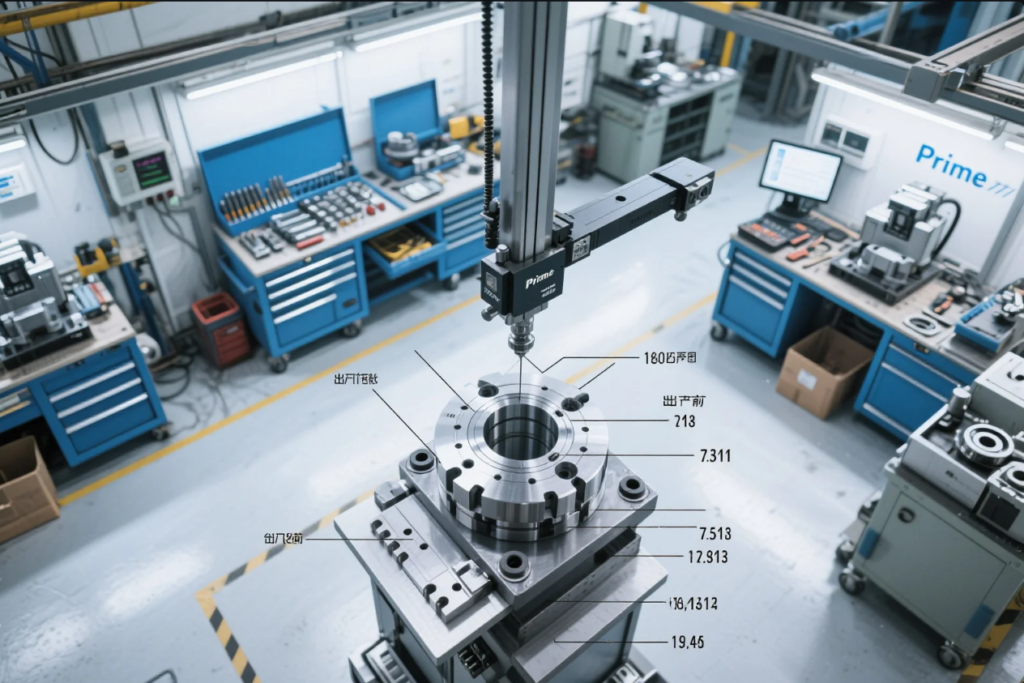

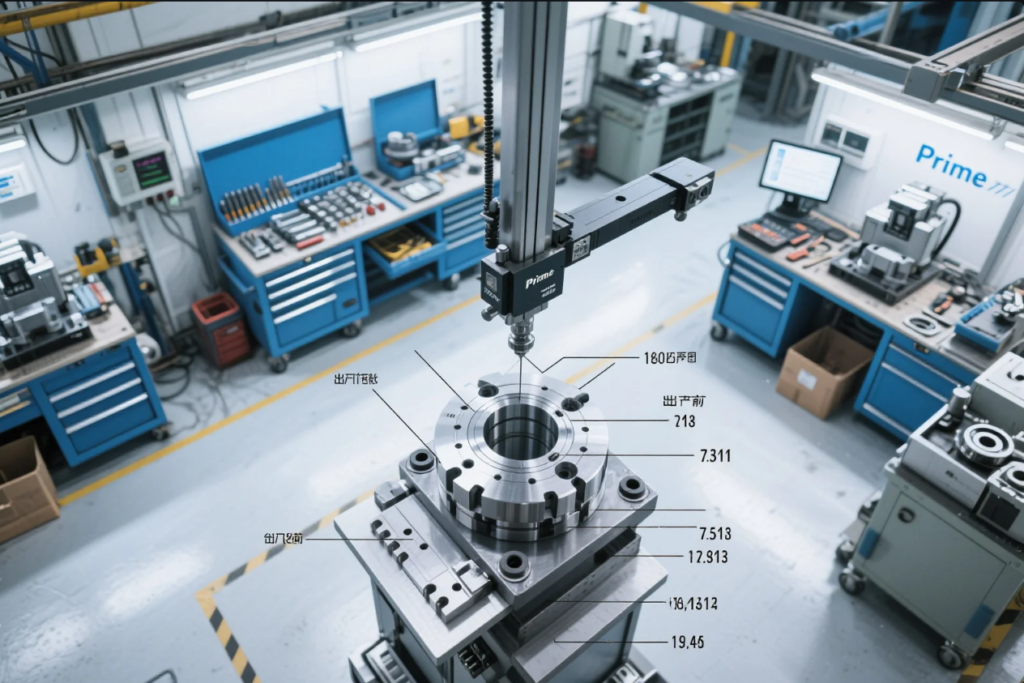

Why Work With Prime?

At Shandong Prime International Trade Co., Ltd., we:

- Hold full ISO quality certifications

- Offer custom services for stamping, CNC, casting, and more

- Export to North America, Europe, and the Middle East

- Support low MOQ, fast lead times, and strict packaging control

- Operate 10+ in-house production lines

- Serve large OEMs, engineers, and global traders

Explore our full capabilities on our official website

What Are the Latest Trends in Metal Parts Manufacturing?

New technologies help reduce waste, cost, and time-to-market.

Lightweighting, additive manufacturing, and digital twins change how we design and source components.

Trends to Watch

- Lightweight design with alloys and hollow structures

- Simulation-driven design optimization

- Use of recycled metals

- Smart factories and predictive maintenance

- Expansion of metal additive manufacturing

Conclusion

Metal part quality depends on material, manufacturing, and supplier. Choose wisely to avoid failure and delays.

Looking for a reliable supplier of ISO-certified precision metal parts?

Reach out to Prime today for a free quote and expert consultation.Understanding Metal Parts Let us help with fast delivery, strict quality control, and custom solutions tailored to your needs. Visit our website or contact our sales team directly.