What are CNC machined parts?

CNC machined parts are a fundamental component in modern manufacturing, used in a wide range of industries. But what exactly are CNC machined parts? In this article, we will explain what CNC machining is, how it works, and the role it plays in producing high-precision components.

CNC machining allows for the precise production of complex parts. Understanding this process can help you choose the right machining solution for your needs. Let’s explore the key concepts behind CNC machined parts.

With over 20 years of experience in CNC machining, Prime has been delivering high-quality custom CNC parts for global clients. Let’s dive into the world of CNC machining and discover how it shapes the manufacturing industry.

What is CNC machined parts?

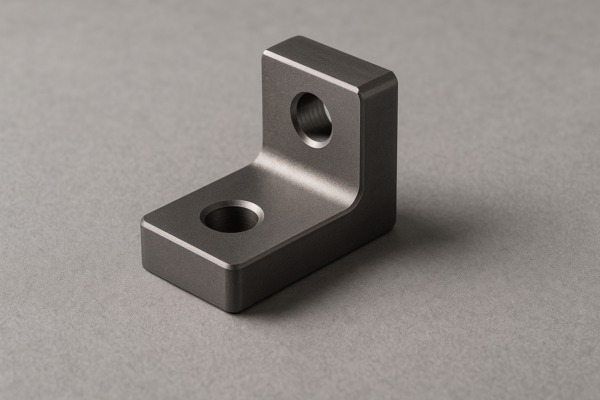

CNC machined parts are components created through the process of Computer Numerical Control (CNC) machining. This process involves using computers to control machine tools that cut, shape, and finish materials with high precision. CNC machined parts can be made from a variety of materials, including metal, plastic, and composites.

Snippet paragraph: CNC machined parts are components created by using computer-controlled machines. These parts are known for their precision and versatility across multiple industries.

Precision and Versatility

The primary benefit of CNC machining is the high level of precision it offers. The parts produced through CNC machining are often used in industries where accuracy is critical, such as aerospace, automotive, and medical device manufacturing. CNC machines are capable of creating highly complex shapes with tight tolerances.

- Key Benefits: Precision, repeatability, and the ability to create complex geometries.

- Common Materials: Metals (aluminum, steel, titanium), plastics (nylon, polypropylene), composites.

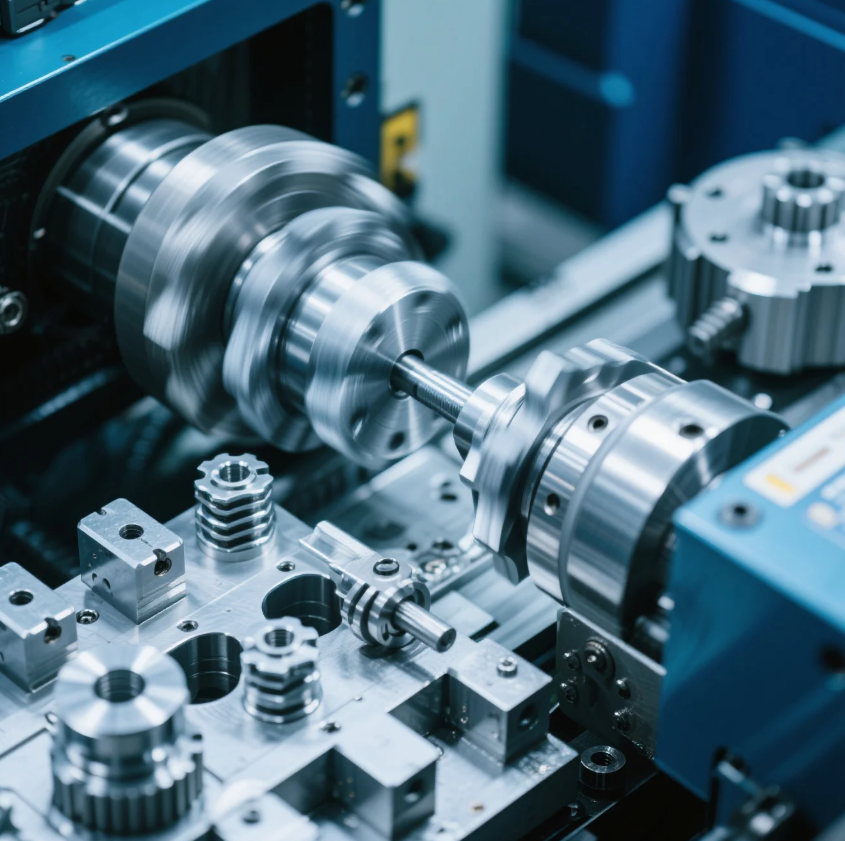

Types of CNC Machines

There are several types of CNC machines used for machining different parts. Common types include CNC mills, CNC lathes, CNC routers, and CNC EDM (Electrical Discharge Machines). Each of these machines is designed to handle specific tasks, such as milling, turning, or drilling.

What does CNC machining do?

CNC machining is a manufacturing process that uses pre-programmed computer software to control the movement of tools and machines. It removes material from a workpiece to create the desired shape or component.

Snippet paragraph: CNC machining uses computer software to control tools and machines. It removes material from a workpiece to create high-precision components with complex shapes.

The Process of CNC Machining

-

Design: The part is first designed using CAD (Computer-Aided Design) software. The design is then converted into a set of instructions (G-code) that CNC machines can understand.

-

Tool Setup: CNC machines are equipped with various tools, such as drills, cutters, and mills, that are selected based on the required task.

-

Machining: The CNC machine executes the program, moving the tools to remove material from the workpiece. This process can include cutting, drilling, turning, or milling, depending on the part’s design.

-

Finishing: Once the part is shaped, it may undergo further processes, like polishing or coating, to improve its appearance and functionality.

Benefits of CNC Machining

- High precision: CNC machining can achieve extremely tight tolerances.

- Flexibility: CNC machines can handle a wide range of materials and part complexities.

- Automation: Once set up, CNC machines can run with minimal operator intervention, increasing efficiency.

What are the examples of CNC machine?

CNC machines come in various types, each designed to perform specific tasks. Some common examples include CNC mills, CNC lathes, and CNC routers.

Snippet paragraph: Examples of CNC machines include CNC mills, lathes, and routers. Each machine serves a unique purpose based on the type of workpiece and desired result.

CNC Mills

CNC milling machines are used to perform operations like drilling, boring, and cutting. They use rotating tools to remove material from the workpiece. These machines are ideal for creating complex 3D parts and are widely used in industries like aerospace, automotive, and medical manufacturing.

- Function: Drilling, cutting, and shaping materials.

- Common Uses: Aerospace components, automotive parts, medical devices.

CNC Lathes

CNC lathes are machines that rotate the workpiece, while a fixed cutting tool is used to remove material. This is primarily used for creating cylindrical parts like shafts, pins, and tubes. CNC lathes are ideal for high-precision turning operations.

- Function: Turning and shaping cylindrical parts.

- Common Uses: Shafts, bolts, tubes.

CNC Routers

CNC routers are used to cut, carve, or engrave a variety of materials. They are commonly used for larger parts or when precision is not as critical. CNC routers are typically used in wood, plastic, and composite materials.

- Function: Cutting and carving materials.

- Common Uses: Woodworking, sign-making, plastic parts.

CNC EDM Machines

CNC Electrical Discharge Machines (EDM) use electrical sparks to remove material from the workpiece. This is ideal for hard materials like tool steel and for parts that require extremely precise cuts.

- Function: Precision cutting using electrical sparks.

- Common Uses: Tool-making, high-precision components.

What are machined components?

Machined components are parts that have been precisely manufactured using machining processes such as CNC machining. These components are typically made from materials like metals or plastics and are often used in critical applications where high precision is required.

Snippet paragraph: Machined components are parts made using machining processes like CNC. These parts are precise and often used in critical industries like aerospace, automotive, and medical.

Types of Machined Components

Machined components can range from simple parts like brackets or spacers to complex, high-precision components like engine blocks, gears, or medical implants. Some common machined components include:

- Gears: Precision gears used in machines and vehicles.

- Valves: Used in automotive and industrial machinery.

- Bearings: Critical for reducing friction in moving parts.

- Cylinders: Common in automotive and industrial applications.

Applications of Machined Components

- Aerospace: High-precision components like turbine blades and engine parts.

- Automotive: Parts like engine blocks, pistons, and transmission gears.

- Medical Devices: Implants, surgical tools, and diagnostic equipment.

Conclusion

CNC machined parts are crucial in modern manufacturing due to their precision and versatility. Whether it’s creating automotive components or aerospace parts, CNC machining ensures high-quality results. At Prime, we specialize in CNC machining for a variety of industries. Contact us today for a quote, and let us help you with your next custom CNC part.