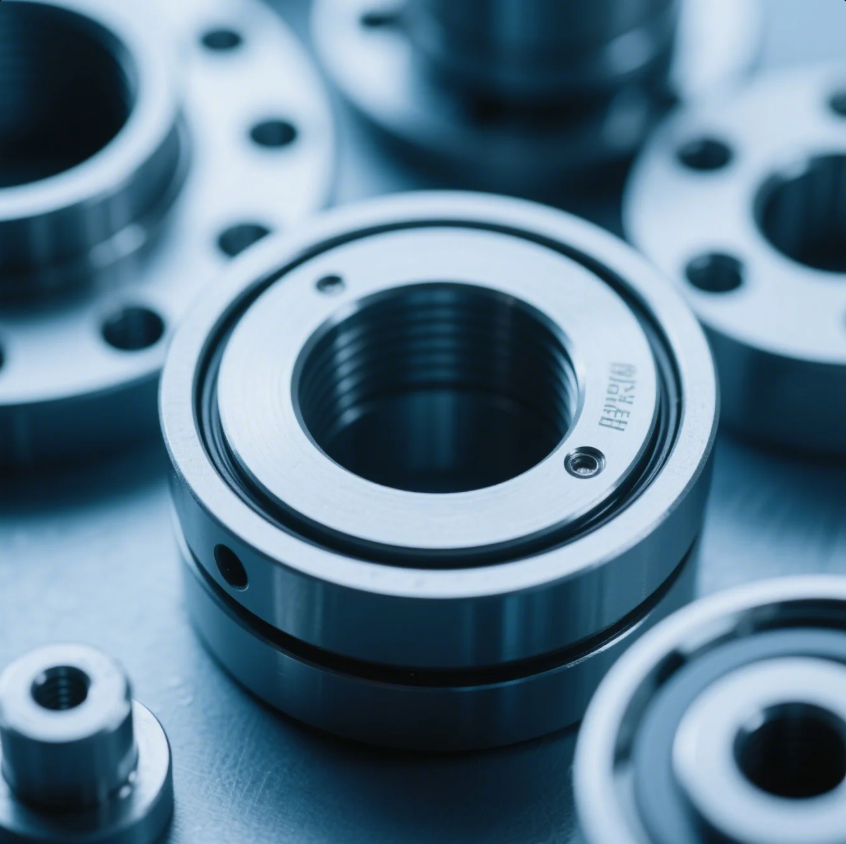

What Are Mechanical Seal Parts?

Leaks in rotating equipment cause downtime and expensive repairs.

Mechanical seal parts prevent fluid leakage by sealing the rotating shaft and stationary equipment housing.

Many engineers choose mechanical seals to boost efficiency and reduce failures.

What Are Mechanical Seals Used For?

Rotating machines often leak without proper sealing.

Mechanical seals are used to stop fluid leakage in pumps, mixers, and compressors.

Why Industrial Machines Depend on Mechanical Seals

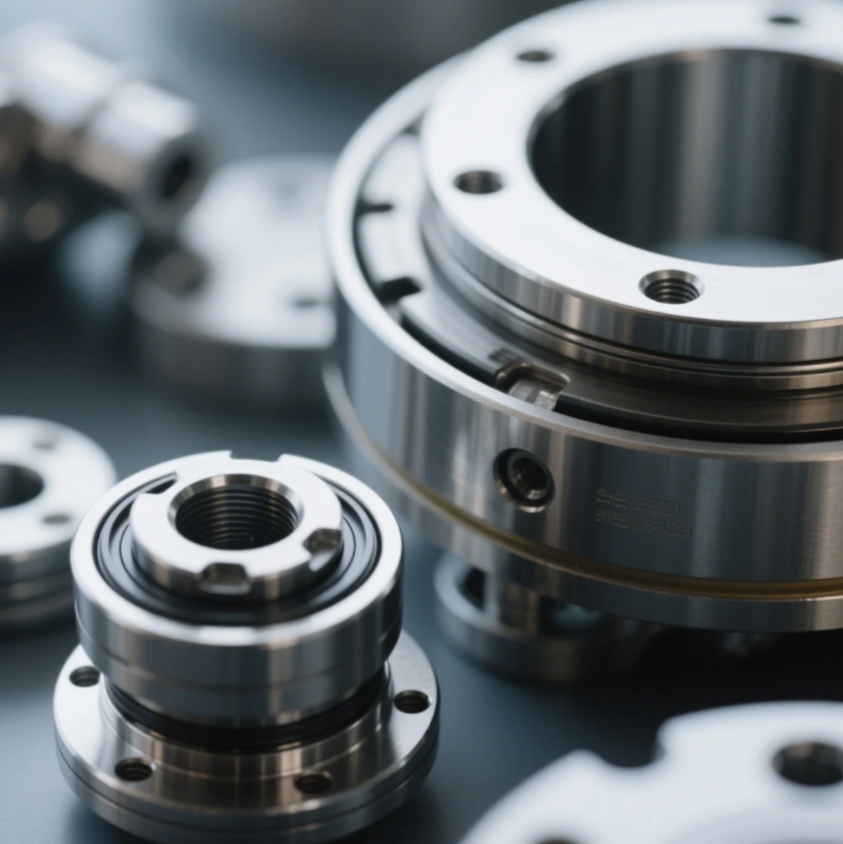

In many industries, rotating machines operate under pressure or with aggressive fluids. Mechanical seals offer tight, reliable sealing at the point where a shaft enters a chamber. Unlike packing seals, mechanical seals use smoother contact and last longer.

Applications Across Industries

| Industry | Use of Mechanical Seals |

|---|---|

| Chemical Processing | Sealing toxic and corrosive fluids |

| Oil & Gas | Handling high pressures and heat |

| Food & Beverage | Preventing contamination |

| Water Treatment | Controlling leaks in pumps |

At Prime, our custom CNC parts, precision-machined fasteners, and ISO-certified casting parts integrate with sealing systems to support rotating equipment across global industries. We manufacture critical seal components to match customer-specific needs.

What Are the Basics of Mechanical Seals?

Engineers often struggle with choosing the right sealing system.

Mechanical seals consist of a rotating face, stationary face, secondary seals, and hardware.

Understanding Key Components

Every mechanical seal has four major parts:

- Rotating Face: Usually attached to the shaft and spins with it.

- Stationary Face: Remains fixed to the seal housing.

- Secondary Seals: O-rings or gaskets that prevent bypass leakage.

- Spring or Bellows: Keeps the seal faces pressed together.

How Each Part Works Together

| Part Name | Function in Sealing |

|---|---|

| Seal Faces | Create a micro-film to reduce friction |

| Secondary Seals | Fill the gaps between hard surfaces |

| Springs/Bellows | Compensate for misalignment and wear |

| Hardware | Holds all components in place |

Prime’s custom CNC machining allows us to produce these components to micron-level tolerances. Our seals meet strict specs for critical industries, especially where fluid isolation and heat resistance are non-negotiable.

Why Use a Mechanical Seal?

Packing seals wear out fast and need constant maintenance.

Mechanical seals reduce leakage, increase equipment life, and require less maintenance than traditional sealing.

The Value Mechanical Seals Bring

Mechanical seals offer several benefits over older methods like packing:

- Lower Leakage Rates: More control and less waste

- Less Friction: Lower energy costs and heat

- Longer Equipment Life: Fewer breakdowns

- Cleaner Operations: Essential in food or pharma

They’re especially useful in systems that must run continuously or under pressure. When paired with custom metal parts from Prime, these seals offer unmatched performance in real-world conditions.

Comparing Sealing Options

| Sealing Method | Pros | Cons |

|---|---|---|

| Packing Seals | Cheap, easy to install | Wears fast, leaks more |

| Mechanical Seals | Clean, durable, efficient | Higher upfront cost |

At Prime, we help buyers choose the right combination of sealing and component support. Our ISO-certified metal stamping and precision-machined sealing seats give mechanical seals the reliable base they need.

What Is a Seal in Mechanics?

Many mechanical systems fail because of minor leaks.

In mechanics, a seal is any device used to block or contain fluid, gas, or particles inside a system.

Types of Mechanical Seals and Where They Fit

Seals come in many forms: mechanical face seals, lip seals, O-rings, and gaskets. Mechanical face seals are used in rotating shafts, while gaskets are more common in bolted joints. The goal is always the same: prevent unwanted flow or contamination.

Choosing the Right Seal

| Type of Seal | Best Use Cases |

|---|---|

| Mechanical Seals | Pumps, compressors, agitators |

| O-Rings | Hydraulic or pneumatic systems |

| Gaskets | Flanged connections |

| Lip Seals | Automotive axles or rotating shafts |

We at Prime understand how small component differences affect large outcomes. That’s why we offer custom fasteners, precision plastic parts, and machined sealing parts to match your unique machinery and operating conditions.

Conclusion

Mechanical seal parts play a critical role in protecting equipment from failure and fluid loss.

Contact Prime today to get expert help choosing the right mechanical seal components. We provide fast delivery, customized solutions, and ISO-certified quality—all from our experienced one-stop factory. Let’s keep your equipment sealed and running strong.