What Aluminum Cannot Be Welded?

Not all aluminum is weldable—choosing the wrong alloy leads to cracks, porosity, and total weld failure.

High-strength aluminum alloys like 2024 and 7075 are difficult or impossible to weld effectively using conventional methods.

Let’s explore which aluminum types cause the most welding problems—and how to avoid costly mistakes.

What type of aluminum is not weldable?

Some aluminum grades will crack no matter how good the welder is.

Aluminum alloys in the 2xxx and 7xxx series—like 2024 and 7075—are considered non-weldable.

Why some aluminum alloys resist welding

These alloys contain high amounts of copper or zinc, which creates challenges:

- Prone to hot cracking in the heat-affected zone

- Low weld strength compared to the parent metal

- Oxide formation interferes with fusion

I’ve had clients request welded parts in 7075. We always recommend mechanical fastening or redesign using 6061-T6, which welds far better and maintains strength.

Table: Weldability of Common Aluminum Alloys

| Alloy Series | Example Alloy | Weldability | Common Use |

|---|---|---|---|

| 2xxx | 2024 | Poor | Aircraft structures |

| 7xxx | 7075 | Very Poor | Aerospace, bikes, defense |

| 6xxx | 6061-T6 | Good | Structural parts, frames |

| 5xxx | 5052 | Excellent | Marine, tanks, pressure vessels |

At Prime, we always guide customers to weld-friendly aluminum grades and offer CNC pre-cut options that improve welding outcomes and production time.

What’s the worst metal to weld?

Some metals just don’t cooperate—no matter what process you use.

Metals like cast iron, lead, and high-zinc aluminum alloys are notoriously difficult to weld.

Why certain metals resist welding

In my 20+ years of metal processing, the worst welding results almost always involve:

- Porous or brittle base materials

- Incompatible thermal expansion rates

- Toxic fumes or reactivity under heat

This includes some aluminum alloys, but also materials like galvanized steel and magnesium.

Table: Worst Metals to Weld

| Metal | Welding Difficulty | Main Problem |

|---|---|---|

| 7075 Aluminum | Very high | Hot cracking |

| Cast Iron | High | Brittle structure, cracks |

| Lead | Extremely high | Toxic fumes, low melting point |

| Galvanized Steel | High | Fumes from zinc coating |

| Magnesium | High | Flammable, oxidizes rapidly |

At Prime, our ISO-certified welding team carefully screens all incoming jobs. For difficult materials, we often suggest alternatives or hybrid assembly methods to ensure safety and performance.

Can all aluminum be welded?

It’s a common myth that all aluminum grades weld the same way.

No, not all aluminum can be welded—some alloys suffer from cracking, distortion, or fusion failure.

Factors that affect aluminum weldability

The main issue isn’t just the metal—it’s the chemistry and intended heat treatment.

Key challenges:

- High-strength alloys lose mechanical properties after welding

- Copper-rich or zinc-heavy grades tend to crack under heat

- Aluminum’s oxide layer must be removed before welding

Table: Weldability Checklist for Aluminum

| Factor | Impact on Weldability |

|---|---|

| Alloy series (2xxx, 7xxx) | Low weld success rate |

| Heat treatment status | Alters strength after welding |

| Thickness and fit | Affects heat input needed |

| Cleaning and prep | Crucial for quality welds |

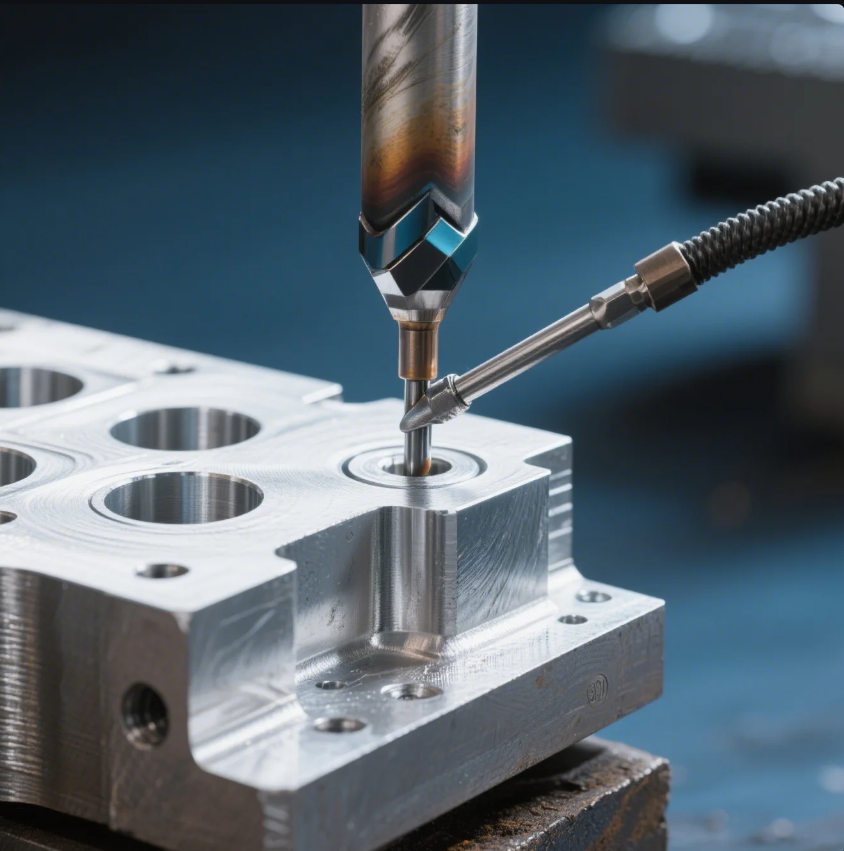

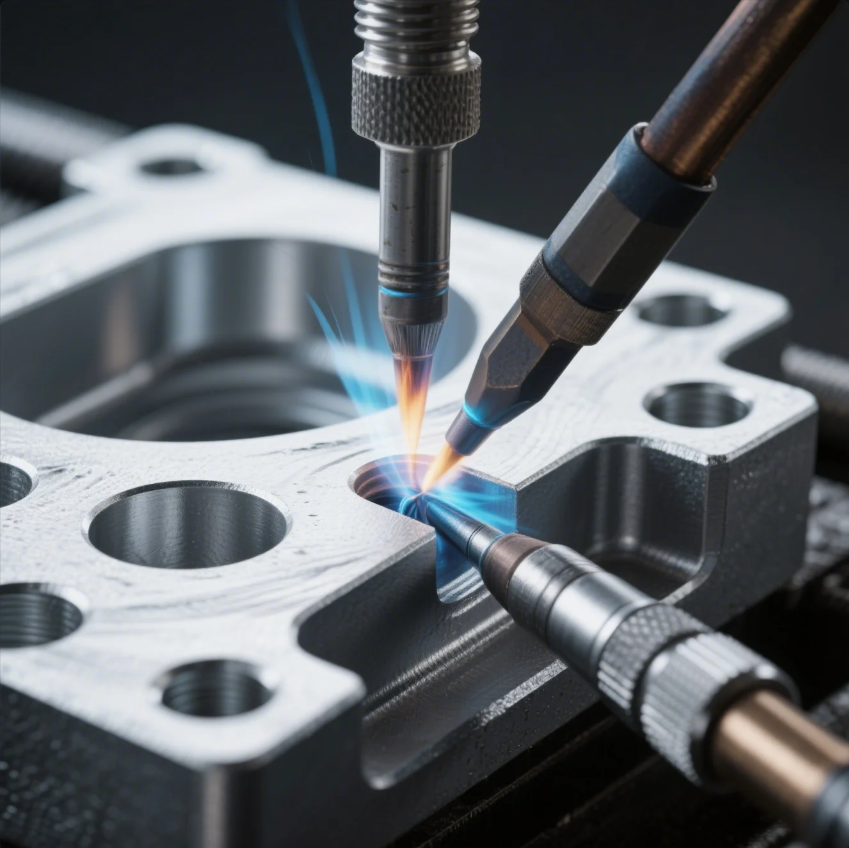

At Prime, we use TIG or MIG with advanced surface prep and recommend only weld-compatible aluminum blanks, especially for global clients seeking repeatable quality.

Can you use an arc welder for aluminum?

Arc welding aluminum sounds simple—but it rarely works well in practice.

Yes, you can use an arc (stick) welder for aluminum, but it’s rarely recommended due to poor quality and inconsistency.

Why stick welding aluminum is a bad fit

In theory, with the right electrode—like E4043—you can stick weld aluminum. But in reality, the process is:

- Messy with lots of spatter

- Prone to porosity and cracking

- Very hard to control on thin sections

This method might work for emergency field repairs, but not for any precision or industrial application.

Table: Arc Welding vs. MIG/TIG for Aluminum

| Method | Weld Quality | Speed | Best Use |

|---|---|---|---|

| Stick (SMAW) | Low | Medium | Field repair only |

| MIG | Medium-High | High | Production, thick parts |

| TIG | Very High | Low | Precision, thin parts |

At Prime, we advise our clients to avoid stick welding for aluminum unless there’s no alternative. We offer certified MIG/TIG services for quality assurance and performance durability.

Conclusion

Aluminum alloys like 2024 and 7075 are nearly impossible to weld—but Prime helps you choose the right material every time.

Need help picking weldable aluminum for your next project?

Contact Prime now for expert guidance, material selection, and certified welding services.

We provide fast delivery, ISO-compliant quality, and one-on-one technical consultation—so you always get it right the first time.