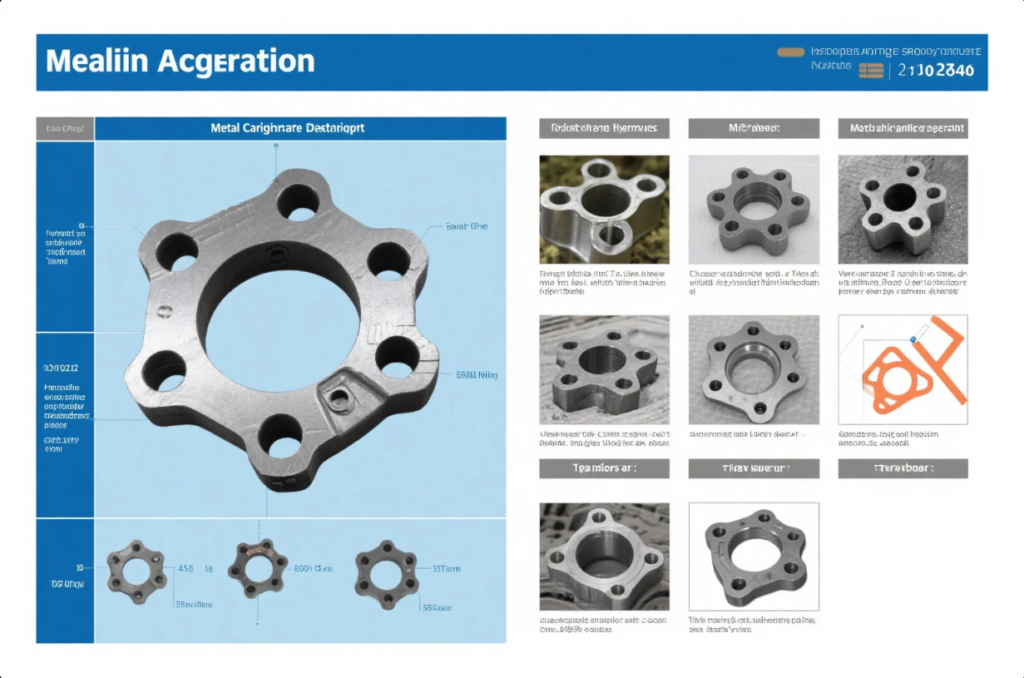

Understanding Sand Casting for Complex Metal Parts

Sand casting is one of the oldest yet most versatile metal forming processes in modern industry. Known for its simplicity and adaptability, sand casting is widely used to produce complex metal parts for various industries including automotive, aerospace, energy, and heavy equipment. This in-depth guide explores how sand casting works, its benefits for small-to-medium batch production, material compatibility, defect prevention, and industry applications. Whether you’re sourcing custom components or comparing manufacturing options, understanding sand casting is key to making the right choice.

What Is Sand Casting?

Sand casting is a metal casting process that uses sand to create molds into which molten metal is poured. The process begins with a pattern that forms the mold cavity, then progresses through a series of steps to produce a final part that closely matches the original design.

The process is cost-effective for producing:

- Large metal parts

- Intricate geometries

- Prototypes and limited production runs

🔗 Learn more at Wikipedia: Sand Casting

Advantages of Sand Casting for Small to Medium Batches

Sand casting provides several distinct benefits, especially for custom orders and medium-volume production.

✔️ 1. Low Tooling Costs

Sand molds are made using inexpensive materials like silica or chromite sand and clay. This makes sand casting ideal for:

- Prototypes

- Small-batch production

- Custom modifications

✔️ 2. Flexibility in Size and Complexity

Parts from 0.1 kg to several tons can be made using the same process, with little additional tooling.

✔️ 3. Material Versatility

Almost all ferrous and non-ferrous metals can be used. This is beneficial for diverse industrial applications.

✔️ 4. Ideal for Irregular Shapes

Sand casting easily accommodates:

- Internal cavities

- Undercuts

- Hollow features using cores

✔️ 5. Scalable and Sustainable

The sand used in the mold can often be reclaimed and reused multiple times.

🔗 TWI Global: Benefits of Sand Casting

Materials Used in Sand Casting

A major advantage of sand casting is its compatibility with a wide range of metals and alloys:

🟠 Gray and Ductile Cast Iron

- Excellent wear resistance

- Good damping properties

- Used in engine blocks, machine bases

🟢 Aluminum Alloys (A356, A319)

- Lightweight

- Good thermal conductivity

- Common in automotive and aerospace components

🔵 Carbon and Alloy Steels

- High tensile strength

- Ideal for load-bearing components

🟡 Bronze and Brass

- Corrosion resistance

- Decorative and functional components

🔗 Total Materia: Common Cast Metals

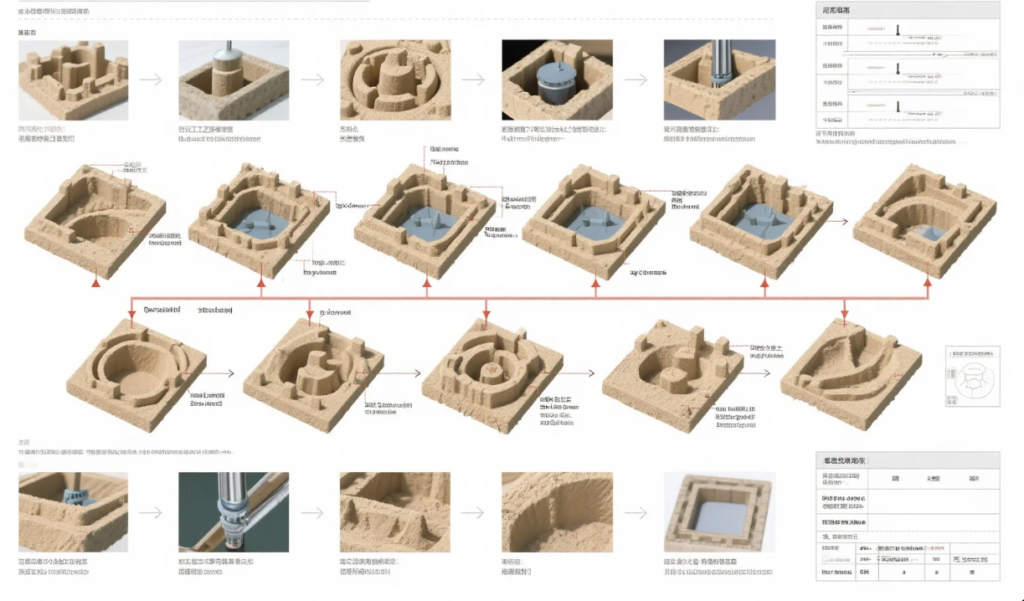

The Sand Casting Process in Detail

Here’s how sand casting typically works:

- Pattern Making – A pattern (model) of the part is created.

- Mold Making – Sand is packed around the pattern in a flask.

- Core Setting – Cores are placed for internal features.

- Pouring – Molten metal is poured into the mold cavity.

- Cooling – Metal solidifies into shape.

- Shakeout – The mold is broken and casting is removed.

- Cleaning & Finishing – Surface finishing, trimming, and machining.

🔗 EngineeringNotes: Sand Casting Steps

Design Considerations in Sand Casting

To ensure a successful cast part, engineers must consider:

- Draft angles: Prevents damage during mold removal.

- Wall thickness: Uniform thickness minimizes stress and shrinkage.

- Core design: Critical for parts with hollow sections.

- Riser and gating system: Ensures full cavity fill and solidification.

How to Avoid Common Casting Defects

Defects in sand casting may result from poor mold design, improper pouring, or material issues.

🔍 Common Defects Include:

- Shrinkage cavities

- Cold shuts

- Gas porosity

- Sand inclusions

✅ Solutions:

- Use quality sand with appropriate moisture

- Optimize venting and risers

- Control pour temperature and speed

- Apply mold coatings for smoother surfaces

🔗 EngineeringChoice: Types of Casting Defects

Applications: Where Sand Casting Excels

Sand casting is used to make critical parts in:

🚗 Automotive Industry

- Cylinder heads

- Engine blocks

- Brackets and supports

✈️ Aerospace

- Ducting systems

- Housing components

⚙️ Heavy Equipment

- Valve bodies

- Pumps

- Structural elements

🏭 Power & Energy

- Wind turbine housings

- Generator parts

🔗 Reliance Foundry: Industrial Casting Applications

Why PrimeCustomParts.com is Your Best Choice

With over 20 years of experience, Prime delivers excellence in every cast:

- 🌍 Exporting globally to North America, Europe, Middle East, and Australia

- 🏭 10 production lines with ISO 9001-certified quality

- 💡 Rapid prototyping and technical support

- 🧰 Custom tooling and tight tolerance control

- 📨 Fast response and transparent communication

FAQs

Q1: How precise is sand casting?

A: Tolerances of ±0.5–2 mm are standard; tighter dimensions achieved via machining.

Q2: Can I provide my own alloy specification?

A: Yes, custom alloy compositions can be produced on request.

Q3: What surface finish can I expect?

A: Ra 6.3–12.5 µm is typical; better finishes can be achieved post-processing.

Q4: How long is the production cycle?

A: 2–4 weeks depending on complexity and order size.

Q5: What is the maximum size of parts you can produce?

A: We cast parts from 100 g to several tons.

Contact Us

📧 Email: [email protected]

🌐 Website: https://primecustomparts.com

📍 Shandong Prime International Trade Co., Ltd.

Let’s bring your custom parts to life.